The first few sections here are reprised (with edits) from

“Just Mooning Around”,

posted 7-14-19.

This year has been the 50th anniversary of the

first man on the moon. That was the

culmination of the space race between the US and Soviet Russia. That accomplishment was a whole lot more

about “flags and footprints” and experimental flight test, than it was about science or real exploration.

This article builds upon some earlier articles posted upon

this site. It presents the latest

version of my Mars mission outline plan,

with an enlarged manned transport,

and the latest sizing of 1-stage 2-way reusable chemical landers. These earlier articles are as follows:

Date Title

14 July 2019 Just

Mooning Around

28 May 2016 Mars

Mission Outline 2016

13 December

2013 Mars Mission Study 2013

31 August 2013 Reusable

Chemical Mars Landing Boats Are Feasible

Why We Should Go Back (And Farther Still)

Is there anything worthwhile to accomplish out there? Yes,

definitely!

In the longer term,

there are those future off-world settlements and the associated future

economies. I cannot tell you the details

of how this might benefit us, because it

has yet to be done. But it has always

proven beneficial in prior centuries here on Earth.

In the shorter term,

there are the possibilities of space resource businesses, and of planetary protection against

rogue asteroid and comet impacts. That

second item is the most important of all:

there is simply no better reason for continuing both unmanned and manned

space programs than finding ways to protect the folks back home!

It’s not about winning some race, and it’s not so very much about doing pure

science just for the sake of knowledge.

It’s about real exploration of the unknown, something hard-wired into humans. In centuries past, this was exploration of the unknown parts of

the Earth. Now it is about space and the

deep ocean floor. This article is

concerned with the real exploration of space.

“Exploration” is a really an emotionally-loaded code word, something most people do not think about. What it truly means is you go there to

find out “what all is there” (resources,

including those you don’t at first recognize), and “where exactly it is” (how hard to obtain, as well as how much is there). Then you have to stay a while to figure

out how to use what you found, in

order to cope with living in the local environment. All of that is part of “real exploration”.

Unless you do that correctly, there is no real possibility of future

settlements and the associated future economies, or any of the benefits that would ultimately

derive therefrom! There is no way to

accomplish much of anything else, except

just the “flags and footprints” act of going there and returning (which is the

bulk of what Apollo itself really accomplished at the moon).

Those who “get there first” do tend to do a little better in

the long run, in terms of those benefits, provided that they do it “right” when they go. That is one crucial lesson from history.

My Suggestions for the Near Term

Establish a continuous human presence on the moon, the first item. Start small and expand it slowly over time. Do

the lunar “exploration” thing right,

this time.

Send humans to Mars as the fulfillment of a dream centuries

old, probably the second item. When we go,

do the “exploration” thing right,

from the very first landing. Further, it starts long before the first item (going

to the moon) is “done” in any sense of that word.

But, any vehicle

capable of taking crews to Mars can also take a crew to near-Earth asteroids

and comets. Visit those asteroids and

comets and properly explore them, in

order to learn how to defend against their impacting Earth, as well as “ground truth” for how to really do

space mining.

That’s the third item,

but it is just as easily done,

and at least as important, as

going to Mars.

Maybe we do them at pretty

much the same time.

Ethically and Responsibly Addressing Known Risks For Spaceflight

We are ethically-bound to address the known risks of manned

spaceflight as best we can. There is

a whole long list of safety risks associated with any sort of manned spaceflight. Three come to mind as the most truly credible

risks: (1) reliability of, and escape from, spacecraft and booster rockets, (2) microgravity diseases, and (3) exposure to space radiation.

The first one has cost us three American crews totaling 17

people dead (Apollo 1, shuttle Challenger, and shuttle Columbia). Each caused a year-or-more stand-down, and very expensive investigations, plus very expensive changes.

The two shuttle losses were ultimately caused by bad

management decisions valuing cost or schedule above safety. Apollo 1 was about a really-poor basic

management attitude (“good enough for government work”) combined with technical

ignorance, because we had never done

this sort of thing before.

Those outcomes and their actual causes are why I claim

“there is nothing as expensive as a dead crew,

especially one dead from a bad management decision”. Bear in mind that those expenses are both

economic and political (which includes public opinion as well as DC politics).

Making spaceflight more safe, from a reliability and escape standpoint, is now also something we already know how to

address! This takes careful design

allowing for failure modes, redundant

systems, and copious verification

testing. Mitigation efforts will

never be perfect, but they can be quite

good. Ethics requires that you treat this as a required constraint

upon your designs.

It means you always provide “a way out” for your crew

at every step of the mission. It

really is as simple (and as hard to do) as that! This very seriously constrains your

overall mission architecture, as well as

your detailed space vehicle designs.

The other two have been long studied in low Earth

orbit, where microgravity exposure is

inherent in everything we have done there,

and radiation exposure is somewhat more than on Earth’s surface, but less than outside the Van Allen radiation

belts (and far less than inside the belts themselves).

Microgravity

Diseases

Microgravity has proven to affect the human body in a

variety of expected, and unexpected,

ways.

The longer one is exposed, the

worse the various diseases become. Beyond

the bone decalcification and muscle-weakening that we have long expected, there are also degradations of the heart and

circulatory system, degradation of

vision from eye geometry changes due to the fluid pressure redistribution, immune system degradations that we have yet

to understand, and most recently genetic

changes whose meanings are still a total mystery. No doubt more will be discovered, as that has been the trend.

The longer exposed,

the longer it takes to recover upon returning home, with full recovery actually still in doubt

for some of the effects, despite

diet, drugs, and exercise. The practical time limit

seems to be only a bit more than a year. For that very reason, usual practices on the International Space

Station (ISS) call for 6 months to a year’s exposure at most, with 6 months the preferred limit.

We do know that something near one full Earth gravity (one

“gee”) is therapeutic, precisely because

that is what we evolved in. So, until we know better, any artificial spin gravity schemes

need to supply very near one gee,

in order to obtain the full Earthly benefits that we already know will work.

Destinations outside of Earth-moon space are very much

further away than the moon: one-way

travel times range from near 6 months to multiple years. This is pretty much outside the preferred limit

of microgravity exposure that we have already established on ISS.

Mars is 6-to-9 months away one-way, and we do not know how therapeutic its

lower gravity (38%) really is for the rigors of the return voyage. Other destinations are further away

still, and all those we can actually

land upon, are even lower gravity

than Mars. That situation says

quite clearly that we need to provide artificial gravity (no matter how

inconvenient that might otherwise be !!!!) at something near one gee

(until we actually know better !!) during these one-way transits

to-and-from, in order to best

preserve the health of the crews.

Ethically, you simply

cannot argue with that conclusion, no

matter how inconvenient for design purposes, or for total mission cost purposes. That is the only “box on thinking”

applied here.

Supplying

Artificial Gravity

There is as yet no such thing as “Star Trek”-type

artificial gravity. The only physics we

have to serve that purpose is “centrifugal force”. You must spin the vehicle, to generate “centrifugal force” as an

equivalent to gravity. If the spin rate

is low, then Coriolis forces (something

everyone has experienced on a merry-go-round) become less important, and so fewer folks can tell the difference

between this and real gravity, and

there are fewer problems with disrupting the balance organs in the ear.

The physics of spin say that the acceleration you feel is

proportional to the radius of spin and to the square of the spin rate. The actual physics equation says

a = R w2 where a is the acceleration, R the spin radius, and w the spin rate

Another form expressed in gees, and not absolute acceleration units, is

gees = 1.00

* [(R, m) / (55.89 m)] [(N, rpm) / (4 rpm)]2

Earthly experience with spin rates says that normal

untrained and unacclimatized people can tolerate 3 to 4 rpm immediately, and for long-term exposures, without getting motion sick. People extensively trained might (or might

not) tolerate higher spin rates in the 8-12 rpm class, without getting motion sick from long

exposures. Still-higher spin rates (16+

rpm) induce blood pressure gradients head-to-toe in a standing individual, that are just unacceptable for long term

exposures. Stand up, and you faint.

3-dimensional objects typically have 3 axes. About these axes these objects have properties

called “mass moment of inertia” that relates to spin dynamics. Usually,

higher moment of inertia correlates with a larger dimension along some

axis perpendicular to the actual spin axis.

These are typically proportional to mass, but proportional to the square of its

distance from the center of gravity.

There are two (and only two !!) stable spin modes for most

objects: about the axis for highest

moment of inertia (longest dimension),

and about the axis for lowest moment of inertia (shortest dimension). The first case is exemplified by a baton

twirler’s spinning baton, and the second

case is exemplified by a spinning bullet or artillery shell. There are no other stable modes of

spin. See Figure 1.

Figure 1 – Modes of Spin

Clearly, building a

“spinning rifle bullet” 112 m in diameter at 4 rpm for one full gee at its

outer girth is not so very feasible:

this is just too big to afford at this time in history. But spinning a smaller-diameter “something”

that is 112 m long, end-over-end at 4

rpm, for 1 gee at each end, would indeed be a feasible thing to attempt! That says select the baton-spin mode

for practical designs.

We already know a lot about the transient dynamics of

spinning rigid objects, something

important for spin-up and spin-down, as

well as for applying any thrust while spinning.

There would be no fundamental engineering development work to design a

long, narrow spacecraft that spins

end-over-end for artificial gravity.

There would only be proving-out the specific design in tests before we

use it.

The most-often-proposed alternative is a cable-connected

structure, because it is conceptually

easy to reel-out long cables between two small objects. Cable-connected transient dynamics for

spin-up and spin-down, and especially

for applying thrust while spinning, are

incredibly complex and still not very well-known. “You cannot push on a string”, that is the complication! So there is a huge fundamental engineering

development effort needed, beyond

just proving-out the actual design to be used.

What this really says is that the preferred near-term spacecraft

design is a long and rigid, more-or-less

cylindrical shape, to be spun

end-over-end, baton-style. This will generate varying artificial gee

from a maximum near the ends, to zero at

the spin center.

We know that microgravity vs gravity has no impact while

prone sleeping, or else Earthly bed rest

studies would not be a decent surrogate for some of the in-space microgravity

effects. That means you can put the

sleeping quarters in the low gravity section of the spacecraft near the spin

center, and just put the daily

workstations in the full-gravity sections of the spacecraft near the ends. See Figure 2.

Figure 2 – Why Selecting Baton Spin Mode Is Wisest Choice

Radiation

Hazards

There are basically three radiation hazards to worry

about: galactic cosmic rays (GCR), solar flare events (SFE), and the Van Allen radiation belts about the

Earth (or similar belts around some of the outer planets). All three hazards are atomic or subatomic particles, just at different speeds and quantities. The threats they pose are location-dependent.

GCR is a very slow drizzle of really-high-speed particles, moving at a large fraction of the speed of

light. Particles that energetic are very

difficult to shield against, because

they penetrate deeply into shielding material,

and quite often create “secondary showers” of other harmful radiation

when they strike the atoms in the shield material. If the shielding atoms are low atomic

weight, the secondary shower effect is

greatly reduced.

GCR comes from outside the solar system. Its quantity is affected by the solar

wind, in turn affected by the sun’s

sunspot cycle, which is about 11 years

long. The solar wind is stronger when

sunspots are active, making GCR lower in

the vicinity of the Earth-moon system at that time.

From NASA’s radiation effects website (ref. 1), I obtained these values that apply in the general

vicinity of the Earth-moon system. GCR

maximizes at about 60 REM per year when the sun is quiet, and minimizes at about 24 REM per year, when sunspots are most active. To “calibrate” the effects of what may be

unfamiliar units of radiation, the

natural Earthly background radiation is about 0.3 REM per year (and up to 10

times higher in some locations), and

a lethal dose would be 300 to 500 REM accumulated in a “short time”, meaning hours to a week or so. (Just for information, 1 Sievert is 100 REM.)

The NASA astronaut exposure standards are set at about twice

the levels allowed for Earthly nuclear workers.

Those NASA standards are no more than 50 REM per year, no more than 25 REM in any one month, and a career limit that varies with age and

gender, but maxes-out at no more than

400 REM accumulated over an entire career.

These career limits are predicated upon a single-handful percentage

increase in the likelihood of late-in-life cancer.

Clearly, with a

very modest shielding effect (to reduce worst-case 60 REM to an acceptable 50

REM annual), GCR is not the “killer” it

is often portrayed to be.

SFE (solar flare events) are different. They are much lower-speed particles, much easier to shield, but there is an incredibly-huge flood of

them, when these events happen. They come in very-directional bursts

from the sun, at rather erratic

intervals. There are usually

more of them during times of active sunspots,

but they can indeed happen when the sun is quiet. They come at irregular intervals measured in durations

of “several months apart”.

The intensity of a burst can vary wildly from only tens

of REM received over a few hours, to

tens of thousands of REM received over a few hours. The median dose would be multiple

thousands of REM over a few hours. Obviously, for unshielded persons, the great bulk of events like this (those

over about 300-500 REM) would be fatal doses,

and it is an ugly, irreversible, and miserable death. There was a massively-fatal-level event in

1972 between the last two Apollo missions to the moon, and a low-intensity (non-fatal) event during

one Apollo mission to the moon.

We had chosen to ignore this SFE threat during Apollo

because the short duration of the missions (at most 2 weeks) was small, compared to the typical interval (several

months) between events. But, had a large event hit during an Apollo

mission, the crew would have died in

space in a matter of hours. As it

turns out, this actual record shows that

Apollo’s “ignoring-the-risk-as-low-probability”-assumption was not a

good assumption to make! That’s 20-20

hindsight, but it is still a crucial

lesson to learn!

For an extended or permanent return to the moon, or going elsewhere, radiation shielding is obviously imperative! On Earth,

we are protected from these SFE’s (and the GCR) by both the Earth’s

magnetic field and its atmosphere. These

are a very real threat anywhere outside the Earth’s magnetic field! In low Earth orbit, we are protected only by the magnetic

field, and the background exposure there

is higher than down on Earth, but still much

less than beyond the magnetic field.

The Van Allen belts are concentrated regions of these same radiation

particles trapped in the Earth’s magnetic field. The intensity is lethal on a scale of days-to-weeks, but tolerable on a scale of hours-to-a-day-or-so. The inner boundary is not sharp, but this is generally considered to become a

problem at about 900 miles orbit altitude,

and extending many tens of thousands of miles out from the Earth.

The exception is the “South Atlantic Anomaly”, where the inner side of the Van Allen belt

dips down locally to low Earth orbit altitude (100-300 miles). Satellites and spacecraft in high-inclination

orbits inherently pass through the South Atlantic Anomaly every several orbits. The ISS does indeed encounter this threat, it being short “flashes” of exposure that accumulate

over time, but these still fall well within

the astronaut exposure standards (no more than 50 REM annually, no more than 25 REM in any one month). Their main effect is accumulation toward career

limits.

Spacecraft traveling to the moon or elsewhere must transit

the Van Allen belts. Because of the

potential for lethal exposure if you linger within them, such transits must be made quickly! Apollo did this correctly, transiting within only several hours. Given the state of today’s electric

propulsion technology, this rules out

using electric propulsion for people to leave Earth orbit for the moon or

elsewhere, because the spiral-out time

is measured in multiple months. That

would quickly accumulate to a lethal exposure,

even with some shielding.

Passive

Shielding

The same NASA radiation site has data regarding the

shielding effects of typically-considered materials. Those are hydrogen, water,

and aluminum. Mass of shielding

above a unit exposed area turns out to be the “correlating variable”, and 15-20 g/cm2 seems to be enough

to generally address the worst SFE.

Hydrogen has the lowest density, requiring the thickest layering, but also has the least secondary shower potential, when used against GCR. 211 to 282 cm of liquid hydrogen

suffices.

15-20 cm of water is 15-20 gm/cm2, same shielding effect as a really thick layer

of hydrogen. Water molecules are still light

enough not to have much secondary shower risk.

Aluminum would be the thinnest layer, but with the greater secondary shower

effect. However, of the practical metals, its atoms are the lightest, and this secondary shower effect is deemed

tolerable with it. 6-8 cm thick aluminum

plate would be required. That is

quite out-of-line with current spacecraft hull design practices: something nearer a millimeter.

Other materials based on polymers, and even most rocket propellants, are light-enough atoms to be effective shielding

with a low secondary shower risk, yet

with densities roughly in the same ballpark as water, for a thinner layer thickness. So,

any of these could be practical shielding materials!

Because weight is critical,

what you have to do is not simply add shielding weight to your

design, but instead rearrange the

distribution of masses you already otherwise need, so that they can also serve as radiation

shielding. You will need meteoroid

shielding and thermal insulation, and

any manned craft will have water and wastewater on board, as part of the life support system. All spacecraft will need propellant for the

next (and subsequent) burns. You

use a combination of these, acting

together.

The real suggestion here is to use water, wastewater,

and next-burn propellant tankage as shadow shields, in addition to the meteoroid protection and

thermal insulation materials that the manned modules require anyway. It doesn’t take much of this at all to cut

the worst-case 60 REM/year GCR to under 50 REM/year. It takes only a little more to cut worst-case

SFE to safe short-term exposure levels.

If you cannot protect the whole manned interior, then the flight control station becomes first

priority, so that maneuvers can be

flown, regardless of the solar weather. Second priority would be the sleeping quarters, to reduce round-the-clock GCR exposure

further. These seriously constrain

spacecraft design.

See

Figure 3 for one possible way to do this, in an orbit-to-orbit transport design concept. This would also be a baton-spin vehicle

for artificial gravity during the long transit. Plus, the

habitation (“hab”) design requires a lot of interior space for the mental

health of the crew, something else we

know is critical. Somewhere

between 100 and 200 cubic meters per person is needed as a minimum, and at least some of it must be

reconfigurable as desired by the crew.

Spin-up is likely by electrically-powered flywheels in the

center module. The vehicle is spun-up

after departure, and de-spun before

arrival. If a mid-course correction is

needed, the vehicle could be de-spun for

that, and spun back up for remainder of

the transit.

Note in the figure how the arrival propellant and the water

and wastewater tankage has been arranged around the manned core to provide

extra shadow shielding, for really

effective radiation protection. The

manned core modules are presumed insulated by polymeric layers that also serve

as meteor shielding (while adding to the radiation protection, without being driven by that issue). The pressure shell on the inside of this

insulation should be unobstructed by mounted equipment, so that easy and rapid access for patching of

holes is possible. There is not time to move stuff when a compartment is

depressurizing! Ethics!

At departure, the

vehicle can be propelled by a different propellant and engine choice, since departure is a short event. The arrival propellant is likely a storable

to prevent evaporation losses. Storable

return propellant tankage sets can be sent ahead unmanned, for docking in orbit at the destination.

There is an emergency return capsule (actually two capsules)

mounted at the center module, each one enough

for the entire crew. (“Bailout” at Mars

presumes a rescue capability already exists there, so we need redundant engines instead.) Emergency

bailout, upon a failed burn for returning

to Earth orbit, is the main function of

this capsule. Routinely, it could return a crew to Earth from the

spaceship, once it is parked safely in Earth

orbit.

This kind of orbit-to-orbit transport design could serve to

take men to Mars or to the near-Earth asteroids and comets. For Mars,

the lander craft could be sent ahead unmanned to Mars orbit, and none are needed to visit asteroids. But you cannot send return propellant ahead

on an asteroid mission.

By refueling and re-supplying in Earth orbit, such a manned hab design could easily be used

for multiple missions, once built. Care must be taken in its design and material

selection to support many thousands of cycles of use. Thus the craft could safely serve for a

century or more, updated with better

propellants and engines as the years go by.

There I went and wrote a basic “how-to” document for

practical and ethical interplanetary spaceship design!

Figure 3 – Using Otherwise-Required Materials To Also Serve

As Radiation Shielding

These first few sections so far have been reprised (with

edits) from “Just Mooning Around”,

posted 7-14-19. Everything that

follows is new.

Mars Mission Outline 2019: Overall

The new version uses a larger orbit-to-orbit transport, and recovers the solar-electric tugs that

preposition unmanned assets at Mars for the manned mission (2016 did not). It uses similar (but larger) landers as the

2016 version, and it still jettisons the

Earth departure stage without recovery.

That last could be addressed by fitting the departure stage with a

second propulsion system, possibly

electric, and putting it into a 2-year-period

orbit after stage-off. Then it could be

captured into Earth orbit for reuse. That

recovery possibility is beyond scope here in the 2019 version. Consider it to be a “future update”.

Main point here: if

one does spin gravity in a baton-spin mode,

the resulting transit vehicle is ill-adapted for a direct entry at

Mars, or a direct entry at Earth. Such a design is far better-adapted as an

orbit-to-orbit transport, with any Mars

lander function relegated to a separate vehicle, sent separately. Long-life reusability also points toward an

orbit-to-orbit transport design, free of

entry heat shield requirements. It

means we base our exploration forays onto the surface of Mars from low Mars

orbit.

The resulting mission architecture requires that both

the landers and the Earth return propellant get sent ahead unmanned to

parking orbit about Mars, with the

manned orbit-to-orbit transport arriving afterward, and rendezvousing in Mars orbit with those

items. This powerful concept is

not unlike the Lunar Orbit Rendezvous architecture that made it possible to

mount each Apollo landing mission with only one Saturn 5 booster. See Figure 4 for the overall mission architecture.

Figure 4 – Overall Mars Mission Architecture Requiring Mars

Orbit Rendezvous

The landers themselves are envisioned as one-stage

reusable articles that make multiple flights, based out of low Mars orbit. Sending 3 landers ahead with their propellant

supply allows one lander to make a landing with only part of the human crew, with a second lander in reserve as a rescue

craft. Thus, there is a “way out” even during the

landings, unlike with Apollo!

Because of storability concerns, the wisest choice is that the lander

propellant and engine design be the same as the transport propellant and

engine design. This maximizes the

interchangeability of engine hardware and propellant supplies, in the event that there are mishaps from

which to recover, without aid from

Earth. It also simplifies the overall

design and hardware development and prove-out.

The presence of a third lander allows one lander to become

unserviceable, while still

maintaining the reserve rescue lander capability, without which landings so far from Earth

become too risky to ethically attempt.

This is shown in Figure

5, including the velocity

requirements for the lander design.

The initially-sized version of the lander design concept was

used in the 2016 posting, and came from

one of the options explored in another posting titled “Reusable Chemical Mars

Landing Boats Are Feasible”, dated 31

August 2013. These landers are resized

somewhat for this posting.

Figure 5 – Surface Landing Forays Based Out Of Low Mars

Orbit

Note that for a rescue possibility to exist, some of the crew must stay in the transport

in low Mars orbit, while others descend

to the surface in a lander.

Because we do not know how therapeutic Mars’s 0.38 gee gravity might be

for the surface crew, I suggest we spin

the transport for artificial gravity while it is in orbit, de-spinning for lander departures and

arrivals. Thus everybody stays fully

healthy no matter what, while we

alternate crews on the surface.

Now, overall, it is worst-case 9 months to and from

Mars, and in any case, 13 months at Mars waiting for the orbital

“window” to open for the voyage home. That

last is simply inherent from the choice of min-energy Hohmann transfer orbits. That leaves a long time for the crew to

explore on Mars. That plus the

possibility that the initial landing site might not prove to be desirable, makes it wise to plan for multiple

landings, at possibly-multiple

sites.

Basing exploration forays from low Mars orbit is

what makes multiple landings at multiple sites possible at all! No other mission architecture can

provide this capability.

It is that orbit-based architecture allowing for multiple

landings which lets us alternate roles for the crew, so that all of them get to spend time on

the surface of Mars (unlike what was possible with Apollo). With a mission crew of 6, that means we could send down alternating

crews of 3 in the lander, while the

other 3 do science from orbit and provide the critical watchdog rescue

capability with the other two landers (two for the reliability of

redundancy). It is already known that

odd numbered crews fare better in hazardous situations, there being no possibility of the stalemate

of ties, in decision-making.

Given the existence of the rescue capability from low Mars

orbit, we can address lander reliability

in two ways, thus increasing the odds of

success, and also the odds of still saving

the lander crew, if things go seriously

wrong. (We are ethically bound to do this!) First,

the lander must use redundant engines,

so that if one fails, the

remaining engine (or engines) can still perform the mission.

Second,

the crew piloting cabin could be rigged as an abort-to-surface (or

abort-to-orbit) capsule, in the event

that too many redundant engines fail, or

that there is some overall catastrophic failure of the lander.

The minimum number of landings is two, one for each half of the crew. Allowing some time for

reconnaissance-from-orbit prior to the first attempt, and for preparations for returning to

earth, we can plan on 12 months total

for the landings, splitting the

remaining month between those other two needs in orbit about Mars. That does cover up to two possible landing

sites in the one voyage to Mars!

The surface crew will live inside the lander on the

surface. That means it must carry

them, their exploration gear, and up to 6 months of life support supplies, on each trip.

More exploration gear could be carried to the surface if we shorten the

stay for each lander.

If four trips will be made,

that’s 3 months each (not 6), and

one can trade away life support supplies for extra exploration gear carried

down. That could cover up to four

possible landing sites in the one trip to Mars,

and each crew of 3 making 2 trips,

all with the same overall resources sent to Mars, excepting the total lander propellant supply.

Continuing that logic,

if 6 trips are planned, that’s 2

months each, each crew of 3 making 3

trips, and a higher weight of

exploration gear relative to life support supplies. That’s up to 6 separate sites that could be

explored in the one voyage to Mars! Or, 12 trips of 1 month each, which is up to 12 sites explored. Since the lander propellant is sent ahead by

SEP, it is rather easy to afford such a capability.

The biggest mass ratio-effective burn for the lander is the

ascent burn, which can be at

significantly-reduced payload, since

wastes can be left on the surface along with some exploration gear, while the weight of a plethora of samples is

far less than the weight of gear and supplies during the less-demanding

descent. That makes the overall 5.22

km/s delta vee far more affordable with an overall realistic mass ratio and

storable propellant specific impulse (Isp).

Those considerations very dramatically impact and constrain

the design of the lander.

Sending Assets Ahead Unmanned

The unmanned transfers can be done more efficiently (lower

total mass to be launched) with solar electric propulsion (SEP). The manned transport uses short-burn chemical

rocket propulsion to avoid long spiral-out/spiral-in times. (An SEP-based transport would give the crew a

lethal radiation dose spiraling-out through the Van Allen belts on departure

from Earth, and again spiraling-in

through the belts on return to Earth.) At

least approximately 0.1 gee vehicle acceleration is required to qualify as a gravity

loss-free “short burn”.

This prepositioning of assets at Mars using SEP was also a

part of my 2016 Mars mission posting. The

differences here are that I recover the SEP “tugs” for reuse on future missions, and that I use a larger “hab” for the orbit-to-orbit

transport.

Earth Departure of Manned Transport

The Earth departure can be done with higher-performing

LOX-LH2 tankage and engines on one end, that are staged off after the burn. To recover these, a higher aphelion orbit with a 2 year period

is required, plus some sort of

propulsion to return to Earth orbit. This

could be electric, or some storable

propellant rockets. (Expecting LOX-LH2

cryogens not to evaporate over a 2 year period is just nonsense!) I did not include that here, but it is required for more reusability. That’s a future growth item.

Velocity Requirements for the Mission

The orbital mechanics of min-energy Hohmann transfer

determine the minimum velocity requirements for the manned (and unmanned) vehicles, as well as the one-way travel time. Shorter flights require more energy, which is more propellant and tankage that

must be sent to low Earth orbit and assembled.

The basic velocity requirements for the manned orbital

transport are shown in Figure

6. These take the form of

unfactored orbital mechanics values serving as the mass ratio-effective values

for vehicle design. This is allowable

because all these chemical rocket propulsion burns are “short” and

exoatmospheric. The resulting mass-ratio-effective

design values are given in Figure

7.

Figure 6 – Orbital Velocity Requirements For The

Orbit-to-Orbit Manned Transport

For only Mars arrival with the manned transport, there is a need for a rendezvous propellant

allowance. It is necessary to adjust

orbital position to coincide with the assets sent ahead. As a wild guess, add another 0.2 km/s delta vee to the value

shown in Figure 7 as the mass ratio-effective value for design.

Figure 7 – Design Velocity Requirements For The

Orbit-To-Orbit Manned Transport

For the assets sent ahead with SEP, design velocity requirements are much more

problematic. There are no drag

losses, but the gravity losses are

huge, since the burns are months long! For a rough rule-of-thumb estimate, just use twice the values in Figure 7. That is what I did here.

Propulsion Estimates

No particular existing chemical rocket engine’s

characteristics were used. Ballistic

estimates were made “from scratch” using shortcut methods. For both the transport and Earth-departure

engines, it was assumed that no

gas used to drive pumps was dumped overboard,

meaning 100% of the hot gas generated went through the propulsion nozzle. This requires an efficient engine operating

cycle.

Estimates were made from 1000-psia data for chamber

characteristic velocity and gas specific heat ratio, using standard ideal-gas compressible flow

methods to develop vacuum thrust coefficient (to include the effects of a

nozzle kinetic energy efficiency reflecting streamline divergence). The c* and r “constants” vary with chamber

pressure in a way that conforms to empirical ballistic methods I have long used

successfully.

This gets us to specific impulse (and thus effective exhaust

velocity) for vehicle mass ratio determinations with the rocket equation dV =

Vex ln(Wig/Wbo). The actual design

thrust level is driven by vehicle mass and the min 0.1 gee acceleration

requirement, which sizes throat (and

exit areas) via the thrust/throat area/thrust coefficient equation F = CF

Pc At. That leads to real engine

dimensions. For

not-quite-the-highest-tech in engine design technology, a good “wild guess” for engine weight would

be thrust/50, both in force units, figured at 1 gee Earth gravity for the weight.

Assuming redundant engines for safety and reliability, these rockets won’t be simultaneously run at

full thrust. For vacuum-only

operation, there is no need for really

high chamber pressure, and there is no

need to worry about backpressure-induced separation effects, because there isn’t any backpressure. 6-7 mbar on Mars is also effectively no

backpressure at all, so the lander

engines can be the same vacuum design as the transport engines.

Reflecting those considerations, I assumed 1000 psia at max thrust, typical operation at 500 psia, and min throttled-down pressure 200 psia. Others may disagree, but that is what I did. The higher the Pc, the higher the c*, and thus the higher the Isp. But so also the higher is the weight of the

engine.

The data I got for the NTO-MMH storable transit engines are

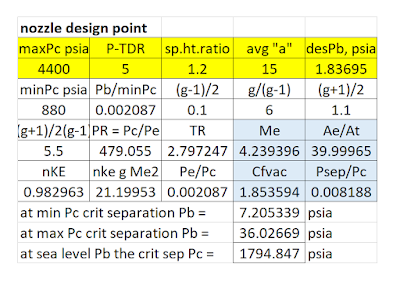

given in Figure 8. The data I got for the LOX-LH2 Earth

departure engines are given in Figure 9. For both I

assumed an expansion bell equivalent to a constant 15 degree half-angle conical

bell, leading to a kinetic energy

efficiency of 0.983 for the nozzle efficiency.

Any real-world curved bell will have an average half angle not far at

all from that value; it will be slightly

shorter than the equivalent conical bell,

and just about the same efficiency.

Figure 8 – Ballistic Estimates For Storable-Propellant

Transit (and Lander) Engines

Figure 9 -- Ballistic Estimates For Cryo-Propellant Earth

Departure Engines

The solar electric propulsion is more problematical in its

characteristics, it being currently available

only in small sizes, with scaleup

efforts underway at both Ad Astra and NASA.

What is important for vehicle design purposes would be thrust/weight for

the actual electric thruster equipment,

its operating specific impulse,

its electric power/thrust requirement,

and the type and phase of its propellant (liquids or solids are easier

to store at lower total tankage weight than gases).

Add to that the producible electric power/panel area, the weight/panel area, and miscellaneous equipment weight (if

any), for the solar power supply

equipment, and for autonomous robotic

vehicle guidance. The size of the

thruster’s thrust relative to the full vehicle weight should probably fall near

what the current small thrusters on satellites use: something near or above 0.001 gee.

Here are the values for the putative system I “chose”, it being something that does not yet exist, but likely could be made to exist near-term. Bear in mind the available solar power at Mars

is half that at Earth (Mars actually sizes the panels). The value shown for electric power/area of

solar panel is for near-Earth space,

turned to face the sun directly. This data represents a Hall-effect device

on iodine.

SEP Items Data Table

The solar photovoltaic power per unit area was estimated as

the solar constant at Earth (in space 1353 W/m2) multiplied by a 20%

conversion efficiency of sunlight power to electric power. That represents a

high-tech space-industry type of solar cell.

The weight was estimated from reported data for the Alta Devices Alta

5x1 2J and Alta 5x1 1J satellite solar panel devices. The miscellaneous equipment is not

structure, that is in the weight/area

figure for the panels. It is the mass of

the autonomous guidance equipment,

including things like star trackers,

computers, communications, and accelerometers.

Space Hab for the Crew:

Characteristics

I based these guesses off the Bigelow Aerospace B-330 space

station module design as seen on the internet (ref. 2).

This is the big commercial product,

not the simple, small BEAM unit

attached to ISS for testing and evaluation by NASA. These are nominally 15.7 m long and 20 metric

tons. They are somewhat inflatable, and feature a core equipment and framing structure

around which the inflated hull is unobstructed. There is a meter of layers of micrometeoroid

shield that also serve as thermal insulation,

and as low-molecular-weight radiation shielding. Each module contains some 330 cubic meters

of interior space. The hard core protrudes on one end, providing a place for solar panels.

The modules of the orbit-to-orbit transport cannot be

exactly these B-330 modules, but can

be something rather similar! Docking

multiple modules end-to-end creates the baton-shaped vehicle this mission

design needs. The modules must have

external features of some type that allow tankage to be attached around the

outer periphery, and internal fold-out

decks as part of the core. The center

module must be very stout, and contain

big electrically-driven flywheels for vehicle spin-up and spin-down, plus places to dock space capsules.

It would seem wiser to put big solar panels on the center

module, with the docked capsules, and the flywheels inside, where spin forces are zero-to-minimal. It is likely to be hard shell, not an inflatable, for strength.

That module is also likely to be quite heavy. As a wild guess, call it 16 m long and 40 tons. The others can be nominal 16 m long, and nearer 20 tons, reflecting inflatable pressure shell along almost

the entire length, plus the features for

attaching external tankage. Call the

internal volume 350 m3 each as a best guess, excluding what the hard core occupies.

Counting the center module,

some 7 modules each 16 m long docked end-to-end is 112 m long, for 1 full gee at each end if spun at only 4

rpm. That basic structure would total 160

metric tons, using the guesses in

the previous paragraph. To that one must

add masses for crew and 2 space suits each,

their personal effects, and personal

equipment (call it 0.5 metric ton per person as a guess), and for fully-expendable supplies of

food, water, and oxygen (call it 0.75 metric tons per

person per month, knowing that these are

just “reasonable guesses”). Crew and

supplies must fit within the vehicle,

which has (for the 6 modules not filled with flywheels and heavy

equipment) some 2100 m3 volume.

If one assumes half the volume is packed supplies, and also a crew of 6, that leaves some 175 m3 per person

as living space available. That’s about

like 3 large living rooms in a typical middle-class house. That seems adequate at first glance, if it is well distributed, and some part of it is reconfigurable at some

level.

The crew weight allowance is 3 metric tons, and the packed supplies mass is about 4.5

tons per mission month. If the mission

is 31 months long (9 months transit, 13

months at Mars, 9 months return), that’s about 140 tons of supplies, with no margin for error. So call it a nominal 150 tons. This presumes no recycling or growing-of-food

in space or on Mars. It’s a worst-case

deal, but we can do this “right

now”.

So, the empty hab

section is estimated at 160 tons. It

gets loaded with about 150 tons of supplies,

allowing for 7.5% safety factor on supply mass, and loaded with about 3 tons of crew with

their suits, equipment, and personal effects. Fully loaded,

that’s 313 tons. That would be

crew of 6, and supplies for a 31 month

mission plus a small margin. See Figure 10. Figure 11 shows an image of the spreadsheet where these numbers

were calculated. Yellow highlighting

denotes inputs. Some selected outputs

are highlighted blue.

Figure 10 – The Estimates for the Hab Section Structure of

the Orbit-to-Orbit Transport

Figure 11 – Image of Spreadsheet Used to Determine Hab

Section Characteristics

Assumed depleted at a constant rate, the supplies total 150 tons at

departure, 109.5 tons at Mars

arrival, 51.0 tons at Mars

departure, and not-zero at 10.5 tons at

Earth arrival, assuming the safety

margin is not consumed. This presumes

wastes are dumped overboard with no recycling at all! This dumping reduces the effective mass of

the hab section, at each mission segment, a benefit to propellant required.

We can already do somewhat better than that with recycled water, but this is a worst case estimate! Yet this open-cycle assumption gets the smaller

propellant supply for return to Earth.

“Efficiency” is not always beneficial: that is too often presumed erroneously! Jettisoned mass reduces next-burn propellant

requirements. That’s just physics you

cannot fight!

Sizing the Manned Transport and Its Return Propellant

The fundamental notion for sizing propellant supplies for

the four events (Earth departure, Mars

arrival, Mars departure, and Earth arrival) is that the mass of the

loaded, crewed hab, plus the mass of all propellant tankage, plus the mass of the engines, is the ignition mass. That minus the mass of propellant burned from

that tankage is the burnout mass. That

produces a mass ratio for the burn, and

the delta-vee it will produce, which

must meet or exceed the requirement for that burn. This is subject to the constraint that we

want 0.1 gee or thereabouts as a min vehicle acceleration at each burn.

To do this, one must

estimate the ratio of propellant to loaded tank mass for the added

tankage. This has to reflect a

long, slim tank geometry for docking

multiple tanks around the periphery of the hab,

and it must account for the mass of the docking structures needed to

achieve that result. As a guess, I am assuming that the empty tank inert mass

(with all those fittings) is 5% of the loaded tank mass, so that the contained propellant is 95% of

the loaded tank mass.

To that end, I used a

series of calculation blocks in a spreadsheet worksheet to run the

calculations. Again, inputs are highlighted yellow, and significant outputs are highlighted

blue. Figures 12,

13, and 14 show the results.

Bear in mind that the loaded tank mass for the Mars and

Earth arrival burns must be part of the “payload” for the Earth and Mars

departure burns, respectively. They are unique in this way. That means the dead-head payload is the

appropriate hab mass plus the mass of the next burn’s loaded tanks. The current burn’s tanks must push this (plus

the added engine mass) to the required delta-vee for that burn.

Added engine mass is handled by an iteratively-applied

tankage scale-up factor just slightly over unity.

Figure 12 – Part 1 of Orbital Transport Propulsion Sizing

As it turns out,

finding the propellant tankage mass to push the hab to the required

delta-vee is not an excruciating iterative process. You first find the mass ratio MR that is

required from the required mass ratio-effective delta-vee, and the propulsion’s effective exhaust

velocity, by the rocket equation. Ignoring the mass of the engines

themselves, it turns out to be closed-form

to find the loaded tankage mass Wtf from that mass ratio, and the total “dead head” mass to be pushed in

that burn.

For both departures,

the “dead head” mass is the appropriate loaded hab mass plus the loaded

mass of the corresponding arrival tankage.

For both arrivals, the “dead

head” mass is just the loaded hab mass.

This can be corrected at the 1 or 2% level for total engine mass

later, to ensure fully meeting the

delta-vee requirements, simply by

scaling up the loaded tank mass Wtf with a factor applied iteratively until

delta-vee produced meets the requirement.

Wtf =

Wdead (MR – 1)/(1 – MR f) where f =

Wt/Wtf and Wt is dry tank mass

Figure 13 – Part 2 of Orbital Transport Propulsion Sizing

Figure 14 – Part 3 of Orbital Transport Propulsion Sizing

That’s the orbital transport rough-out design for Mars. It can get there to low Mars orbit from low

Earth orbit where it was assembled. It

can rendezvous with its Earth return propellant, the Mars landers, and the Mars lander propellant supply, all three of which were sent ahead by

electric propulsion. The nonrecoverable

items are the Earth departure stage and the empty Mars departure tanks. The empty Mars arrival tanks are left in Mars

orbit. Everything else about this design

is recovered in low Earth orbit.

Note that this ship is 1413 metric tons, as assembled and loaded in low Earth

orbit, ready to go to low Mars orbit. Its use requires that some 997.26 metric tons

of loaded propellant tanks be sent ahead to Mars for the return propellant

supply. In order to actually make

landings on Mars as staged out of low Mars orbit, the landers and their propellant supply must

also be sent ahead to low Mars orbit.

With much bigger propellant tankage, this same design could take men to a

near-Earth asteroid. For such

missions, landers are not needed, and there is no practical opportunity to

pre-position return propellant, except many

years ahead. Those missions are far

more difficult. Analysis of one is not

attempted in this posting.

Sizing the Lander and Lander Propellant Supply

The lander payload is its crew, their suits and personal equipment, plus an amount of life support supplies that

depends upon how long the crew will live in the lander on the surface, each landing.

The de-orbit burn for a surface-grazing ellipse is a trivial 50 m/s

delta-vee. Most of the deceleration is

aerodynamic drag, effectively terminating

at end-of-hypersonics at Mach 3, just

about 1 km/s velocity, but at a low

altitude because of the high ballistic coefficient. That altitude is only about 5 km!

From there,

deceleration is by retropropulsion alone, with a large “kitty” to cover hover and

divert requirements. Assuming 1 km/s

velocity at 5 km altitude, along a

straight slant trajectory at 45 degrees,

the average deceleration level required is 70 m/s2, or 7.211 gees, which with the lander mass, sets the required engine thrust level for

landing. That is a rough ride, about twice the rigors of return from low

Earth orbit, and justifying all

by itself the maintenance of full crew health with artificial spin gravity!

The lander is a one-stage reusable “landing boat” intended

to make multiple flights, each fueled

from a propellant supply sent with it to low Mars orbit. Factored,

the mass ratio-effective descent delta-vee is just about 1.5 km/s. Propellant is storable NTO-MMH, to preclude evaporation losses and massive energy

requirements to prevent freezing or boiling.

The ascent must account for small but non-zero gravity and drag losses

(about 2% of velocity), and a “kitty”

for rendezvous maneuvers. That mass-ratio-effective

delta vee is just about 3.62 km/s.

The payload requirements for crew, equipment,

and supplies as a function of surface duration are given in Figure 15, along with a crude estimate of the “larger-than-minimum”

vehicle inert weight fraction that is appropriate to the necessary structural robustness,

and to the equipment required to

function as a reusable entry-capable vehicle,

and as a surface habitat.

Conceptually, the lander is

sketched in Figure 16. Some of its backshell panels double as cargo

load/unload ramps. Most of the cargo

space can be isolated and pressurized as living space, once unloaded. The piloting cabin is the abort capsule, something somewhat similar to a crew Dragon

from Spacex. This thing is NOT a

minimalist lander the way the Apollo LM was.

Figure 15 – Payload Requirements Vs. Surface Duration

Figure 16 – Conceptual Sketch of Reusable “Landing Boat”

The ascent payload is smaller, since most (but not all) the supplies are

used up (and wastes left behind) at ascent liftoff. There is a generous allowance for Mars

samples to be returned to the orbital transport. This has to be taken into

account in calculating the actual vehicle masses, since the two delta-vees are handled at two

different payload fractions, in the one

vehicle design. That process is

inherently iterative, as shown by the

data given in Figure 17.

Figure 17 – Iterative Determination of Lander

Characteristics vs Surface Duration

In order to determine these numbers, one guess a value for the max lander

mass, which is ignition-at-descent (Wig-des). The inert fraction times this gives the

vehicle inert mass Win. The ascent and

descent payloads are determined vs mission surface duration separately. The mass ratios already determined are used

to estimate propellant masses.

The ascent propellant mass Wp-asc is determined first as

(MR-asc – 1)(Wpay-asc + Win), then the

descent propellant mass Wp-des as (MR-des – 1)(Wpay-des + Win + Wp-asc), treating the ascent propellant as part of the

effective “payload” during descent. The

descent payload plus both propellant masses plus inert mass sum to the result

for descent ignition mass.

The input guess for descent ignition mass is then adjusted

iteratively, until it converges to

the result for descent ignition mass.

This is done by simple trial and error in the spreadsheet. There is such a result computed for each of 4

possible surface durations that divide evenly into the 12 months

available. These results are then the

inputs for a characterization of the lander sizing as a function of design

surface duration.

For the selected 2-month duration (corresponding to 6

total lander flights), those results

are given in Figure 18. These show ascent and descent weight

statements, confirmation of delta-vee

capability, and characterization of

vehicle mass fractions, plus the

propellant supply required to cover the appropriate number of flights. Similar tables exist in the spreadsheet for

the other 3 durations, but those are not

shown here.

Figure 18 – Lander Design Characteristics for 6 Flights of 2

Month Surface Duration Each

Figures

19 and 20 show the trade-off of vehicle sizes and propellant supply

sizes versus surface duration options. The

selected design is near the “knee” in the curve of number-of-flights vs surface

duration, at 2 month duration for 6

flights. For shorter duration, the required propellant supply is

significantly larger. For longer

duration, the required propellant supply

is smaller, but not so significantly

smaller.

The lander size itself is significantly affected by the

design surface duration, being larger at

longer duration. The 2-month duration

selected limits this affect, without so

significantly penalizing the payload fraction (which ranges from about 2 to

about 3%). The selected 2-month duration

is also near the “knee” in that curve.

Longer durations do not improve this as much as was gained going from 1

month-12 flights to the selected 2 month-6 flights option.

Figure 19 – Number of Landings and Required Propellant

Supply Vs. Surface Duration

Figure 20 – Lander Size and Payload Fraction Vs. Surface

Duration

For this selected design (6 two-month surface stays), three landers fueled and loaded with

supplies, less crew, suits,

and personal equipment, each

massing 376.5 metric tons, must be sent

to Mars along with some 1764 tons of propellant to support all 6 flights. If 95% of the tank weight is propellant, the mass of loaded tankage to be sent is some

1856.8 metric tons. If sent as tanks

docked to each of the 3 landers, that’s

a 376.5 ton lander plus 619 tons of loaded propellant tanks.

The “smart” thing to do from a reliability /

self-rescue standpoint is to send the transport return propellant with those

same three landers, so that if one is

lost, the transport can still return

safely by drawing the shortfall instead from the remaining lander supplies. That return propellant was determined above

to be 997.26 metric tons of loaded tanks.

Divided by 3, that’s an

additional 332.4 metric tons of Earth return propellant tankage sent to Mars

with each lander.

That makes each lander plus propellant tanks a 1327.9

metric ton item to be moved by solar electric propulsion from low Earth orbit

one-way to low Mars orbit. Each

such is thus quite comparable to the departure mass of the manned orbital

transport. That would not be true

at the other surface durations.

There are 6 landings to be made, and three such landers sent to Mars. Distributed evenly, that is two flights per lander minimum, and 6 maximum. Bear in mind that only one lander is sent to

the surface at a time, carrying a crew

of 3, while the other three crew do

science in orbit, while acting as the

safety rescue “watchdog”, with at least

one functional lander, even if the other

one fails. The worst case is that all 6

flights are made with one lander. Thus

the lander design must allow for at least 6 flights per vehicle, justifying in part the higher inert mass

fraction used in this design rough-out.

Landers get left in low Mars orbit at mission’s end, when the transport departs for Earth. Subsequent missions might utilize these

assets, and reduce the sent mass to only

more lander propellant. That

possibility argues for much more than 6 flights per vehicle, in turn a really good argument for the very

robust inert mass fraction of 20% used here. Alternatively, they could be landed robotically.

Common Engine Design for Transport and Lander?

The lander mass is 378 metric tons at ignition, and 241 at touchdown, as just determined above. The average is 309.5 metric tons. Also as determined above, the average deceleration required is 70 m/s2. That translates to 21,665 KN of

retropropulsion thrust required to safely land (nominally 22,000 KN). This is totaled for multiple engines. Less may be used for ascent, as such high gee capability is not required

for that. Something nearer 2 gees at ascent

ignition mass 236.3 metric tons (4726 KN thrust) is more appropriate.

As described above,

something near 1170 KN thrust from multiple engines is the minimum

required for the orbit-to-orbit transport.

This was set by the min 0.1

vehicle gee capability at max vehicle mass,

and still resulted in only large fractional gee capability at min

vehicle mass. This thrust level

selection could be doubled or tripled (or more) with relative impunity.

A worksheet page was set up in the spreadsheet to explore

how this could be done, in two

steps. The results are shown in Figure 21, which indicate the possibility of using some

number of 3600 KN max thrust engines,

throttleable from 20 to 100%. In

the first step, I input factored thrust

requirements, plus a number of

engines, and a max number of inoperative

engines.

The thrust requirement for the lander descent is based on

slowing the average descent mass (as a constant) from 1 km/s to zero, in a slant path length of 7.1 km, using the oversimplified kinematic equation V2

= 2 a s. This is a very high-gee

descent! Reducing that requires

not just supersonic retropropulsion, but

hypersonic retropropulsion (starting retropropulsion earlier in the entry

sequence). It is an inevitable

consequence of the high ballistic coefficient producing very low altitudes (on

Mars) for end-of-hypersonic deceleration.

This is an area for further design work!

The thrust requirement for the lander ascent is its Earth

weight, factored-up just slightly, to accommodate flight tests on Earth. That’s “overkill” for Mars with its lower

gravity.

The thrust requirement for the orbital transport is based on

its Mars departure mass (largest of the masses under storable propulsion) and a

min 0.1 gee vehicle acceleration requirement.

This is arbitrarily factored-up by 3 to achieve commonality, without exceeding max gees ~ 2 at Earth

arrival.

That initial result indicated that something like 3600

KN max thrust per engine would be suitable, with 9 engines in the lander operating at

part throttle in descent, and 4 engines

operating at part throttle in ascent,

able to lose up to 3 engines either way,

and still function within limits.

This was explored further,

looking at vehicle gees and engine throttle percentages, in the second step.

Up to 3 of these lander engines could cease operation during

ascent or descent. The remainder could

supply adequate thrust at 100% throttle or less, without waiting for lightoff of any

inactive engines. That’s an important safety consideration, which ethics demands! Two of these same engines would be adequate

to push the orbital transport at part throttle,

with only one operating engine still able to supply much more than the

demanded minimum thrust.

Figure 21 – Determination of Size and Distribution of a

Common NTO-MMH Engine Design

In all cases, engines

operate between 20 and 100% throttle setting,

and appropriate gee limits are not exceeded. Min transport vehicle gee requirement (0.1

gee) is exceeded.

For descent, the

lander retropulsion operates between about 6 and about 9 gees. This event is only about 14-15 seconds

long!!! “At the last second” to

actually land, some 8 of the 9 engines must

be shut down to reduce thrust to nearer Mars weight of the lander (about 749 KN

to 872 KN, depending upon how much

propellant was burned) at touchdown,

with the remaining active engine operating at about 21-24% thrust

setting. This single-engine point is the

riskiest aspect of the landing, but it

is mitigated by the facts that (1) this engine is already operating, and (2) it need only continue to operate at

reduced thrust for a second or two.

On ascent with a reduced number of engines, this is 1.2 to 3.6 gees for the lander at

full thrust, far more than is needed to

depart against Mars gravity (only 0.38 gee).

Active throttling reduces that some.

The transport operates between 0.3 and 1.8 gees during the

return to Earth. This exceeds the min

acceleration requirement, but not the

maximum. A 3600 KN engine design for

this NTO-MMH common engine would resemble the notional sketch in Figure 22.

If the Earth departure stage at 1350 KN uses 5 engines, each would be approximately 1350 KN max

thrust capability operating at 20% thrust.

Up to 4 could be non-functional,

and still easily meet the overall min departure thrust requirement, without exceeding 100% throttle. Higher vehicle acceleration than 0.1 gee is

easily obtained, but even with all 5

engines at full thrust, it is still only

fractional gee. Such a 1350 KN LOX-LH2

engine would resemble the notional sketch in Figure 23.

Figure 22 – Sketch of Proposed 3600 KN NTO-MMH Common Engine

(one of 2 transport, 9 lander)

Figure 23 – Sketch of Proposed 1350 KN LOX-LH2 Earth

Departure Engine (one of 5 on the departure stage)

Sizing the SEP for the Unmanned Assets Sent Ahead

This item is the most speculative, because (1) it uses the most assumed

data, and (2) this kind of solar

electric propulsion has yet to be scaled up to such sizes to push masses this

large. To cover the gravity losses (both

planetary and solar), I simply doubled

the required orbital delta-vee data.

I simply assumed the average characteristics of small Hall

effect thrusters operating on iodine could be scaled way up by simple

clustering, at the same thrust/weight

and thrust/power ratios. And, I just assumed the characteristics of

satellite-sized solar panels could be scaled up to the low-hundred kilowatt

range at the same power/area and weight/area ratios.

My approach was a self-contained solar-electric propulsion

(SEP) “tug”, that incorporates the

clustered thruster unit, the solar

panels to power it, sized for reduced

sunlight at Mars, a robot guidance

package, and a low-pressure “tank” to

contain the easily-sublimated and

inexpensive iodine propellant. I used

published data for two Busek Hall-effect thrusters, and for a couple of Alta Devices satellite

solar panels, for these estimates.

This SEP “tug” is coupled to a dead-head payload for the

trip from Earth orbit to Mars orbit,

using all of its 120 clustered SEP thrusters to achieve a milli-gee of

vehicle acceleration capability at Earth departure. That payload is one (of the three) Mars

landers (fully fueled and supplied),

plus a 1/3 share of the total lander propellant supply, and plus a 1/3 share of the manned orbital

transport’s Earth return propellant supply.

This dead head payload is over 1300 metric tons.

For the return trip (these “tugs” are fully reusable), there is no dead-head payload, only the “tug” and its iodine tank, still containing just enough iodine

propellant to get home. During the trip

home, only one SEP thruster in the

cluster need be used to achieve near a milli-gee of vehicle acceleration at

Mars departure. That leaves many “spares

in case the one fails”, insuring utter reliability. (Outbound,

the cluster is large enough that the loss of a few thrusters is no significant

percentage loss of thrust.)

The size of one such thruster (200 mN, mN meaning milli-Newtons) falls within the

range of thrusters produced today. This

produces adequate acceleration of the unladen vehicle. The scaleup is by clustering, not by increasing the size of the thrust in

such a device. The clustering-together

of 120 of these units produces some 24,000 mN,

needed to move the laden vehicle at adequate acceleration.

The resulting SEP “tug” design is depicted in the sketch of Figure 24. I used a big two-stage spreadsheet worksheet

to iteratively size this “tug” system,

examining the 4 “burns” individually.

The second stage of this process fully defines the characteristics of

the “tug” and its estimated performance.

This is the tabular data in the partial spreadsheet image shown in Figure 25.

Hopefully, this

rough-sizing is “overkill”, due to my just-assumed

doubling of the orbital delta-vee requirements.

The intent here is to slowly spiral-out of low Earth orbit to

escape, and continue an accelerating

spiral about the sun to an appropriate midpoint, then use a decelerating spiral about the sun

toward capture at Mars. From there, it follows a decelerating spiral-in to low

Mars orbit. The return uses the same

spiraling processes, just unladen of

dead-head payload, and at far-lower

thrust and propellant requirements.

Figure 24 – Depiction of the SEP “Tug” Design Sizing

Rough-Out

Figure 25 – Partial Spreadsheet Image Showing “Tug”

Characteristics and Performance

Sizing the Earth Departure Stage

Of all the items analyzed,

this is the easiest and most straightforward, because there is one and only one burn (the

Earth departure burn). Then this stage

is jettisoned. The stage layout concept

and sized data were already determined as part of the orbital transport

propulsion sizing above. These data were

given as part of Figures 12, 13, and 14 above,

plus part of the common engine discussion just above, with sized engine dimensions in Figure 23.

Just to summarize,

the departure stage has 5 LOX-LH2 engines each designed for 1350 KN

thrust, weighing an estimated total of

5.139 metric tons. The stage comprises

LOX and LH2 tankage whose combined dry weight is 41.906 metric tons. The total propellant load is some 796.210

metric tons. Thus the loaded stage

itself is some 843.255 metric tons.

This stage pushes a fully loaded and crewed hab plus Mars

arrival propellant tankage that totals some 569.810 metric tons of dead-head

payload. Total orbital transport vehicle

mass, at Earth departure ignition, is thus some 1413.065 metric tons. This was shown in Figure 14 above, including weight statements and performance.

Not considered here is reuse of the Earth departure

stage. Its engine sizing would be

fine, but it needs larger tanks and

propellant to accomplish 2 burns. The

first is to put the orbital transport onto a Hohmann transfer ellipse

trajectory.

After releasing the transport, it burns a second time to enter an ellipse

about the sun with an exactly two-year period.

That way the Earth is there when it reaches perihelion, thus making recovery feasible at all.

It is just not reasonable to expect that cryogens like LOX

and especially LH2 will not completely evaporate away over a 2 year

interval. Therefore, the reusable form of the stage must also

incorporate a second propulsion system storable over long periods. This added propulsion provides the delta-vee

to return to Earth orbit from the 2-year solar orbit perihelion conditions.

Being unmanned, there

is no reason this second propulsion system could not be solar-electric using

iodine. The stage then executes a

spiral-in to low Earth orbit after capture.

The alternative is storable propellants like the NTO-MMH.

Being out of scope here at this time, these designs have not been explored. Consider that as a future upgrade.

Totaling Up the Mission and Its Launch Requirements

This mission to Mars requires a fleet of 4 vehicles to be

sent from Earth orbit to Mars orbit. One

of these (the manned vehicle) returns to Earth.

The other three are unmanned assets sent ahead earlier by electric

propulsion, for the crew to utilize when

they arrive by conventional rocket propulsion.

The three unmanned vehicles are identical, comprising a dead-head payload and a reusable

solar-electric “tug” that returns to Earth for reuse, after delivery of the dead-head payload into

orbit at Mars.

That dead-head payload payload is the same for each of these

vehicles: an uncrewed but loaded and

fueled reusable Mars landing boat, plus

1/3 of the total Mars lander propellant supply,

plus 1/3 of the crewed vehicle’s Earth return propellant supply. That dead-head payload is 1327.9 metric tons

for each of these 3 vehicles.

Each of these three unmanned vehicles totals some 2413.5

metric tons as assembled in Earth orbit,

that being the dead-head payload plus the fueled SEP “tug”.

The crewed vehicle (the orbit-to-orbit transport) comprises

the crewed and loaded hab section, plus

the loaded Mars arrival propellant tankage,

plus the expendable Earth departure stage that uses cryogenic

propellants. (All the other rocket

propulsion uses the same storable propellants,

and the SEP “tugs” use sublimable iodine to keep the iodine “tank”

weight down.) Ready to depart Earth

orbit, the transport and departure stage

total some 1413.065 metric tons.

The grand total that must be assembled in orbit for the

fleet of 4 ships is some 8653.6 metric tons.

For that, you get 6 landings at

up to 6 different places on Mars, all in

the one manned trip to Mars. That’s

1442.3 tons to support each of the 6 landings,

essentially. These are 2-month

max stays at each landing site. You get all this, plus a “way out” or a self-rescue capability

built into the mission at every step,

plus a fully-healthy crew with radiation shielding and artificial

gravity during the transits, and in low

Mars orbit. That’s a lot of benefit for the cost.

Getting

Landers To Low Earth Orbit

The selected lander design is just about 378 metric

tons, crewed, loaded and fueled. Less crew (and their suits and gear), that’s just about 376.5 metric tons. Just about 294 tons of that lander weight is

propellant. So, a loaded,

crewless, empty-of-propellant lander

is just about 82.5 metric tons. Remove

the supplies, but leave the surface

equipment and rover aboard, and this is

about 77 tons. Completely unladen, the lander is about 75.6 tons.

I looked at SLS (150 metric tons to LEO, guessing $1,000M per launch), Spacex’s “Starship” (100 metric tons to

LEO, guessing $150M per launch), Spacex’s Falcon-Heavy (63 metric tons to LEO

flown expendably, about $85M per

launch), ULA’s Atlas-V (20 metric tons

to LEO at about $85M per launch), and

Spacex’s Falcon-9 (20 metric tons to LEO flown expendably, and $63M per launch).

The loaded unfueled lander mass of 75.6 metric tons is out

of reach of Falcon Heavy, much less

Atlas V or Falcon 9, even if an 8-meter payload

diameter could be flown on any of them. NASA’s

SLS might possibly launch it dry of propellant,

maybe even two of them at once, although

it has yet to fly. That would be 2 or 3

flights of SLS at $2-3B to put 3 landers into orbit, unladen of propellant. It would be 3 flights of “Starship” at $450M

total. The most cost-effective of those

two options is “Starship”. 3

“Starships” deliver 3 landers loaded but unfueled.

At 294 tons of propellant per lander, and 100 tons per “Starship”, some 9 “Starship” tanker flights would be

required to fuel them fully up. At 150

tons per SLS, some 6 SLS flights would

be required to fuel them up fully. At

about 60 tons per flight, some 5 Falcon

Heavy flights could be those tankers per lander, for some 15 Falcon-Heavy flights to fuel the

3 landers up. At 20 tons per

flight, it would require some 45 flights

of Falcon-9 or Atlas-V to fuel the 3 landers in orbit. The most cost-effective way to deliver

these bulk liquid propellant supplies turns out to be 9 “Starship”

flights, with 15 Falcon-Heavy flights a rather

close second. If “Starship”, the transfer crew need not be sent up

separately.

Getting

Earth Return and Lander Propellant Supplies to LEO and Docked

Remember, we must

send to Mars each lander loaded and fueled,

plus 1/3 of its Mars landing propellant supply, plus 1/3 of the transport’s Earth return

propellant supply. These propellant

supplies are pre-loaded tanks. They are

1764.1 tons for the lander operations,

541.3 tons for the transport’s Mars departure, and 455.9 tons for the transport’s Earth arrival. That totals some 2761.3 metric tons of

propellant, which must be in tanks, at about 95% propellant and 5% tank inert.