added 8-16-2025: search code 01062022, search keywords ramjet, aerothermo, airplanes

------

For hypersonic flight vehicles of any kind there are two fundamental problems that require solutions: aeroheating and propulsion. Of these, the aeroheating is the more important! If the design concept does not have a thermal management solution for the extreme aeroheating, then regardless of any propulsion, the design concept has no credibility at all! See References 1 and 2 for more information.

The simplest propulsion solution is rocket. This can take two distinctly-different

forms: (1) a hypersonic glider vehicle

propelled by a large ballistic missile that is staged-off after doing its

job, and (2) a tactical-size hypersonic

missile with its rocket propulsion on-board (which does not preclude

adding a small staged-off booster rocket).

The range and top speed of the big ballistic missile-boosted concept is not

inherently limited, while the tactical-size

vehicle with on-board rocket propulsion is very limited by the weight

and volume constraints pertaining to whatever launches it.

However, if you have

a rocket on board the hypersonic vehicle,

you will have to protect it from the heat that conducts inward

from the hot lateral skins (and the nose tip and any leading edges). Same is true of any payload-related

items. These skin surfaces will have to

operate in the 1000-1500 F (540-820 C) range in order to radiate enough heat

away, to balance the aeroheating input

at stratospheric altitudes, since the

inward conduction simply must be interrupted to protect the rocket (and any

other) internal components.

The maximum recommended service temperature for titanium is

750-800 F (400-430 C). It is very definitely

NOT a high-temperature material, despite

what so many seem to think based on its use in the SR-71. That vehicle was limited to speeds under Mach

3.3, it was definitely NOT hypersonic!

Failing that re-radiation balance, you simply will have to actively-cool

those skins! Why? It is probably very infeasible to dump

such large amounts of inward-conducted heat into the rocket propellant, particularly if it is solid propellant, and for several very compelling reasons. See Figure 1 below.

Hypersonic Airbreathing Propulsion

If one uses airbreathing propulsion to extend the range of a

tactical-size hypersonic vehicle, that

inherently opens multiple further aeroheating problem issues, that are simply not faced by a rocket

vehicle or a glider. You will (at the

very least) have air inlet features and a combustor and nozzle to consider.

The air capture cowl is aeroheated both inside and

outside, but can effectively radiate only

from the outside, and opportunities

for conduction are geometrically absent,

so a higher equilibrium material temperature than a lateral skin is simply

inevitable! Internal inlet ducts obviously

cannot radiate to the environment, and

must not conduct inward, so they will

require active cooling! The combustor

and nozzle will also require active cooling, being either within the airframe unable to

radiate, or else actively aeroheated on

the external surface if exposed. Figure

1 below illustrates these items,

too.

Your choices for airbreathing propulsion are really quite

limited: ramjet, scramjet,

and some sort of combined cycle propulsion (rocket/turbine, ramjet/turbine, or scramjet/turbine). Turbine alone will simply not work at

hypersonic speeds: the fastest operational

gas turbine engine was the short-life design in the Mig-25, at Mach 3.5 maximum in the stratosphere! At Mach 5 in the stratosphere, the captured air temperature exceeds most

turbine inlet temperature limits without burning any fuel at all!

Ramjet

Ramjet works quite well at Mach 3 to 4 in the

stratosphere, and can be readily

designed to survive Mach 5 speeds with the modern technologies. If the vehicle is low drag and

the ramjet engine is ~100% of the vehicle frontal blockage area, Mach 6 is demonstrably attainable, maybe Mach 7.

However, this is possible only

with great difficulty solving the Mach 6-7 aeroheating problems, especially those associated with the inlet

capture, internal inlet duct, and inlet duct-mounted fuel injection

hardware! The only currently-viable

technology solutions for heat protection at conditions like these are one-shot

ablatives. See References 3 and 4

for lots more information about subsonic-combustion ramjet.

Scramjet

Scramjet may well now be almost ready-to-apply

technologically. It has flown

experimentally, but not yet in vehicles

with full aeroheat protections in place. (Update 8-16-2025: there may actually be a couple of scramjet missiles out there, but that technology is still not generally ready for wide application.) These tests were conducted at altitudes so high that the heat transfer

coefficients were reduced by the low air density, reducing the severity of the thermal

management problem for the experimental designs (X-43A and X-51A, plus an earlier Australian test). At such altitudes, airbreather frontal thrust densities are

too low to provide any climb rate, or any acceleration capability in level

flight. These are 100,000 to 130,000

foot (30-40 km).

That high altitude effect has very serious implications for using

airbreathing propulsion for flight-to-orbit,

since the airbreather (any airbreather!) will always have insufficient

thrust to fly, as the air thins

further, just because the ambient

pressure is so low! This is really

why the X-30 project failed! (Rocket

actually has slightly higher thrust at altitude than at sea level, but only if a conventional nozzle is

used; see Reference 5 for why that

last statement is true.)

Combined-Cycle Propulsion Issues

There are two fundamental problems with any (and all) combined-cycle

engine designs that use gas turbine as one component. Problem (1): the inlet diffuser and nozzle geometries required

by the gas turbine are fundamentally incompatible with scramjet (but not

necessarily ramjet), as illustrated in Figure

2 below. Problem (2): there must be zero airflow through the turbine

component, once the max safe speed for

it (only about Mach 3 to 3.5) is surpassed.

The risk is overheating the turbomachinery.

Regarding problem (1),

gas turbines require low subsonic delivery speed at the compressor

face, which means the post-capture

inlet is a divergent diffuser duct that is nearly all-subsonic. Ramjet demands something similar, although not geometrically identical. (See Reference 6 for an explanation of

those differences.) Scramjet demands a

nearly constant-area “isolator duct”, that

is all-supersonic to its outlet! The

very small divergence in that “isolator duct” merely offsets boundary layer

thickening. Variable-inlet-geometry

hardware is well known to be both voluminous and heavy. See again Figure 2.

The turbine outlet speed from a gas turbine is also

generally subsonic. The nozzle must

neck-down to a minimum throat area to reach sonic speed, and may have a very modest supersonic

expansion ratio. Ramjet demands

something very similar, but usually somewhat

larger. Jet fighters use moving “turkey

feathers” that are air-cooled to accomplish the throat and exit area

variations needed. Scramjet cannot

have a neck-down to a min-area throat,

only a supersonic expansion!

And, at high supersonic and hypersonic

speeds, there is simply no such thing

as “cooling air”, which means no

variable geometry nozzle technological solutions exist in anything resembling a

ready-to-apply form! Again, see Figure 2.

Regarding problem (2),

there must be designed-in some way to bypass all (ALL!) the inlet air

around the gas turbine component, directly

to the ramjet or the scramjet component.

Otherwise, the hot high-supersonic

and hypersonic air will simply destroy the turbomachinery, even if it is not turning! This diversion geometry is hard enough to do

subsonically for a ramjet component, and

pretty-much technologically impossible to do supersonically for a

scramjet component, due to the

shock-down risk. And, any such variable geometry inlet hardware is

going to be voluminous and heavy, as

already stated.

Rocket-based combined cycles avoid the

turbomachinery gas temperature problems.

These are essentially variations on the old ejector ramjet, and conceptually could transition to

scramjet, if the ramjet uses a thermal

choke instead of a physical convergence to a minimum throat area. However,

no ramjet vehicle ever flew with a thermal choke, instead always with a physical nozzle! More than half a century ago, tests clearly showed that thermal chokes

resulted in too low a combustor pressure to ever get any effective performance

out of the ramjet.

The true state-of-the-art for these combined cycle

approaches is only concept design with finite-element computer analyses. Not much real testing has been done, and those results were always less than

expected. The design analyses were (and

are) usually made with computational fluid dynamics (CFD), which is still notoriously subject to both

the garbage-in/garbage-out (GIGO) law, and serious problems recognizing

fully-converged numerical solutions.

Here’s the real problem with CFD models: there’s a lot more going on inside any

engine than just compressible fluid flow with this-or-that turbulence model. The physics of combustion are usually

inadequately modeled, and the physics of

flameholding are usually NOT modeled at all,

in most CFD codes. Yet these

effects really dominate the physics in the engine! The “gold standard” is thus still real test

data with real hardware, and there is

actually precious little of that with most of these concepts.

That test data objection applies to both the turbine-based

and the rocket-based combined-cycle concepts.

These are thus nowhere-near ready-to-fly, generally speaking. Which in turn is why you cannot go to a

propulsion company, and just buy one off-the-shelf! These notions get proposed a lot for government

R&D funded efforts, but none have

ever completed any actual development programs.

Effective Propulsion Solutions For Hypersonic Flight

The real solution to these propulsive geometry dilemmas

probably has more to do with “parallel burn” of separate propulsion

devices, than with any sort of

combined-cycle engine approach. Another

name for “parallel burn” is “mixed propulsion”,

which craft such as the Douglas “Skyrocket”, the NF-104,

and the XF-91 had. This took the

form of a rocket engine and a gas turbine engine, on-board separately.

One possible example could be a ramjet vehicle with a built-in

rocket booster, but one able to burn

both engines simultaneously after launch and at very high altitudes, and at landing. As separate propulsion devices, the geometry and performance of each

component can be optimized. Forced to

share otherwise-incompatible geometries,

both components will inherently end up far from optimal.

Hypersonic Airbreathing Propulsion for Orbital Ascent?

The real problem is that thrust of an airbreather (any

airbreather!), and the vehicle lift and drag,

are roughly proportional to ambient

atmospheric pressure, while vehicle

weight is not! At very high

altitudes in the thin air, there is not

enough lift to oppose the normal weight component, and not enough thrust-minus-drag net force

available to overcome the axial weight component, and so thus the vehicle fails to fly

steady-state, much less climb and/or

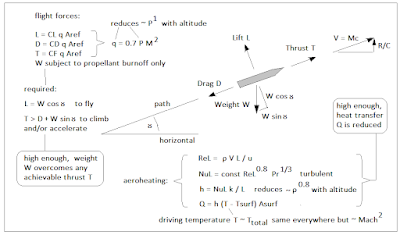

accelerate. This is shown in Figure 3.

This effect is the source of the “service ceiling” for an

aircraft powered by an airbreathing engine (any type of airbreathing

engine!). This is usually specified to

be the altitude at which the rate of climb (R/C) falls under about 200 feet per

minute, which is 3.33 ft/sec vertical

velocity. At Mach 5 (about 5000 ft/sec

velocity), that would be a climbing path

angle near 0.03 degrees. At only 500

ft/sec flight velocity (V), that would

be a climb path angle nearer 0.30 degrees.

Neither is very discernible above horizontal. And THAT is the

point here: effectively that is no rate

of climb capability, no matter how long

you try.

Lower down, where the

air is thicker, these forces become far

more favorable, but the aeroheating and

drag problems to overcome are far worse.

This is because the heat transfer coefficients are roughly proportional

to atmospheric density raised to a fractional power near 0.8, not 1.

That assessment comes from the usual formulation of the Nusselt number

correlations from Reynolds number:

constant x Reynolds number-to-the-0.8 x Prandtl number-to-the-1/3, for turbulent flow. See again Figure 3.

That aeroheating effect and the drag are what drive the need

to be at really high altitudes as the vehicle speed approaches orbital

values. Yet for

thrust-relative-to-weight purposes, the airbreather

needs to be at very much lower altitudes! That fundamental design requirements

incompatibility is quite stark!

You overcome it by using rocket propulsion, not airbreathing propulsion, at those very high altitudes in the really

thin air. Or at least use rocket

propulsion simultaneously with your airbreather. Yes, the

airbreather makes its thrust at high specific impulse, but it just does not make very much thrust

in that thin air! The rocket

does. Which is why one should prefer the

rocket, when leaving the atmosphere!

For a two-stage launch system where the first stage is an

airplane of some kind, there are three

important variables to consider at your intended staging condition. In order of importance, they are (1) highest possible speed, (2) path angle at about 45 (or more) degrees

above horizontal, and (3) highest

possible altitude. Speed has the

greatest beneficial effect, altitude the

least.

Path angle is important so that the second stage may fly a

non-lifting gravity-turn trajectory at minimum drag loss, to orbit.

Pulling up at high speed is a large-radius turn requiring a lot of gees

and incurring a lot of drag-due-to-lift loss due to a very high lift requirement. If your first stage can do its trajectory to

arrive at both high speed and path angle, that minimizes the second stage drag loss and

impulse requirement!

But, at all but the

very lowest altitudes, this will

require rocket propulsion as the entire propulsion system, or at least in combination with the

airbreather in parallel burn. No

airbreather of any kind used alone will be able to do this kind of beneficial

first stage trajectory, precisely

because of the thin-air “service ceiling” effect at higher altitudes.

How Big A Threat Is This New Hypersonic Weapon Stuff, Really?

So, there are very

good reasons why the new “hypersonic weapons” currently being ballyhooed in the

press are just rocket-powered tactical missiles with a peak speed above Mach 5. Otherwise,

they are just hypersonic gliders dispensed from a large ballistic

missile flown on a low, rather

flat, trajectory. The “scramjet missiles” are still

experimental items, not really fieldable

weapons, for a while yet.

The old, retired

AIM-54 “Phoenix” rocket-powered missile had a peak speed of just about Mach 5, way back in the 1970’s. So, what

is so “new” or threatening about reprising that? Nothing!

We have had maneuverable re-entry vehicles as space capsules

since the 1960’s, and as ballistic

missile warheads since the 1980’s. The

space shuttle was another. There is nothing

“new” there!

For the “hypersonic gliders” to be much of a military

threat, the launcher has to fly a much

lower entry trajectory, at a very shallow

angle below horizontal, very unlike

the usual strategic ballistic missile. Otherwise,

there is no time to maneuver the glider before it impacts. That’s just high school physics!

This “new hypersonic glider threat” is really no big

deal, if you know to watch for

those depressed ballistic missile trajectories. And we do.

I just told you, if no one else

did.

References

In addition to the six references cited above, there is a seventh very useful item, for those who wish to research this topic further

and deeper. It is included in the list here

as Reference 7. That one contains

lists of articles sorted by the topic area.

One of those topic areas is “aerodynamics and heat transfer

articles”, where I put the high-speed

aerothermodynamics stuff, among some

other things. The hypersonics-related

stuff is there, right up to entry

heating models. There’s also topic areas

for “ramjet” and “rocket” stuff, and

much more. All of these are articles that

I wrote and published on this “exrocketman” site over the last several years.

To find any such article quickly, use the navigation tool on the left side of

the page. You will need the posting date

and the title (jot them down). Click on

the year, then month, then the title (if need be).

You can click on any figure in an article to see

enlargements of all of the figures in the article. There is an X-out option at top right of that

page, which takes you right back to the

article itself. Update 8-16-2025: search codes added to the reference list, and to the references themselves.

#1. 2 January 2020, “High Speed Aerodynamics and Heat Transfer” (physics and calculation models) search code 01012020

#2. 12 June 2017, “Shock Impingement Heating Is Very Dangerous”

(physics with X-15 as an example) search code 12062017

#3. 10 December 2016, “Primer on Ramjets” (basic concepts and

fundamentals) search code 10122016

#4. 21 December 2012, “Ramjet Cycle Analyses” (how these things are best calculated) search code 21122012

#5. 12 November 2018, “How Propulsion Nozzles Work” (covers

conventional and free-expansion) search code 12112018

#6. 9 November 2020, “Fundamentals of Inlets” (same components

used quite differently for ramjets and gas turbines) search code 09112020

#7. 21 October 2021,

“Lists of Some Articles By Topic Area” (dates and titles arranged by

topic) search code 21102021

Figure 1 – Heat Transfer Issues With Hypersonic Flight

Figure 2 – Geometric Incompatibilities Among Airbreathing Concepts For Hypersonic Flight

Figure 3 – Thin-Air Effects On Thrust, Lift, Drag, and Aeroheating at High Altitudes

Addendum 6-11-22:

Here is a plot about the flight test space covered by the X-15 program, relative to the aerodynamic ascent path to low Earth orbit. The lower altitudes correspond to higher speeds reached by the X-15. The higher altitudes correspond to lower speeds achieved.

The X-15A-2 variant was able to reach 4520 mph (Mach 6.7) at 19.3 miles altitude, still near the left end of that ascent corridor. It was carrying a scramjet test article on its ventral fin stub during this flight. The shock wave off the scramjet inlet compression spike nearly cut the tail off the bird from shock impingement heating effects.

Now bear in mind that shock impingement effects multiply (considerably) the heating rates, but not the plasma temperatures themselves. All that means is that the structures affected are going to soak out very quickly, to very near the plasma driving temperature, pretty much regardless of what the designer might have done in the way of cooling provisions.

At the X-15A-2 peak speed conditions, that plasma sheath temperature was some 3070-3080 F, far beyond the capability of even the Inconel-X skin material. The white ceramic coating applied to this particular variant would have been able to do very little about this fast soak-out effect at the shockwave impingement locations. So, it is not surprising at all (in retrospect) that the craft suffered so much damage.

Update 6-12-22:

A lot of folks are using the word “hypersonic” very

loosely. Too loosely. I have even seen the SR-71 termed

“hypersonic”, when it most definitely

was not, at a max allowable cruise speed

of Mach 3.2 at some 85,000 feet. Pilots

would pull up and reduce throttle to slow down quickly, if it ever reached Mach 3.3, to avoid engine and airframe damage. I have talked to a couple of them, and that is what they told me.

There is a formal definition: “hypersonic” is that speed at which the shape

of the shock wave system about the vehicle no longer changes its shape appreciably

as flight speed increases further. The

speed at which that happens depends upon the shape of the vehicle.

For “pointy” shapes likes missiles and aircraft, it is just about Mach 5, or a velocity that is 5 times the speed of

sound. For really blunt shapes like

space capsules traveling heat shield forward,

it is just about Mach 3. Those

two values are the rules of thumb for “hypersonic”, for those two classes of shape.

Here is a further update to the figure showing the ascent

corridor and the X-15 data. I have added

a typical vertical-launch trajectory,

and some effective temperatures in the plasma sheath about any

vehicle. I also show how precipitously

the heat transfer coefficient drops as altitude extremizes. That is why the peak heating rate point is

somewhere in the middle of the ascent corridor,

not its high-speed end.