Update 7-5-2025: added search code 11032024. The most telling trends are plotted in Figure 25.

--------

Update 6-8-2025: this article is the continuation of a study originally posted 3 March 2024, titled "Launch to Low Earth Orbit: 1 or 2 Stages?". That study produced some broad recommendations, this one produces actual trends of payload fraction and launch weight vs propellant combination, for the all-expendable TSTO and SSTO scenarios.

----------

Because of repeated questions from knowledgeable readers, I took a more refined look at the scenario of chemical launch to eastward LEO at low inclination, using either an expendable two-stage to orbit design (TSTO), or an expendable single-stage-to-orbit design (SSTO). For this more refined look, I added delta-vee (dV) budgets for rendezvous and deorbit, I looked at a more representative orbital speed requirement, and I let the second stage of a TSTO shoulder a minority of the gravity loss (the split being arbitrary). The first stage shoulders all the drag loss. The SSTO shoulders all of both losses. See Figure 1.

Figure 1 – Revised dV Requirements That Are More Realistic

The 75-25 split on shouldering gravity losses is

arbitrary, but “in the ballpark”. I still picked 5% each for gravity and drag

losses, the basis being the kinetic

energy-equivalent surface circular orbit speed.

5% gravity loss would go with good kinematics off the launch pad, meaning 0.5 gee above gravity or better, or a thrust/weight of 1.5 or better at

launch. 5% drag loss would go with a

clean, slender shape, really meaning a length/diameter ratio of 6

or larger, with no steps in

diameter.

TSTO

Design Considerations

For the TSTO, what I

presumed was LOX-RP1 propulsion in the first stage, “compromise”-sized to improve the

ascent-averaged specific impulse (Isp),

such that the engine is just barely unseparated firing at sea

level, at 85% of max chamber pressure

Pc. I presumed LOX-LH2 propulsion in

the second stage, sized at an expansion

area ratio (A/A*) = 100, to limit engine

length.

Both the first and second stage engine technologies were

presumed to be modest technologies that do not push the state of the art (SOTA)

very hard, something that lowers

development costs that must be amortized over the launches to be made. Accordingly,

I presumed only a max Pc = 2500 psia,

and that whatever cycle it is has,

has a dumped bleed fraction of 2%.

The pressure turndown ratio (P-TDR) for throttling is only 2.5. The usual curved bell of 18-and-8-degree

profile is presumed, along with a throat

area discharge coefficient CD = 0.995.

Rather modest stage structural design technologies were also

presumed, such that both loaded-stage

inerts were 5% of stage ignition mass,

again to reduce development costs that must be amortized over the

launches to be made. 4% has been

demonstrated, but requires custom

alloys, even for expendables. The definitions are such that payload

fraction plus inert fraction plus propellant fraction sum to 1. The first stage payload is the fully-loaded

second stage, and the second stage

payload is a fixed 100 metric ton mass riding out in the open, atop the second stage.

All propulsion was initially sized for a thrust requirement

of 500,000 lb (226.76 metric tons-force,

2223.7 KN). For any ascent

engine, this was imposed at sea

level. For the TSTO second stage, this was imposed in vacuum. Performance was computed vs altitude, and those values averaged over the list of

altitudes in the altitude table.

That is not exactly correct for an “ascent-averaged

Isp”, because the vehicle does not spend

equal time at all these altitudes, but

it is well within the “ballpark”. I

compensated for any error by presuming an Isp about 2-5 s below what the sizing

calculation said. Dimensions and flow

rates depend upon sized thrust. Flow

rates and cross sectional areas scale in proportion to thrust, while linear dimensions scale in proportion

to the square root of thrust. Isp does

not scale.

The TSTO first stage sea level engine sizing to 500,000 lb

thrust is shown in Figure 2. The TSTO

second stage vacuum engine sizing to 500,000 lb thrust is shown in Figure

3.

Figure 2 – As-Sized TSTO First-Stage Engine Data, Un-Rescaled

Figure 3 – As-Sized TSTO Second-Stage Engine Data, Un-Rescaled

SSTO

Design Considerations

For the SSTO, I

looked at both LOX-LCH4 propulsion and LOX-LH2 propulsion. Such engines were “compromise”-sized for

better ascent-averaged Isp, just like

the first stage engines in the TSTO design. However,

the technology baseline presumed, pushes the SOTA very hard indeed: these designs presume a max Pc = 4000

psia, a cycle such that the dumped bleed

fraction BF = 0, and a more challenging

P-TDR = 3. (They would compare to the

SpaceX Raptor designs.)

I kept the same rather modest stage structural design

technology, with a stage inert fraction

of 5%. In this case, there is only one stage, and its 100 metric ton payload rides out in

the open, atop the stage, exactly the same as was presumed for the

TSTO.

The hydrogen-fueled version looked good enough to check the

effects of just modest-technology. That

would use the LOX-LH2 propellant ballistic models, but employ the same reduced Pc and

non-zero-BF that was used for the TSTO engine designs. The methane-fueled version had a low-enough

payload fraction to warrant skipping this look.

Figure 4 shows the un-rescaled methane engine results

for the edge-of-the-SOTA. Figure 5 shows

the un-rescaled hydrogen engine results for the edge-of-the-SOTA. Figure 6 shows an un-rescaled hydrogen

design of the same modest-technology parameters as were used in the TSTO

design.

Figure 4 – As-Sized SSTO Methane Engine, Edge-of-the-SOTA, Un-Rescaled

Figure 5 – As-Sized Hydrogen Engine, Edge-of-the-SOTA, Un-Rescaled

Figure 6 – As-Sized Hydrogen Engine, modest SOTA,

Un-Rescaled

Doing

More Detail

In my previous posting on this topic, “Launch to Low Earth Orbit: 1 Or 2 Stages?”, posted 3 March 2024, all I did was convert dV’s to mass ratios

MR, turn that into a list of mass

fractions, and then size a weight

statement from a fixed payload mass. I

used the stage ignition masses to size total thrust requirements. And that was it.

I have since added to the simple spreadsheets I used for

that analysis. If you look at the stage

overall thrust requirements and masses to be accelerated, you can choose a number of engines

appropriate for that stage, and thus

from that overall thrust requirement,

determine what those individual engine thrust ratings must be.

I created a little thrust-resize spreadsheet, which takes the as-sized engine data, and rescales them to the necessary thrust

rating. Areas and flow rates scale as

proportional to thrust, while dimensions

scale as proportional to the square root of thrust. What is important is the estimated overall dimensions

of an individual engine. Part of Figure

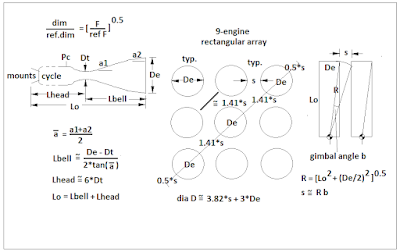

7 illustrates how these engine dimensions are scaled and created from the

estimated engine sizing data.

For only a 9-engine cluster,

I worked out how to use the engine dimensions and an assumed max gimbal

angle to estimate a clearance spacing between engine bells so that gimballing

one will avoid impacting an adjacent bell.

Adding this up along a diagonal of the 9-engine cluster provides an

estimate of the min stage diameter, as

is also shown in Figure 7. I used

15 degrees for the max gimbal angle, an

arbitrary choice.

Figure 7 – How Engine Dimensions Determine Stage Diameter

Once you have a min stage diameter estimate, you can begin to approximate the lengths of

the tanks, engine bays, and interstages. Those lead to a vehicle length/diameter ratio

estimate, from which to judge whether

the “slender” assumption justifying lower drag loss was justified. This is based on the same diameter for the

whole vehicle, to also qualify as

“clean”, for justifying the lower drag

loss assumption.

You can use an estimate of the engine’s operating r-ratio to

split total propellant mass into oxidizer and fuel masses, in each stage. You can use the standard specific gravity

values for those propellant materials to turn those oxidizer and fuel masses

into volumes (specific gravity is numerically equal to density in metric tons

per cubic meter). Dividing volume by

base area gets you a length of the tank that is an underestimate, since there are curved pressure dome

heads. Compensate by assuming an inter-tank

length of about a diameter.

First stage (or single stage) estimated engine length is the

length of the first stage engine bay (if there is one), but is part of the overall first stage length

regardless. If there is a second

stage, there is some sort of interstage

between it and the first stage, whose

length is the estimated overall length of a second stage engine. The length of the payload is arbitrarily

assumed to be 2 diameters.

The resulting augmented spreadsheet image for the TSTO

design is shown in Figure 8. The

leftmost block is the original mass and thrust sizing calculations. The rest is what I added to determine engine

counts and thrusts, and to use the

re-scaled engine dimensions to do the volumes and lengths. Images of the rescaled kerosene and hydrogen

engine spreadsheets were not included,

but are reflected in the dimensional data input at top right.

Figure 8 – Spreadsheet Image For TSTO Detail Sizing

A somewhat similar-looking spreadsheet was used for the SSTO

designs, starting with the LOX-LCH4

design looked at initially in the earlier posting. That produces the detail sizing spreadsheet

image of Figure 9, and the

associated engine re-scale spreadsheet image of Figure 10.

Figure 9 – Spreadsheet Image For SSTO Detail Sizing, Methane,

Edge-of-SOTA

Figure 10 – Spreadsheet Image For SSTO Engine Re-Scale, Methane,

Edge-of-SOTA

The reader should be aware of one disconnect here: I picked 15 engines, not 9!

The stage diameter estimate is wrong:

it is too small! That lowers the

vehicle L/D ratio even further, from the

too-low value already obtained. For this

design, the drag dV loss to cover should

have been more than the 5% used in the velocity requirements analysis shown in Figure

1 above.

So as it turns out,

the recommendation in the earlier posting to use the LOX-LCH4 propellant

combination for the SSTO design has been shown to be wrong! This also shows up in the 2.1% payload

fraction and the enormous 4850 metric ton ignition mass, given in Figure 9 above.

Accordingly, I did

another edge-of-SOTA design for the SSTO,

this time using LOX-LH2 propulsion.

The image of the detail sizing spreadsheet is given in Figure 11. The engine dimension re-scaling is shown in Figure

12. This one actually uses 9

engines, so the diameter is

“right”, and so is the L/D.

Figure 11 -- Spreadsheet Image For SSTO Detail Sizing, Hydrogen,

Edge-of-SOTA

Figure 12 -- Spreadsheet Image For SSTO Engine

Re-Scale, Hydrogen, Edge-of-SOTA

Comparing the payload fractions and ignition masses between Figures

8 and 11, 7.5% and 1401 tons TSTO vs

7.5% and 1325 tons SSTO, we see pretty

much equivalent performance between the TSTO using LOX-RP1 and LOX-LH2 both at

modest engine SOTA, and the SSTO using

all-LOX-LH2, but at the edge of the

engine SOTA. Clearly the higher average

ascent Isp of the hydrogen vs the methane made a huge difference for the

SSTO, more than I initially expected

to see!

That brings up determining the effects of pushing the engine

SOTA so hard with the SSTO engines. To

determine that, I used the modest SOTA

hydrogen ascent engine data of Figure 6 above, to create yet another SSTO design

sizing, by these same methods. The detail sizing spreadsheet image is given

in Figure 13, with the engine

re-scale data in Figure 14.

Figure 13 -- Spreadsheet Image For SSTO Detail Sizing, Hydrogen,

Modest SOTA

Figure 14 -- Spreadsheet Image For SSTO Engine

Re-Scale, Hydrogen, Modest SOTA

This one is not that much reduced in payload capability

(6.7% vs 7.5% for the Edge-of-SOTA SSTO and the TSTO). It increased its launch mass a little, being 1487 metric tons, vs 1325 for the edge-of-SOTA SSTO and 1401

for the TSTO. Yet they are all 3 in the

same basic class of vehicle sizes. I did

select 9 engines, so the diameter is

valid, and the L/D is “good”. There is no reason the more modest

hydrogen engine technology might not serve,

and serve well.

Results

and Conclusions

Sketched images for the TSTO with

modest-technology kerosene and hydrogen propulsion, the SSTO with SOTA methane propulsion, the SSTO with SOTA hydrogen propulsion, and the SSTO with modest-technology hydrogen

propulsion, are given in Figures 15

through 18 below, respectively.

As the table above indicates, it is ascent-averaged Isp that is the

critical factor here with the SSTO.

The big gulf between the methane and hydrogen/SOTA ascent-averaged Isp’s

corresponds to the big gulf between the payload fractions and the ignition masses. The small gap between the hydrogen/modest and

hydrogen/SOTA Isp’s corresponds to the small gap between payload fractions and

ignition masses.

Changing the propellant combination had a huge effect on

ascent-averaged Isp and the resulting sized designs. Changing how hard the hydrogen engine

technology pushes the SOTA did not have a large effect, only a smaller one. The sized design reflects exactly that. See also Figure 19 below.

Before I ran this more detailed design study, I thought that pushing the SOTA vs a modest

technology would have more of an effect than it actually did. Now we see:

the propellant combination has the far stronger effect. Go ahead and use the more modest engine

technology. That will not stop you from

doing rather well as an SSTO, as long as

you use LOX-LH2.

The hydrogen upper stage TSTO with modest engine technology

is only a little better in terms of payload fraction than the hydrogen SSTO

with modest engine technology. But, it does offer an easier path to partial

reusability, by substituting a larger

lower stage with the ability to fly back and land. That is something to consider.

The “compromise” expansion sizing approach for ascent

engines is very important, as that is

how one achieves ascent-averaged Isp values higher than an ordinary sea level

design.

That sort of “ascent-averaged Isp is dominant” outcome for

the SSTO makes me wonder if we could do better than a kerosene first stage for

the TSTO. While beyond scope here, I will look at that in a future update or

posting. The candidates are methane and

hydrogen, of course. These will be restricted to “modest engine

technology”. The same methods will be

used, as were used here.

I do expect that one or both will significantly exceed what

we can do with a modest-technology hydrogen SSTO. The problem will be the same volume issues

that afflicted the SOTA-technology methane SSTO. But we will not know, until we try.

Figure 15 – Image of Detailed Results for TSTO, Modest Kerosene and Hydrogen

Figure 16 – Image of Detailed Results for SSTO, SOTA Methane

Figure 17 – Image of Detailed Results for SSTO, SOTA Hydrogen

Figure 18 – Image of Detailed Results for SSTO, Modest Hydrogen

Figure 19 – Plots Showing Relative Effect of Engine

Technology Level and Propellant Combination

-----

Update 3-12-2024:

I carried out the plan outlined at the end of the article

above, to investigate two

higher-performing propellants in the TSTO.

That required sizing a LOX-LCH4 engine of modest technology to be an

ascent engine in the first stage. I

already had a LOX-LH2 ascent engine sized,

of modest technology,

investigated for the SSTO. These

were both resized to fit a 9 engine cluster of the necessary thrust, just as in the studies done in the article

above, with the updated vehicle sizing.

For these changes to the TSTO, I did not change its second stage at

all. It was, and still is,

powered by two small LOX-LH2 engines of modest technology, sized as vacuum engines with A/A* = 100, just as before. The resized modest-technology methane ascent

engine is illustrated in Figure 20 below. The sized TSTO vehicle with that set of modest

technology methane engines in its first stage is depicted in Figures 21 and

22 below. The sized TSTO vehicle with a set of modest technology hydrogen

engines in its first stage is depicted in Figures 23 and 24 below.

I did not see much difference between the kerosene and

methane first stage TSTO vehicles in terms of payload fraction, but the ignition weight did reduce somewhat, going to methane. A part of this is the reduced thrust

requirement reducing engine lengths, in

a vehicle whose length and diameter are primarily sensitive to engine

dimensions and number. With a hydrogen

first stage, the payload fraction

increased noticeably, and the launch

weight decreased significantly further.

I had not reduced the ascent-average Isp of the modest

technology hydrogen ascent engines by 2-5 s when I did the hydrogen TSTO in the

article above, inputting 447 s to the

vehicle sizing. Here, I did,

inputting 445 s Isp to the vehicle sizing. I ignored this small difference

making the comparison plots of trends with the two vehicles, which is Figure 25 below. The main takeaway is the lower slopes of the

trends with the TSTO, compared to the

steep slopes of the trends for the SSTO.

There is a good, simple reason for that: the TSTO second stage is vacuum hydrogen-powered, and shoulders the majority of the dV requirement imposed on the vehicle. That makes the first stage mass ratios rather small in comparison, where the added benefit of higher first-stage Isp is “diluted” by the constant-second stage effects. In contrast, the SSTO has to get all the dV requirement out of its single stage. The benefits of the higher Isp are entirely undiluted by anything, hence the effects are large, and the trend slopes are steep.

Figure 20 – Sized Methane Ascent Engine of Modest Technology

Figure 21 – Vehicle Sizing Data for Modest-Technology

Methane Engines in the First Stage

Figure 22 – Vehicle Sketch for Modest-Technology Methane

Engines in the First Stage

Figure 23 – Vehicle Sizing Data for Modest-Technology

Hydrogen Engines in the First Stage

Figure 24 – Vehicle Sketch for Modest-Technology Hydrogen

Engines in the First Stage

Figure 25 – Comparison Plots of Trends, With All Vehicles

Conclusions

The results here are for all-expendable vehicle

sizings. The conclusions apply to the

same, with exceptions for re-usability as

stated in notes 7 and 8.

#1. If you design a TSTO expendable “from scratch” for

delivering large payloads to LEO, always

use a LOX-LH2 engine designed for vacuum operation to power the second

stage.

#2. If you design a TSTO expendable “from scratch” for

delivering large payloads to LEO, it

does not matter very much which of the 3 propellant combinations you use for

powering the first stage. The trends

favor LOX-LH2, but these trends are weak

(low slope). LOX-RP1 and LOX-CH4 also

serve well.

#3. Whether you design “from scratch” a TSTO expendable or

an SSTO expendable for delivering large payloads to LEO, use “ascent engines” with their expansion ratio

designed as an ascent compromise: just

barely unseparated, at around 85% max Pc,

at sea level. Engines designed in this way will have a

higher ascent-averaged Isp than traditional sea level engine designs, which are generally perfectly expanded to sea

level pressure at max Pc. And the actual

flight configurations are testable at

sea level in the open-air nozzle mode,

which helps to greatly lower development costs that must be

amortized, and to greatly lower

development risks.

#4. If you design “from scratch” an SSTO expendable for

delivering large payloads to LEO, go for

the LOX-LH2 propulsion. Because of the

steep trends, these designs are critically-sensitive

to ascent-averaged Isp above all other considerations. Only LOX-LH2 provides high enough Isp.

#5. Neither type of vehicle is extremely-sensitive to how

hard the engine technology pushes the SOTA,

because the Isp difference is not all that large between high-SOTA and

rather modest technology, something true

for all 3 propellant combinations. With

the more modest technology, development

risks and efforts are lower, leading to

lower development costs to be amortized.

#6. I did not evaluate the impact of stage structural

design technology! I got good results

from the best of the designs at a rather modest stage inert mass fraction

assumption: 5% inert in every loaded

stage. 4% has been demonstrated, but I deliberately chose not to push those

limits! The less demanding structural

design lowers development effort levels and development risks, thus lowering the development costs to be

amortized.

#7. The TSTO offers a fairly easy path to partial

re-usability, by enlarging the first

stage design to enable its flyback,

entry, and recovery. This is primarily enabled by the relatively-low

(only supersonic) speeds at entry, in

turn imposed by the relatively low staging speed, which also lowers the burn-back dV

requirement.

#8. The SSTO does not offer an easy path to

re-usability, because the entry speeds

are orbital-class hypersonic, and the

stage simply does not have the inert fraction to permit the design changes to

make it into a survivable entry vehicle at all,

much less to land. The “proof” is

in the negative: if this were not true

as stated, it would have already been

done, routinely, along with first stage recoveries.

Final

remarks

Do not take these “designs” as ready-to-build! While the engine ballistics and performance

estimates are rather good, the weight

statements are less so, and the

dimensional estimates are only “ballpark”.

It is the trends that should be used to support real design

candidate screening and selections. Some

of that screening I have done for you,

in this article.

To address questions from knowledgeable readers, I made the dV requirements more

representative of vehicles that can get to orbit and rendezvous with a

destination, plus a deorbit capability

for proper disposal. But, there are a lot of things that I did not

address.

I did not address propellant ullage / engine relight

issues, and I did not address the

unrecoverable propellant fractions that are inherent with any type of tank

design. Further, I did not address the actual end dome

shapes or designs of the liquid propellant tanks, or the possibility of a common dome

design, which can be done with some

propellant combinations, but by no means

all of them.

These are not only “from scratch” vehicle ballpark design

sizings, they are also “from scratch”

paper engine design sizings, a

start-point only for a real engine design and development effort. I made absolutely no attempt in this

work, to use any pre-existing engine

designs of any kind at all!

My work here can be re-scaled to other delivered payload

masses (the 100 metric tons that I used here was an arbitrary number), so that the trends I uncovered can help guide

real concept selection and real design efforts for other-size projects done by

others. If a pre-existing engine of the

right propellant combination fits your design project, so much the better! Any development costs you can avoid are one

less thing to amortize over the life of the product.