Bounding Analysis for

Lunar Lander Designs

GWJ 3-18-17 completed 3-18-17

The scenario here is a lander delivered “neat” to lunar

orbit as an unmanned item. A crew will

arrive separately to rendezvous with it in lunar orbit. The plane of that orbit is presumed to be

very close to the ecliptic. Orbital

direction is retrograde, in accordance

with the figure-eight patched-conic trajectory used during Apollo. The delta-vee to land one-way is 1.68

km/s. For design purposes, a few percent higher is used to provide a

little margin: 1.75 km/s.

The lander is delivered “neat” to lunar orbit, meaning the rocket that takes it to the moon

must do the “burn” to put it into lunar orbit.

The total rocket design delta-vee from the surface of the Earth to do

that is at most 12.4 km/s, when the

first 8 km/s to Earth orbit is factored for drag and gravity losses by

1.05. This is very close to the surface

launch for a more-or-less worst-case slow trajectory to Mars, which is about 12.1 km/s, factored the same way. That way, the tonnage sendable onto a Mars transfer

trajectory is almost the same as what can be delivered into lunar orbit, for our purposes here.

Descent Design

Requirements

Spacex lists on its website that its Falcon-Heavy can send

13.6 metric tons to Mars, flown

fully-expendably, for about $90 M launch

price. This heavy-lift booster hasn’t

yet flown, but it should fly this year

(2017). Reducing that payload slightly

for the slightly-higher delta-vee to lunar orbit, call that a max payload to lunar orbit of an

even 13 metric tons.

For the descent stage,

ready to fire in lunar orbit, we

are looking at an ignition mass of 13,000 kg maximum, and a required design delta-vee of 1.75

km/s. Propellants should be

storable, since days to weeks, even months,

in space (or on the moon) are contemplated. With nozzles designed for vacuum, and assuming NTO-MMH propellants, a delivered Isp = 335 sec is quite realistic. Engine thrust/weight ratio of 100

Newtons-of-thrust per Newton of engine Earth weight seems feasible.

Thrust to ignition Earth weight ratio should

just barely exceed lunar gravity’s pull,

so that plenty of thrust margin is available at burnout weight: 0.2 seems “reasonable”. We’d like the vehicle acceleration at burnout

to be less than 1 gee, preferably under

0.5 gee, to keep the ride from being too

rough, and to limit throttleability

requirements to feasible values.

The propellant tanks will need a sun-reflective surface and

some insulation, plus electric in-tank

heaters, on a single-hull tank. That means the descent stage propellant

tankage will not be quite as lightweight as that of an expendable booster. Just considering the tankage alone, a 95-5 split of propellant to tank masses

seems reasonable to assume (Wp/Wt = 95/5 = 19).

The rest of the stage structure must bear the thrusted

flight maneuvering loads carrying as large a payload as possible, plus incorporate a set of broad-span landing

legs, and some means of unloading large

items (ramps, crane, etc.).

An inert structural fraction for the stage near 15% should cover all of

this. That fraction does not include

tank inerts or engine hardware. Those

get figured separately, and then added

to determine an overall stage inert mass fraction.

The objective here is to determine max payload mass within

that ignition mass limitation. That

payload can be either (1) cargo delivered one-way, or (2) an ascent vehicle carrying minimum

crew and cargo weight. They mass the

same, though.

Sizing a “Clean-Sheet”

Bound on the Descent Stage

Exhaust velocity is rather accurately estimated as Vex, km/s

= 9.8067*(Isp, sec)/1000. That and the

design delta-vee value combine to determine stage mass ratio MR =

exp(dV/Vex). The required propellant

fraction (of ignition mass) is Wp/Wig = 1 – 1/MR. The corresponding fraction for tankage inerts

is Wt/Wig = (Wp/Wig)/(Wp/Wt). The

corresponding engine inert fraction of ignition mass is We/Wig = (T/Wig)/(T/We). The rest of the stage structural and

equipment inerts is represented by the 15% figure. These total together for the overall stage

inert fraction.

Payload fraction of ignition mass is just 1 minus the

propellant fraction and minus the sum total inert fraction. Once you specify an absolute payload

mass, that determines ignition

mass, from which all the component

masses are determined by their fractions.

That finalizes the weight statement.

For this bounding exercise based on Falcon-Heavy delivery, those results are in Figure 1.

Figure 1 – Limits for Descent Stage, One-Way,

Falcon-Heavy Delivery to Lunar Orbit

Payload is 5.372 metric tons. This could be all cargo, or it could represent a crewed ascent

stage. If cargo, that’s $90M/5.372 metric tons = $16.8M per

metric ton delivered to the surface of the moon. Actually,

you design to a slightly-smaller payload mass, because of all the uncertainties. There is always the unexpected outcome, when sizing vehicles like this “from

scratch”. The weight margins don’t have

to be all that large, because I already

put that into the design delta-vee figures.

Ascent Design

Requirements

The same propellant and tankage choices are presumed. The same engine T/We is assumed. A slightly-higher T/Wig = 0.3 is assumed, to accelerate “smartly upward” against lunar

gravity. Stage inert fractions can be lower

since no unload equipment or landing legs are needed. However,

these inerts are likely higher than a typical booster rocket (5%) because

of the protective cabin surrounding the crew,

the docking hatch, and the instruments

and controls they must use. I simply assumed

10%.

This ascent stage must ascend to lunar orbit (requiring 1.68

km/s), and also maneuver to rendezvous

with the crew return craft left in lunar orbit.

It therefore needs more design delta-vee than the descent stage. Call it 2.0 km/s, for a kitty of 0.3 km/s to cover maneuvering

and the unexpected.

Its maximum ignition mass cannot exceed the descent stage

payload capability of 5372 kg. Prudence

dictates very slightly less. Call it

5360 kg for design-bounding purposes.

Sizing a Clean-Sheet

Ascent Design to Fit the Descent Stage

Figure 2 – Limits for Ascent Stage, One-Way,

To Fit Descent Stage That Falcon-Heavy Can Deliver

For the sake of argument,

use 80 kg per person body weight,

and 120 kg for a surface EVA-capable pressure suit. That’s 200 kg per person. Set food,

water, and breathing oxygen

supplies to 100 kg to cover an unexpectedly-long rendezvous interval of several

days. That’s 300 kg allotted per

person. There’s “room” for 7 such masses

in the payload.

If this were 6 crew,

there’s room for around 300 kg of samples or return cargo. If the crew is 5, there’s room for about 600 kg of samples or

return cargo, and so forth. But the point is, there’s room for a much larger crew than

Apollo had. That’s partly the difference

in technologically-achievable storable propellant performance, and in structural technologies, since the 1960’s. The rest is landing without unknown obstacles

in your path, which is what happened on

Apollo 11, nearly depleting its

propellant.

How This Can Be Used

The one-way cargo-only variant can be used at $90M a shot to

deliver 5.36 metric tons of cargo to the moon ($16.8 M/delivered metric ton). Several could be sent to the same site. Some of these could be the modules from which

some sort of surface habitat could be assembled. The rest could be the supplies, equipment,

and surface rover vehicles needed to operate that base.

The manned lander conforms to the same 5.36 metric ton

weight limit. If crew were 3, then 1200 kg of surface supplies could go

down with them. If crew were 2, then 1500 kg of cargo could ride down. Reducing the ascent load just increases the

rendezvous maneuver capability upon returning to lunar orbit, a very beneficial safety factor.

Say, we sent 9 of

these to the moon: 6 cargo-only landers

and 3 landers with manned ascent stages,

each with a crew of 2 and 1500 kg of cargo on board. That gives us three ascent vehicles on the

lunar surface ready to use, when the

entire crew really only needs one to return.

Added safety, that is.

That’s a total of 32.16 tons delivered with the cargo

landers, and 4.5 more tons sent down

with the manned landers, for a total crew

of 6. Assume simply for the sake of

argument that the surface habitat requires 20 tons. We need to reserve 0.6 tons of supplies for

the crew to ascend. Assume two rovers, each 1 ton.

Assume one electric backhoe-like device, at 2 tons.

36.66 tons total delivered cargo, less 20 ton habitat, 4 tons for vehicles, and 0.6 tons for ascent supplies, leaves 12.06 tons allocatable for surface stay

supplies and other equipment items. At a

nominally-assumed 10 kg life support per person per day for 3 months, then about half that 12 tons is something

other than life support supplies. Also nominally, 3 months of life support supplies for a crew

of 6 is pretty close to a lander’s deliverable payload at 5400 kg. I tried to overestimate this requirement.

Looks to me like there is very good potential for

establishing a fairly substantial lunar experiment station, temporarily occupied for a considerable time

(at least 3 months). This requires 9

Falcon-Heavy fully-expendable launches for the landers, plus one more to send the crew in a crew

Dragon (with its trunk modified to carry propellant, something not addressed here), for $900 M in launch costs. If launch costs were 20% of the program that

develops these vehicles and the surface equipment, total program cost to put a small base

temporarily on the moon would be in the ballpark of $4.5 B.

Launching another cargo lander every 3 months or thereabouts

brings the supplies to keep that base permanently occupied at crew size 6. Maybe switch out crews yearly, by adding a crewed Dragon to lunar orbit

along with a fresh manned lander to take them down to the surface. That’s a total of 6 Falcon-Heavy launches per

year to maintain a continuous presence at the base. That’s $540M per year to maintain the base

after it is built, plus the costs of keeping

the necessary vehicles and equipment in production. Development is complete, so call launch costs ~50% of continuing

program costs.

About $4.5 B to establish a 3-month-capable, 6-man base on the moon, and about $1B/year to keep it continuously

manned and operating is just not very expensive as space ventures go! This analysis is based on the use of a

commercial heavy lift rocket that is far less expensive to use than NASA’s

SLS, and which will also be far more

available for routine use multiple times per year, than NASA’s SLS ever can.

Blue Origin is also planning to get into this kind of lunar

capability with its New Glenn rocket.

Between them and Spacex, putting

a base on the moon looks to be quite feasible and quite affordable. This could provide the bootstrap start needed

to begin doing something useful, or for

profit, on the moon.

Final Remarks

This kind of experiment station allows evaluation of

low-gravity effects upon health versus the zero-gravity effects that we are

familiar with in Earth orbit. It allows

a place to experiment with increasingly-capable recycling life support

systems. It allows a place to experiment

with meteoroid and radiation protection by regolith cover. It allows a place to experiment with ways and

means to overcome contamination and wear issues with very-fine-but-sharp-edged

dust particles. All these are needed to

visit Mars or the asteroids, and are

available on the moon “close by” in case of trouble.

The same base allows experimentation with ways and means to

dig and drill deep in a harsh environment.

It allows experimentation with the recovery of mineral resources. It allows experimentation with how to

establish roads under such conditions,

so that future long-distance surface transport becomes feasible. These things are needed for establishing

useful and prosperous industrial applications on the moon and Mars, and to some extent the asteroids.

This is the kind of thing we should have attempted to close-out

Apollo, had a useful lunar presence been

the goal, instead of

“flags-and-footprints”. It is still a

good rationale for returning and doing something very much like what I

described here, as a first step.

Addendum: Crew Dragon Modified to Leave Lunar Orbit

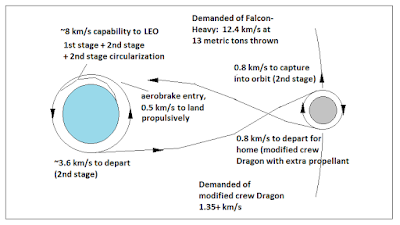

The “design” trajectory to reach lunar orbit is pretty much

the same as was used for Apollo decades ago. A direct launch from Canaveral into low Earth

orbit more or less eastward at low inclination (the part requiring factoring

ideal delta-vee for gravity and drag losses),

followed by a burn to escape onto the lunar transfer trajectory, and a final upper-stage burn to place the

payload into a retrograde orbit about the moon.

The worst-case total rocket design delta-vee for this is just about 12.4

km/s (factored), and worst-case 0.8 km/s

to leave lunar orbit onto a trajectory home.

See Figure 3.

Figure 3 – Design Trajectory and Delta-Vee Requirements

Design Requirements

for Modified Crew Dragon

Total delta-vee capability 1.35 km/s min, 1.40 preferred. Maximum spacecraft mass at launch 13.0 metric

tons. Minimum crew 3. I have a spreadsheet model already

constructed for this purpose, which I

proceeded to run again for these exact numbers.

Masses for the dry weights of capsule and trunk (before modification)

are my best guesses, but their sum

matches published data.

The modification is to install more tanks of NTO-MMH

propellants in the trunk, to a maximum

of the 3000 kg quoted cargo capacity for that trunk. I estimated propellant-tank mass split as

95-5 or a 19:1 ratio, same as for the

landers. I did not estimate

volumes, although there are 14 cubic

meters available in the trunk for this.

Results That Bound

the Design

These are shown in Figure 4.

Payload mass is limited more by the 13.00 ton thrown weight than the

1.35-1.4 km/s delta-vee requirement. That

payload mass is 1760 kg.

The per person allotment we used for the lander was 200 kg

person-plus-suit, and 100 kg of packed life

support supplies. The life support

supplies are probably a bit of an overkill,

so 1760 kg ~ 1800 kg, and 1800 kg

/ 300 kg/person is crew = 6 max.

Slightly less actually. Call

it no more than 5 crew at a time, plus

life support supplies, and no more than

about 150 kg of equipment or cargo in the capsule with them, for the trip to the moon.

Having the extra delta-vee means we can carry 6 crew, even 7,

home. That is a good safety

bonus. Crew Dragon is supposedly rated

for the same cargo home as cargo Dragon (3000 kg), so we are well within that limit.

This was accomplished by adding 2800 kg propellants to the

trunk, which also adds 147 kg of tank

inerts to the trunk inert weight. That

leaves a smidge for any extra plumbing before we hit the 3000 kg limit.

Figure 4 – Modifying Crew Dragon Into Lunar Orbit Dragon for

Falcon-Heavy Launch

Final Remarks

With these two bounding analyses, I have shown how it is possible to ship

13-ton lunar cargo and crew landers to the lunar orbit with Falcon-Heavy as the

launch rocket. I have also shown how it

is possible to ship crews to lunar orbit with the same rocket and a 13 ton

modified crew Dragon that has 2.8 extra tons of propellant in its trunk, connected to the Super Draco thruster systems

in the capsule.

The cargo landers deliver slightly over 5.3 tons to the

surface. The crew landers have a 5.3 ton

ascent stage that could carry as many as 6 crew back to lunar orbit.

At only $17M/delivered ton,

building a practical small experiment station that is permanently

occupied becomes easily possible, at a

price far below what was experienced doing the Apollo “flag-and-footprints”

stuff during the cold war.

What makes this feasible is a heavy lift rocket of adequate

size to put 13-ton payloads into lunar orbit,

and at a commercial launcher’s far lower price. This is true flying the rockets

fully-expendably. This capability should

become available within the next 1-2 years.

All that is needed from a vehicle development standpoint is

the two versions of the lander designed to these bounding limits, and then developed and made ready for

use. These share a common descent

stage. That should help lower costs and

development time.

Adding propellant capacity to crewed Dragon with tankage in

the trunk is not so much development work,

more of a routine modification that can be tested all-up in Earth

orbit, to make it ready to use.

We’ll need a 2 or 3 seat open electric rover car that weighs

no more than a ton. Between the Apollo

rovers and the recent Mars robot rovers,

this should not be a major development item.

Development,

yes, just not a “biggie”. Same for a 2-ton electric front-end

loader.

The hardest nut to crack is a surface habitat that can be

assembled from modules that fit within the 5 ton lander payload capacity, and that can be erected by men on foot in

spacesuits with hand tools. The idea is

to assemble it in an excavation done with the front end loader, and then bury it at least partially with that

front end loader.

This is the kind of thing that could be done within 1 or 2

presidential terms, which would net

returns orders of magnitude greater than Apollo, for costs orders of magnitude less than

Apollo.

Great analysis! It sounds promising for lunar missions in the near future.

ReplyDeleteI think the 5-ton module problem can be solved by using inflatable sections that can be joined together end-to-end to create habitats. They can then be layered with insulation and covered in dirt for protection against the sun and radiation.

Well there is a 3.7*10m second stage tank in the same LLO. Surely somewhere there has been a sugestion to use those as habitats.

Delete