Update

23 March 2024:

For the readers of this and other similar articles about ramjet

propulsion, be aware that GW’s ramjet

book is finally available as a self-published item. Its title is “A Practical Guide to Ramjet

Propulsion”. Right now, contact GW at gwj5886@gmail.com to buy your copy.

He will, upon receipt of payment by surface mail or Western

Union (or similar), manually email the

book to you as pdf files. This will take

place as 9 emails, each with 3 files

attached, for a total of 27 files (1 for

the up-front stuff, 1 each for 22

chapters, and 1 each for 4

appendices). The base price is

$100, to which $6.25 of Texas sales tax

must be added, for an invoice total of

$106.25.

This

procedure will get replaced with a secure automated web site, that can take credit cards, and automatically send the book as

files. However, that option is not yet available. Watch this space for the announcement when it

is.

GW is working

on a second edition. No projections yet

for when that will become available.

--------------

In November 1993, I

gave a paper on the title topic at the JANNAF (Joint Army Navy Nasa Air Force) meeting

held at the Naval Postgraduate School in Monterrey, California.

It was an unclassified paper given at a classified session at that

meeting. It raised quite a stir.

The topic of this paper was threefold:

(1) documenting the engineering design analysis model for a

gas generator-fed ramjet with an unchoked gas generator, that was capable of evaluating multiple

influences, to include variable throat

area,

(2) experimental ground tests that verified the engineering

design analysis model, and

(3) mission predictions evaluating this “unchoked throttle”

in a gas generator-fed ramjet propulsion system for an AMRAAM missile, plus variable drag as candidate means to

improve the throttling control.

This was work I did at what was then Rocketdyne/Hercules in

McGregor, Texas, ably assisted by Venton A. Kocurek. Unfortunately, my friend and colleague Venton is now

deceased, but he was a listed author on

the paper that I presented. That paper

is Ref. 1.

I literally photographed the figures in my hard copy of the

original presentation, to produce most

of the figures presented herein. There

was no other readily-available way to digitize them.

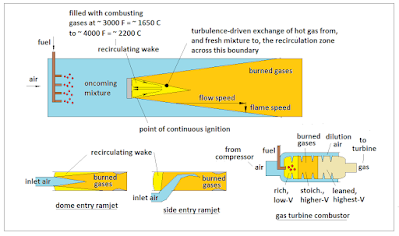

Background

In most gas generator-fed ramjet designs, the gas generator is a solid propellant

device that is fuel-rich in formulation,

with a choked exit, meaning the

flow is sonic at the minimum area of that exit.

For more details, see Refs. 2, 3, and

4.

These designs may be fixed flow, or flow to a fixed delivery history set by

the propellant grain design, or else

they can be reliably throttled by varying the choked area of the sonic exit, per Ref. 5. As it turned out, attempting to vary the propellant effective

burn rate by means of mechanically-extracted wires proved to be unreliable in

test. That concept was tested at another

contractor. The variable-area

valve, in the form of a pintle

valve, was invented at

Rocketdyne/Hercules. I played a key role

in that.

The alternative throttle approach described here is to

let the gas generator exit run unchoked,

so that the ramjet engine chamber pressure essentially drives the propellant

burn rate inside the gas generator chamber. If the solid propellant ballistic

characteristics and generator exit design are correct, this can approximate constant fuel/air ratio

control quite well, regardless of the absolute

level of the engine airflow. This has

distinct advantages for systems that must fly from low to high altitudes, and it does this with no moving parts or

control systems. Fuel regulation is

limited, but inherent to the design.

This technique was demonstrated by the French in flight test

(see Ref. 6), but was not pursued

by them, as they did not have fuel

propellants of the required ballistic characteristics (namely burn rate

exponents near unity). We did have

appropriate propellants at Rocketdyne/Hercules,

and I pursued this into extensive testing, on company independent research and

development (IR&D) funds, in full

scale engine hardware, using short-burn

gas generators based on convenient lab motor hardware.

After the JANNAF paper,

we continued testing of various fuel propellants in the

unchoked-generator hardware set on IR&D.

We found it to be a safer test method for experimental propellants than

the usual choked generator, because the unchoked

generator is essentially a “strand bomb” at only the limited engine

pressure. Many such fuel candidates were

tested this way, including a

highly-metallized boron formulation, and

a completely non-metallized “clean fuel” that met NATO min smoke criteria.

The generator effluent stream is the fuel to be burned with

air in the ramjet chamber just downstream.

This offers the potential of the far-higher specific impulse of the

airbreathing ramjet, while

simultaneously offering the “wooden round” simplicity and reliability of the

solid. Given some sort of fuel rate control

to the right fuel/air ratio, this

potential can be achieved across a variety of missions.

Fixed and fixed-delivery designs suffer when flying to high

altitudes. Choked-throttle designs offer

some altitude capability at the cost of propellant load displaced by the volume

of the throttle. The unchoked-throttle

approach offers high altitude capability without any fuel volume displacement

by a throttle valve. However, it is not an arbitrary-command throttle

technique, which the choked throttle

valve is.

There is a very strong effect of both fuel propellant

formulation and ramjet chamber flameholding flowfield geometry, upon achieved combustion efficiencies, as described in Ref. 7. For the IR&D effort, I used single center port fuel injection into

an asymmetric twin inlet geometry. If

choked, the port was small. If unchoked,

the port was large. Results are

thus comparable for both choked and unchoked tests, despite the slightly non-optimal injection geometry. The heavyweight lab motor as a short-burn gas

generator was very convenient, and I was

often able to use the full size flight-like combustors twice, before refurbishment! (The IR&D tests included testing

experimental insulations, too.)

Engineering Design Analysis of Unchoked Generators

The simplest design analysis model makes generator fuel flow

proportional to ramjet chamber pressure raised to the fuel propellant’s burn

rate exponent. This model includes the

assumptions that (1) burning surface is a constant, that (2) there are no soak temperature

effects upon burn rate, and that (3) changes

in ramjet chamber pressure do not affect the speed in the injection port. Those are generally bad assumptions, as all of these are first-order effects.

The next simplest model makes the fuel propellant burn rate

proportional to ramjet chamber pressure raised to the fuel propellant burn rate

exponent, but allows a variable burning

surface. This still neglects soak

temperature and port speed effects. Both

of those are first order effects.

The model presented in the JANNAF paper, which I devised, avoids these difficulties. It only presumes a convergent-only

approach to the min port area.

Further, the ramjet pressure is

the actual forward-dome static pressure where the fuel jet enters, not some other measure of ramjet chamber

pressure. This matches the subsonic jet

condition that jet pressure equals surrounding pressure. See Fig. 1.

It does not presume constant speed through the port, nor does it presume anything about the fuel

propellant burning surface or propellant grain temperature soak-out effects

upon burn rate. It even includes the

effects of generator chamber c* velocity,

which reflects gas generator flame temperature and (effective) gas properties. This model even includes transient c*

efficiency effects.

There are 3 things to worry about: (1) the propellant grain flow rate, (2) the port flow rate, and (3) other relevant relationships. The “other relevant relationships” are how

you tie together the propellant grain and subsonic port models. Each is detailed here, resulting in a final expression for fuel flow

rate as a function of ramjet chamber forward dome pressure.

Figure 1 – Image of Presentation Chart Showing the Situation

to be Modeled

Propellant

grain flow rate

The propellant grain flow rate wf is a function

of gas generator expulsion efficiency ηexp, burning surface S, propellant density ρ, and the power law describing burn rate versus

chamber pressure r = a PGn. That relationship is normally expressed as wf

= ρ

ηexp S a PGn. The factor “a” in the burning rate law

is also a function of the propellant soak-out temperature.

If we let G = ρ ηexp S, and we let e = (PG/P3)n

= (1 + 0.5*(γ

– 1)*Mp2)exp where exp = n γ/(γ –

1), and where Mp is the port

Mach number and γ the specific heat ratio of the gas generator effluent

stream, then we have wf = G a

e P3n. Note that “a”

scales as fT = exp[σp(T – Tref)]

to model grain soak-out temperature T:

a-at-T = a-at-Tref * fT. Tref is usually taken to be 77 F =

25 C, and fuel-rich propellant σp

usually falls in the 0.2%/F = 0.002/F range,

sometimes a bit higher. (Fully

oxidized σP

is usually about half that value.)

Port

flow rate

The port flow rate into the ramjet combustor is wf

= ρP

VP Ap, where ρP

and VP are the density and velocity at the minimum port area AP, and the Mach number Mp in that

port is subsonic, which also implies Pjet

= P3. We presume that ideal

gas compressible flow considerations apply at specific heat ratio γ, for the density vs pressure and

temperature, and also for the

speed-of-sound. Speed-of-sound is for the

velocity versus Mach number relationship.

The empirical characteristic velocity c* includes both

achieved chamber temperature and effective chamber gas properties, and there is a time-dependent scaling factor

on c* that is denoted by η*, which can model

the start-up effects of low free volume and cold surfaces. The empirical steady-state c* is best

determined from motor tests at various pressures, and is modeled as another power law c* = K PGm. For fuel-rich propellants, m usually falls in the 0.01 to 0.10

range, larger than for fully-oxidized.

Thus, including the start-up

effects, c* = η* K PGm.

Now, we let d be a

particular Mach number function as d = (1/Mp)*(1 + 0.5*(γ –

1)*Mp2)exp,

where exp = m γ / (γ – 1) – 0.5.

And, we let B = gc {[(γ +

1)/2]exp}0.5 where exp = (γ + 1)/(γ – 1). Under these definitions, the port massflow expression becomes wf

= [P3(1-m) Ap B]/[η* K d]. See

the third consideration for more definitions.

Other

relevant relationships

The normal power law for propellant burn rate is r = a PGn. Be aware that when plotting burn rate r

versus chamber pressure PG on a log-log plot, the slope of the line is the exponent n. There may be different values of n (and

therefore “a”) that apply in different regimes of PG. Be aware that “a” also scales by fT very nonlinearly with grain soak-out

temperature, as already indicated.

From theory, the

characteristic c* velocity is a function of achieved chamber temperature TG

and gas properties. The usual equation

is c* = {[gc RP TG / γ][0.5*(γ + 1)]exp}0.5,

where exp = (γ + 1)/(γ – 1). RP is the gas constant Runiv/MW. This is normally applied to choked nozzles as

wf = PG CD At gc /

c*. But with an appropriate port Mach

number function (d as described above),

it can be used for unchoked ports.

For a subsonic jet issuing from the fuel port, the static pressure in the jet Pjet

must equal the surrounding static pressure P3. Thus Pjet = P3. The d function then gets you from PG

to Pjet which is P3.

We now define flow function f to be the product of flow

function e from the grain massflow, and

flow function d from the port massflow.

Thus f = de = (1/Mp)*(1 + 0.5*(γ – 1)*Mp2)exp, where exp = (n + m) γ / (γ – 1) – 0.5. We also define factor H to be H = a K, at any given soak-out temperature. That is how the grain and port models are

tied together.

Overall

Unchoked Flow Rate Relationship

Combining the information from these three sources, the overall port flow function is

G H f η* = P3(1-n-m) AP B

which determines MP via f from any given

value of P3. G, H, AP, and B are constants for any given

mission, as are n and m. Finding MP from f is a

transcendental (or numerical interpolation) solution. Once MP is known, e can be found, and the grain flow equation yields wf

for any value of P3:

wf = G a e P3n

The overall propulsion balance of wf versus P3

in an actual engine is iterative, since

the value of P3 depends upon both the value of the captured airflow, and the delivered fuel flow (as well as the

air total temperature). But for

ground test approximation purposes, the

iterative balance need not be calculated,

since test airflow is fixed by intent.

For that, one plots combustor

fuel flow rates versus calculated P3 values at the test total

temperature, parametric upon inputs for

air flow rate and mixture ratio. Then

one calculates fuel flow out of the generator as a function of assumed P3

values, parametric upon burning surface

and soak temperature (if applicable).

These are superposed on the same plot.

Any proper ramjet cycle code can be used to compute a map of

fuel flow rate wf versus P3 for a given value of air total

temperature Tt2, parametric

upon both air flow wa and fuel/air ratio (or equivalence ratio φ), as shown in Fig. 2. This creates a sort of carpet-plot map.

Figure 2 – Image of Presentation Chart Showing Superposed

Ramjet Map and Generator Flow Lines

These gas generator relationships as described herein can

define fuel flow rate versus the same P3 values as are listed for

the ramjet map, without any iteration to

balance P3 in the ramjet engine.

At any given airflow (and air temperature), where the engine and gas generator wf

curves cross, is where the system will

equilibriate. You just

interpolate the P3 and mixture ratio values expected for the test. Mixture

ratio is an output, not an input, in this scenario. The figure shows that, as well. This presentation approach is something I

devised. It worked rather well.

What is important here is the shape and slope of the

generator fuel flow rate curves versus P3. If the propellant burn rate exponent is exactly

unity, these will be straight lines versus

P3. THAT is exactly-constant

fuel/air ratio operation, which is

exactly constant-φ operation,

regardless of the airflow (and air temperature). A high burn rate exponent very near unity

(above or below!) will therefore approximate constant fuel/air ratio control

quite closely. A low fuel propellant

exponent will not, and fuel/air ratio

will thus vary as airflow varies.

Stability

The first thing I did with this model was to check the sensitivities

of the equilibrium point mixture ratio to changes in various design

parameters. I looked at the effects of

burn rate, port area size, and inlet air total temperature, and plotted these at two different values of

design port Mach number. The design

point was 9.2 lbm/sec air at 800 R, with

an equivalence ratio near 1, meaning

stoichiometric. Results are given in Fig.

3. This is a plot of equivalence

ratio versus percent change in each parameter.

There is a plot at the low port Mach number, and another at the higher port Mach

number.

Figure 3 – Image of Presentation Chart Showing Sensitivity

of Equivalence Ratio to Various Parameters

The influence of burn rate is very strong indeed, as evidenced by the very large slopes on the

plots associated with it. Burning

surface, though not plotted, would have a similar large effect. The product of burn rate coefficient and

burning surface area is in the G factor of the model.

Air total temperature has a much weaker effect, reflected in its modest slope. This is true for both the lower and higher

port Mach numbers.

The design port area has a small effect (low slope) at the

lower port Mach number, but a much more

pronounced effect (steeper slope) at the higher port Mach number. At first glance that would seem to suggest

that a variable port area mechanism might be used to compensate for soak-out

changes to burn rate, and also to

compensate for burning surface variations as the propellant web burns. All that would be required to make this

possible, is designing to a high

subsonic port Mach number instead of a very low subsonic port Mach number.

As seductive as that notion was, due diligence required that I verify motor

stability. Choked motors are notoriously

unstable if burn rate exponent approaches unity too closely. For the unchoked generator, we want a burn rate exponent very close to

unity, or even somewhat greater than

unity.

For a conventional choked motor, the chamber pressure PG drives

both grain massflow, and massflow

through the nozzle. You simply plot the

massflow versus pressure curves for the grain and the nozzle onto the same

plot. Where the curves cross is the

operating point. The slope of the

nozzle massflow curve needs to be greater than that of the grain massflow curve, at that operating point, in order for the motor to be stable.

In that stable case, an

upward excursion in pressure takes the choked motor to a point where the nozzle

massflow is larger than the grain massflow.

That acts to drain the chamber and reduce its pressure back toward

equilibrium. A similar argument prevails

for a downward excursion in pressure:

the grain massflow is larger than the nozzle massflow. That acts to fill the chamber and raise its

pressure back toward equilibrium. THAT

is the choked motor stability argument in a nutshell.

For the unchoked port,

both pressures PG and P3 are important, but the backpressure P3 actually

drives the system, since their ratio is

determined by the port Mach number MP. The most direct analog to the choked motor

stability plot is the grain massflow and port massflow versus P3. The same slope ratio consideration

applies for stability: the slope of the

port massflow curve needs to exceed the grain massflow curve at the design

point where the curves cross.

Because the ratio of the two pressures is controlled by the

value of MP, an alternative

format for the stability plot is grain and port massflows plotted versus MP

instead. Because I wanted to investigate

whether a low or high value of subsonic MP can be used safely, that format was selected here.

The propellant used for this investigation was LPH-258, an early version of a choked-generator throttling

fuel, of which some mixes showed a lower

exponent in the very low pressure range,

a higher exponent in an intermediate range, and a lower exponent in the high range of

pressures. This particular mix tested as

having an exponent greater than unity in that intermediate range.

Plots of grain and port massflow versus MP were

made for the low range of pressures and the intermediate range, where it was anticipated that unchoked test

articles might be operated. The

breakpoint between those pressure ranges was at PG = 65 psia for

this mix of propellant. Those plots are

given in Fig. 4.

On the left hand plot,

where exponent is less than unity,

the slope of the nozzle massflow is larger than the slope of the grain

massflow at the indicated operating point where the curves cross, where port Mach number is roughly MP

= 0.7. This indicates stable operation

with this propellant is feasible at higher subsonic MP, when operating in the low range of P3

and PG.

On the right hand plot,

where the exponent is greater than unity, there are actually two curve crossings, indicating two candidate operating

points, one near MP =

0.7, the other nearer MP =

0.95. The nozzle curve slope is greater

than the grain massflow curve at the lower MP, but the reverse is true at the upper MP! That upper point is unstable, and is so close to choking, that the generator could easily and

spontaneously choke and explode! The

stable lower point is just not that far away from the upper unstable

point. A sufficient disturbance (like a sudden

P3 drop for any reason) could drive the motor to the instable condition, whereupon it might explode.

Figure 4 – Image of the Presentation Chart Showing Unchoked

Stability Plots For 2 Regimes of Exponent

The lessons here were rather clear. First, you want lower values of subsonic MP, most especially when the exponent is near or

exceeds unity. Second, to maximize the stability margin at that

lower stable operating point, you need

to design for very low values of MP indeed, closer to 0.1 than 0.5. Third, that low MP design choice makes

modulating AP unattractive for compensating burn rate, soak-out,

or burning surface variations, precisely

because the sensitivity to that variable is going to be so low.

Short-Burn Full-Scale Ground Tests

The test hardware is shown in Fig. 5, along with some data on the first four successful

live-burn tests conducted in it. The gas

generator was a standard 6-inch heavyweight lab motor with one or two

cartridge-loaded internal burning propellant grains. The inlet and combustor rig was

full-scale, flight-like hardware

borrowed from the contract VFDR (variable-flow ducted rocket, being a choked, valve-controlled gas generator-fed ramjet) program, and insulated on IR&D.

The lab motor is coupled to the combustor with a custom

adapter forward dome that was fabricated on IR&D. It was detail-designed by my friend and

colleague Jerry Lammert. The big

injector tube in the figure was only used once, on the very first test, which resulted in a “no-burn” (airbreathing

ignition failure) in the ramjet. After

that, the big injector tube was deleted

from the test rig.

The direct-connect test facility at Rocketdyne/Hercules by

this date had 20 lbm/sec airflow capability at up to 1660 R total

temperature. It used two 10 lbm/sec

lines that used pebble bed heaters, one capable

of 1210 R, the other capable of 1660

R. These tests were run at open-air

nozzle conditions, although the facility

had high altitude capability by means of a supersonic diffuser plus a steam

ejector.

Figure 5 – Image of the Presentation Chart Showing Test

Hardware and Initial Tests to be Run

Venton Kocurek was still a fairly recent hire at that

time, and I “broke him in” on ramjet

work planning for these tests and reducing the data afterward. Plus,

we did some of the “dirty-fingernails” test article assembly and

post-test disassembly work together.

The very first test run in this configuration was a no-burn

run with a propellant designated LPH-563A.

However, even though no ramjet

combustion was obtained, we did

demonstrate that the fuel flow followed the airflow variations in this unchoked

generator mode. That data is given in Fig.

6.

The left panel shows plots versus time for the pressure at

the air metering venturi, and the combustor

P3 response. The right panel

shows the traces versus time for combustor P3 and generator PG. It is quite clear that the fuel tracked the

air, in a fair approximation to constant

fuel/air ratio.

The no-burn on that very first test was attributed to the

fuel injector. The proof: after its deletion, we never had any trouble again, lighting the ramjet combustor, with any of the fuels tested.

Figure 6 – Image of the Presentation Chart Showing Unchoked

Fuel Control in a No-Burn Test

Subsequent to the 4 live-fire tests presented at the JANNAF

meeting, a series of experimental fuels

was tested in this same hardware set, as

full-scale, short-burn tests. Some of those were unchoked with graphite

nozzle inserts of very large diameter and internal-burning grains, others were choked with graphite insert

nozzles of very small diameter and end-burning grains. All were simple single-port dome injection on

centerline, which while not “tuned up” for

max performance, performed well enough

to see the correct trends among the experimental propellants.

Flight Predictions

I had Venton Kocurek modify an Air Force-supplied trajectory

program called ZTRAJ to correctly model the unchoked generator option. He was more of an expert at computer programs

than I was, and he was aware of my

full-blown unchoked analysis, which made

him the perfect choice. This was a large

effort that took some time, but Venton

did an outstanding job.

We did not use the full-blown, full-capability unchoked generator analytical

model for this. Instead, we used the intermediate model described

above, that essentially just makes fuel

flow a power function of P3,

using n as the exponent.

But, we added correction factors

for modeling variations in burning surface,

and for modeling the effects of soak-out temperature upon burn

rate. The actual changes to the code

were more complex than just that notion,

as is illustrated in Fig. 7.

Figure 7 – Image of the Presentation Chart Showing the

Modifications to the ZTRAJ Code

We already had the ZTRAJ computer model for the throttled

ducted rocket ramjet, here designated

TDR. We had the data for the fixed-flow

ducted rocket ramjet, designated

FFDR, and so we easily set up a computer

model of it. I sized an unchoked

generator propulsion scheme for these same basic missile models, termed “backpressure rate control” or BRC. My as-sized BRC is shown in Fig. 8. The as-sized TDR and FFDR are shown in Fig.

9. A comparison of sizepoint data

among the 3 designs is given in Fig. 10.

All three were sized using the same low-percentage boron fuel, thus entirely removing fuel characteristics

as a variable, from the fuel management

and performance comparison.

These vehicles size quite differently, because of their quite-different propulsion

characteristics. The FFDR sizes at cold

takeover, cold-soaked, where it runs the leanest. It has to meet Air Force-specified thrust

margins, at a min takeover speed

supplied by the integral (nozzleless) booster.

It has to meet an inlet pressure margin specification at sizing. At warmer conditions, it has more-than-minimum thrust margin, and runs richer in mixture. This enrichment reduces its takeover thrust

margin again, when soaked out hot, because it runs over-rich, which in turn reduces performance once again.

The TDR sizes at the hot takeover conditions, soaked out hot. It has to meet min thrust margin requirements

soaked out hot, and also an inlet

pressure margin. It exceeds thrust

requirements at colder conditions,

because its mixture ratio is under full control with the throttle valve

system.

The BRC was sized at its shock-on-lip Mach number, hot soaked on a hot day, at max tolerable mixture. Thrust margin was maximized at this

condition. For all 3 propulsion systems, inlet size was constant, only the ramjet throat area A5 was

revised to match-up the engine balance in the sizing.

Figure 8 – Image of the Presentation Chart Showing the

As-Sized BRC Missile

Figure 9 – Image of the Presentation Chart Showing the

As-Sized TDR and FFDR Missiles

Figure 10 – Image of the Presentation Chart Showing

Sizepoint Data Variations for All 3 Missiles

There are 4 plots in Figure 10. Upper left is thrust margin versus soak-out

temperature at min takeover speed.

Lower left is equivalence ratio vs soak temperature. Equivalence ratio is a measure of mixture

strength: 1 is stoichiometric, greater than 1 is fuel-rich, less than 1 is lean. Upper right is inlet pressure margin data

versus soak temperature. These need to

stay positive, and they do. Lower right is a normalized specific impulse

versus soakout. These data were

normalized to stay unclassified, and

probably need to remain so for ITAR (international traffic in arms regulation) reasons.

The BRC generally falls intermediate in min takeover performance values between

the TDR and the FFDR.

The missions chosen for evaluation were co-altitude head-on

engagements, with the launch aircraft

and the target both flying at Mach 0.9.

Standard day conditions were presumed.

Upon seeing the launch, the

target turns 180 degrees and accelerates rapidly at thrust/weight = 1 to Mach

1.5 as an attempt to get away,

converting the engagement to a tail chase. This was evaluated at 20,000 feet with the

target making his turn at 9 gees, and at

40,000 feet with the target making his turn at 4 gees in the thinner air.

Missile engagement limitations were intercept Mach 2.26 at

33 gees at 20,000 feet, and intercept

Mach 2.60 at 18 gees at 40,000 feet in the thinner air. To be a hit,

miss distance had to be no more than 10 feet. See Fig. 11.

These computer simulations were run with our modified ZTRAJ

code, by Venton Kocurek under my

guidance. The code already had fuel

control options to model the FFDR and the TDR.

By adding the BRC to it, we could

do this comparative study.

What results are of interest are F-pole versus launch

range, and intercept Mach versus launch

range, plotted for several different

launch ranges (each launch range its own computer run). End of mission could be propulsion limited

(out-of-propellant and coasting down) or time-limited (battery life for the

guidance). Launch range is self explanatory, being the horizontal separation distance between

the two aircraft when the missile is launched.

F-pole is the slant range between launch aircraft and target at the time

the missile intercepts the target. It is related to something called an “F-pole

turn” by the combat pilots.

The TDR, BRC, and FFDR missiles (as I sized them) were

evaluated on these missions. The Air

Force asked us to include some dive brake “drag flippers” on the BRC, to determine if drag modulation might be a

better way to help manage the fuel supply in the BRC. These brakes would “trigger” at a set speed, to keep the vehicle flying slower, thus hopefully conserving fuel. The Air Force suggested that we use a 3500

feet per second trigger speed. Initial

runs were made using that suggested trigger speed.

Figure 11 – Image of the Presentation Chart Showing the Two

Missions Used For Evaluation

Results for the two altitudes in terms of F-pole versus

launch range are given in Fig. 12.

Results for intercept Mach versus launch range are given in Fig. 13. These results were normalized to avoid

classification, and probably should

remain normalized because of ITAR.

At the low altitude,

there was little difference in the F-pole performance versus launch

range among all the configurations. The

TDR did the best, the BRC

intermediate, and the FFDR the least. Drag flippers on the BRC made very little

difference, as the missile just barely

reached the trigger speed.

The story at the high altitude was similar, except that there was a significant shortfall

of F-pole performance of the FFDR relative to the TDR. The BRC was intermediate, but very nearly as good as the TDR. Here, the

drag flipper trigger speed was never reached by the BRC missiles at all, so there is no difference traceable to it.

Figure 12 – Image of the Presentation Chart Showing F-Pole

Results

For the intercept Mach versus launch range results, the story is still quite similar. The spread between TDR and FFDR is almost

zero at the lower altitude, but

considerable at the high altitude.

At the low altitude, the BRC does a little worse than the

FFDR, but only just a little. The drag flippers made very little

difference, with the drag flipper BRC

very slightly worse than the plain BRC.

At the high altitude,

the BRC configurations both did almost as well as the TDR, and much better than the FFDR. The drag flippers made no difference, not being triggered at all on this

mission.

Figure 13 – Image of the Presentation Chart Showing

Intercept Mach Results

At this point, we

re-ran only the BRC, with and without

the drag flippers, on only the 40,000

foot mission. The only change was

lowering the drag flipper trigger speed to 3100 ft/sec, so that they would trigger over a more significant

portion of the mission.

The results of this revision are given in Fig. 14. This shows only intercept Mach versus launch

range, and that for only the two BRC

configurations.

There is a significant difference between the plain BRC and

the BRC with the drag flippers. The

plain BRC simply does far better. It has

higher intercept speeds at longer launch ranges.

Apparently, the fuel

that might have been saved by slowing down,

instead gets eaten-up overcoming the extra drag, and then some. Therefore,

drag modulation is just not very attractive as a means to improve the

fuel regulation in the BRC propulsion scheme.

We already know the BRC design responds weakly to port area

modulation, because stability margins

demand very low port Mach numbers at very large port diameters.

It would appear that designs featuring as low a propellant

burn rate sensitivity σP as possible, and as neutral a surface-web trace as

possible, is the best route for further

development of BRC propulsion.

These results were communicated to the Air Force before the

JANNAF presentation was made.

Figure 14 – Image of the Presentation Chart Showing

Intercept Mach at Higher Altitude and Lower Trigger Speed

Final Remarks

Further tests of experimental fuel propellants were made in

this short-burn test hardware, but not

in time for the JANNAF presentation.

These tests are well-described in Refs. 4 and 7, including some color photography from those

tests, plus there was a propellant

“shoot-off” on the contract VFDR program.

The two low-percentage boron fuels reported in the JANNAF presentation

were part of that “shoot-off”, along

with a high-metal boron-titanium propellant,

and a non-metallized “clean fuel” that met NATO min smoke criteria, despite being oxidized with ammonium

perchlorate. I developed both of those

very rapidly on IR&D, using these

short-burn test methods and hardware. The contract “shootoff” verified that all four

of those IR&D fuels were every bit as good as the two contract fuel

propellants.

The problem of achieving low propellant burn rate

temperature sensitivity had been addressed earlier on IR&D, and on the contract VFDR programs, with something called the “strand augmented

end burner” (SAEB). Those gas generators

on the contract programs were end burners,

fitted with a throttle valve. The

SAEB version used LPH-563A fuel rich matrix propellant, with a fully-oxidized strand propellant using

the same binder system. The plain end

burner used LPH-453 propellant, which

had been developed from the much earlier LPH-258 formulation that I tested

unchoked on IR&D.

By fitting such grains with fully-oxidized propellant

strands that had burn rates always higher than the majority fuel-rich matrix

propellant, we divorced the burn rate

ballistics from the fuel effluent characteristics that we needed. The strands had half or less the temperature

sensitivity of the matrix fuel propellant.

That allowed more of the valve area turndown to address fuel rate

turndown for high altitude, instead of

compensating for temperature sensitivity. See Fig. 15 for an image of the SAEB.

Figure 15 – The End-Burning Dual-Propellant SAEB Design

Designs like the FFDR could feature either end-burning or

internal-burning grain designs, using

high intrinsic burn rates in the end-burners, and low intrinsic burn rates in the

internal-burners, just all at high

chamber pressures. The end burners have

slightly-higher cross-sectional loadings.

There is no propellant displacement by a throttle valve or its

interstage in the FFDR.

The BRC featured internal-burning grain designs using high intrinsic

burn rates, just at very low chamber

pressures where the actual burn rate is low.

To solve the propellant burn rate temperature sensitivity issue, we needed a similar two-propellant solution

for the internal-burning designs.

On IR&D, I had my

friend and colleague W. Ted Brooks develop a model for such a device. He named it the “circumferentially-augmented

radial burner” (CARB). Ted Brooks (now

deceased) was my mentor in internal ballistics when I was a young

engineer, and he wrote the NASA

monograph on internal ballistics (Ref. 8).

I believe the CARB would have worked very well, but we never got to test it. See Fig. 16 for an image of the CARB

design.

Figure 16 – The Internal-Burning Dual-Propellant CARB Grain

Design

All of these gas generator designs use case-bonded grain

technology, but must survive cold soak

to -65 F without cracking the propellant or peeling its bond away from the

case. End-burning designs are the worst

offenders in this respect, but some high

cross sectional-loading internal burners also suffer. Solid elastomer internal case insulation is

just not compliant enough to do that job.

At Rocketdyne/Hercules, we

invented something called the stress-relieving liner that was compliant enough

to serve this function successfully. See

Fig. 17.

Figure 17 – The Stress-Relieving Liner Design That Supports

End-Burners and Other Designs

As an aside,

the integral booster shown above for the 3 configurations analyzed above

was a “nozzleless booster”. This used a

two-propellant overcast to minimize the losses otherwise inherent in a

nozzleless booster rocket, which ejects

no booster nozzle assembly or debris.

That design and those propellants were developed on IR&D and went to

the contract VFDR program for validation,

and they became the baseline.

That concept is illustrated in Fig. 18.

Figure 18 – The Dual-Cast Nozzleless Booster Concept

Right after the subject JANNAF presentation described here, the plant closure announcement was made. The following November (1994), I was laid off in the first wave of layoffs, being most closely associated with new

product IR&D work, not ongoing

contract work. That ended my career in

aerospace defense work, there being a

massive industry contraction underway, after

the fall of the Soviet Union.

The plant finally closed for good within another year (by late

1995). The sad tale of what happened to

the incredible gas generator-fed ramjet (and nozzleless booster) technologies

that we had, is covered by refs. 4, 5, and

7. All of that was lost! If the US military wants a ramjet missile of

AMRAAM class today, then they have to

buy the “Meteor” from the Europeans. It’s

a TDR type of gas generator-fed ramjet,

very similar to what we had.

Their valve geometry is a bit different,

but it is the same basic notion.

References

Most (but not all) of these references are articles posted

elsewhere on this site. The others can

be located by an internet search,

excepting possibly this particular JANNAF presentation (ref. 1), which is why I wrote this article. There is a catalogue of some related articles

that may be relevant, in Ref. 9.

To quickly find any of the articles on this site, you need the date and title to use in the

navigation tool, left side of this

page. Click first on the year, then the month, then on the title if need be (if multiple

articles were posted in that month).

Clicking on any figure in an article lets you see all the figures

enlarged. Top right is an X-out feature

that takes you right back to the article.

#1. Gary W. Johnson and Venton A. Kocurek, “Evaluation of Unchoked Generator Ducted

Rocket Ramjets”, paper given at the 1993

JANNAF meeting held at the Naval Postgraduate School, Monterrey,

CA, given November 17, 1993.

#2. Gary W. Johnson,

“Primer On Ramjets”, article

posted on http://exrocketman.blogspot.com, 10 December 2016.

#3. Gary W. Johnson,

“Ramjet Cycle Analyses”, article

posted on http://exrocketman.blogspot.com, 21 December 2012.

#4. Gary W. Johnson,

“The Ramjet I Worked On The Most”,

article posted on http://exrocketman.blogspot.com, 2 August 2021.

#5. Gary W.

Johnson, “Use of the Choked Pintle Valve

for a Solid Propellant Gas Generator Throttle”,

article posted on http://exrocketman.blogspot.com, 1 October 2021.

#6. Propulsion and Energetics Panel Working Group 22, “Experimental and Analytical Methods for the

Determination of Connected-Pipe Ramjet and Ducted Rocket Internal Performance”, AGARD Advisory Report 323, July 1994.

#7. Gary W.

Johnson, “Ramjet Flameholding”, article posted on http://exrocketman.blogspot.com, 3 March 2020.

#8. W. Ted Brooks, “Solid Propellant Grain Design and Internal

Ballistics”, NASA SP-8076, March 1972.

#9. G. W.

Johnson, “Lists of Some Articles By

Topic Area”, article posted on http://exrocketman.blogspot.com, 21 October 2021.

.jpg)

.jpg)