The problem is not so much propulsion as it is heat

protection. The reason has to do with

the enormous energies of high speed flight,

and with steady-state and transient heat transfer. Any good rocket can push you to hypersonic

speeds in the atmosphere. But it is

unlikely that you will survive very long there!

The flow field around most supersonic and hypersonic objects

looks somewhat like that in Figure 1.

There is a bow shock caused by the object parting the oncoming air

stream. Then, the flow re-expands back to near streamline

direction along the side of the object.

Then it over-expands around the aft edge, having to experience another shock wave to

straighten-out its direction parallel to free stream again. This aft flow field usually also features a

wake zone of one size or another, as

shown.

The conditions along the lateral side of the object are not

all that far from free stream, in terms

of static pressures, flow

velocities, and air static

temperatures. One can compute skin heat

transfer using those free-stream values as values at the edge of the local

boundary layer, and be “in the ballpark”. That is what I do here, for illustrative and conceptual

purposes.

Once flow is supersonic,

the boundary layer behavior isn’t so simple any more. There is a phenomenon that derives from the

very high kinetic energies that one simply does not see in subsonic flow: energy conservation. The value of that kinetic energy shows up as

the air total temperature Tt,

which is the upper bound for how hot things could be. Air captured on board by any means

will be very close to Tt, if

subsonic relative to the airframe after capture. This includes any “cooling air” one might use!

In addition, there is

“viscous dissipation”, which has the

effect of raising the actual (thermodynamic) temperature of the air in a max

shearing zone within that boundary layer, to very high temperatures. The peak of this temperature increase is

called the recovery temperature Tr.

The difference between this recovery temperature and the local skin

temperature Ts is what drives air friction heat transfer to the

skin, not the difference between the air

static temperature and the skin temperature,

as is typical in subsonic flow.

See Figure 2. The temperature

rise from static to recovery is around 88 to 89% of the rise from static to

total, in turbulent flow, which this almost always is.

Most heat transfer calculations for this kind of flow regime

take the basic form and sequence illustrated in Figure 3. “How high and how fast” determines the

conditions of flow, ultimately. Total and recovery temperatures may be

computed from this, and total

temperature is conserved throughout the flow field around the object, regardless of the shock and expansion

processes. The flow alongside the

lateral skin is not far from free-stream to first order, and that may be used to find out “what

ballpark we are playing in”. Better

local edge-of-boundary layer estimates must come from far more sophisticated

analyses, such as computer fluid

dynamics (CFD) codes.

In Figure 3, the

process starts by determining recovery temperature. The velocity,

density, and viscosity at the

edge of the boundary layer won’t be vastly different from free stream, unless you are really hypersonic, or really blunt (detached bow shock). The various correlations account for this.

Using whatever dimension is appropriate for the selected

heat transfer correlation, one computes

Reynolds number Re. Low densities at

high altitude lead to low values, and

vice versa. High speeds lead to high

values. Different correlations have the

density and viscosity (and thermal conductivity) evaluated in different ways

and at different reference temperatures.

You simply follow the procedure for the correlation you selected. Sometimes this is neither simple, nor straightforward.

The complexity of these correlations varies. My favored lateral skin correlations use a T*

for properties evaluation that is T* = mean film plus 22% of the stagnation

rise above static. My favored slower

than reentry stagnation zone correlation evaluates fluid properties at total

conditions behind a normal shock. In the

stagnation case, Reynolds number is

based on the pre-shock freestream velocity.

The next step is the correlation for Nusselt number Nu. This nearly always takes the form of a power

function of Re (plus some other nontrivial factors), usually with an exponent in the vicinity of

0.8 or so. Nusselt number is then

converted to heat transfer coefficient h,

using the appropriate dimension and the appropriately-evaluated thermal

conductivity of the air, for the

selected correlation.

The heat transfer rate is then as given in Figure 3, which shows the Tr – Ts

temperature difference.

One should note

that because both density (which is in Re) and thermal conductivity k (which is

in h) are low at high altitudes, the

computed values of h will be substantially smaller at high altitudes in the

thin air. High speeds act to raise

h, and to very dramatically raise Tr

and Tt. That last effect is

truly exponential.

Having the heat transfer rate is only part of the

problem. One must also worry about

transient vs steady-state effects. If

the skin is completely uncooled in any way,

it is then only a heat sink of finite capacity, with the convective input from Q/Aconv

= h (Tr - Ts). One

can use material masses and specific heats to estimate the heat that is sinkable

as skin temperature rises. The highest

it can reach is Tr = Ts,

where it is fully “soaked out” to the recovery temperature. That zeroes heat transfer to the skin.

The time it takes to soak out can be very crudely

estimated as 3 “time constants”,

where one “time constant” is the heat energy absorbed to soak-out all

the way from initial Ts to Tr, divided by the initial heat transfer rate

when the skin is at the initial low Ts.

More complex steady-state situations must find the

equilibriating Ts when there is convective input from air

friction, conductive/convective heat

transfer into the interior of the object (something not illustrated here), and re-radiation from the hot skin to the

environment. In high speed entry, there is also a radiative input to the skin

from the boundary layer itself, which is

an incandescent plasma at such speeds, and

this is very significant above about 10 km/s speeds.

Not covered here in the first two estimates are heat transfer correlations

for nose tips and leading edges.

Those heat transfer coefficients tend to be about an order of magnitude

higher than the coefficients one would estimate for “typical” lateral

skin. Stagnation soak-out temperatures

should really be nearer Ttot than Tr, although those temperatures are really very

little different.

Suffice it to say here that if one flies for hours instead

of scant minutes or seconds with uncooled skins, they will soak out rather close to the

recovery temperature Tr or total temperature Ttot. That brings up practical material

temperature limits. See Figures 4

and 5.

For almost all organic composites, the matrix degrades to structural uselessness

by the time it reaches around 200 F. The

fiber might (or might not) be good for more,

but without a matrix, it is

useless. For most aluminum alloys, structural strength has degraded to under 25%

of normal by the time it reaches about 300 F,

which is why no supersonic aircraft made of aluminum flies faster than

Mach 2 to 2.3 in the stratosphere, and

slower still at sea level. Dash speeds

higher are limited to several seconds.

Carbon steels and titaniums respond to temperature very similarly, it is a very serious mistake to think that

titanium is a higher-temperature material than carbon steel! Titanium is only lighter than

steel. And you “buy” that weight savings

at the cost of far less formability potential with titanium. Both materials are pretty-much structurally

“junk” beyond about 750 F. Various

stainless alloys have max recommended use temperatures between 1200 and 1600

F. Inconel is similar to the higher end at

about 1500 F. There are a very few “superalloys”

that can be used to about 2000 F, give

or take 100 F.

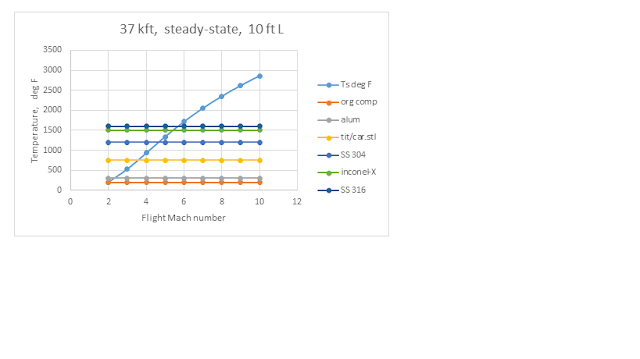

Figure 4 compares steady-state recovery (max soak-out) and

total temperatures to material limitations on a standard day at sea level. Max speed for organic composites are barely

over Mach 1, and just under Mach 2 with

aluminum. Steel and titanium are only

good to about Mach 2.5, unless cooled in

some way. Stainless steels can get you

to about Mach 3.5-to-4, the superalloys

not much higher.

Figure 4 – Compare Tt and Tr to

Material Limitations at Sea Level

Figure 5 -- Compare Tt and Tr to Material Limitations in the Stratosphere

One should note that stratospheric temperatures are only

-69.7 F from about 36,000 feet altitude to about 66,000 feet altitude. Above 66,000 feet, air temperatures rise again, to values intermediate between these two

figures! That lowers the speed

limitation some, for altitudes above

66,000 feet.

This steady-state soak-out temperature comparison neatly

explains why most ramjet missile designs (usually featuring shiny or

white-painted bare alloy stainless steel skin) have been limited to about Mach

4 in the stratosphere, and around Mach 3.3

or so at sea level. Those limitations on

speed are pretty close to the 1200 F isotherms of total or recovery

temperature. Without re-radiation

cooling, the skins soak out fairly

quickly (the leading edges and nose tips extremely quickly).

To fly faster will require cooled skins, or one-shot ablatives, or else the briefest episodes (scant seconds)

of transient flight. The

nose-tip and leading edge problem is even worse! That means for long-duration / long-range flight, the skin must be cooled, or else coated with a thick, heavy,

one-shot ablative. There

are two (and only two) ways to do cooling:

(1) backside heat removal, and

(2) re-radiation to the environment. Or

both!

Backside heat removal must address (1) conduction through

the materials, (2) some means of

removing the heat from the backside of the materials, and (3) some means of storing or disposing of

all the collected heat (what usually gets forgotten). Liquid backside cooling using the fuel comes

to mind, with the heat dumped in the

fuel tank. However, there are two very severe limits: (1) the liquid cooling materials and media

may not exceed the boiling temperature at tolerable pressures, and (2) the heat capacity of the fuel in the

tank is very finite, and decreasing

rapidly as the vehicle burns off its fuel load.

Re-radiation to the environment requires a very “black”

(highly emissive) surface coating, and

is further limited by the temperature of the environment to which the heat is

radiated. These processes follow a form

of the Stefan-Boltzmann Law, to

wit: Q/A = σ εs (Ts4

– Te4), where σ is

the Stefan-Boltzmann constant, and the εs

is spectrally-averaged material emissivity at the corresponding temperature. Subscript s refers to the hot radiating skin

panels, and subscript e refers to the

environment.

While deep space is ~4 K,

earth temperatures are nearer 300 K,

and that is what most atmospheric vehicles usually “see”. The material absorptivity is its

emissivity, which is why that value is also

used for the radiation received from the environment. A truly “black” hot metal skin might have an

emissivity near or above 0.8. This

could be achieved in some cases by a metallurgical coating or treatment, in others by a suitable black paint (usually one

of ceramic nature, and very high in

carbon content).

One More Limitation

to Consider

Once the boundary layer air is hot enough, it is no longer air, it is becoming an ionized plasma. The kinds of heat transfer calculations that

I used here become increasingly inaccurate when that happens, and other correlations developed for entry

from space need to be used instead. As a

rough rule-of-thumb, that limit is about

5000 F air temperature.

If you look at Figure 4 (sea level),

you hit the “not-air anymore” limitation starting around Mach 7. In figure 5 for coldest stratosphere, that limit gets exceeded starting around Mach

8. The only calculation methods

that “work” reliably above these limits would be CFD codes, and even then, only if the correct models and

correlations are built into the codes. That

last is not a given! “Garbage-in, garbage-out”.

That expression is no joke, it is

quite real.

With Re-Radiation

Cooling at Emissivity = 0.80

This applies only to lateral skins, not leading edges, because the heat transfer rates are an order

of magnitude higher for leading edges.

That effect alone changes the energy balance enormously.

But for lateral skins,

the speed limitation occurs when the re-radiation heat flow equals the

convective input to the skin. The

complicating factor is that convective heat transfer is a strong function of

altitude via the air density, while

re-radiation is entirely independent of altitude air density. There are now more variables at work on the

energy balance than just ambient air temperature.

That means two charts depicting the “typical” effects are

entirely inadequate. We need a sense for

how this changes with altitude air density.

What follows is a selection of equilibrium re-radiating temperature

versus speed plots, at various

altitudes, in a US 1962 Standard Day

atmosphere model. Material temperature

capabilities are superposed, as before.

Figure 11 – Lateral Skin Radiational Equilibrium at 110,000

feet

Tough Design Problem

How exactly one achieves this re-radiation cooling is quite

a difficult design problem. The skin

itself will be very hot, in order to

re-radiate effectively. Not only will it

be very structurally weak, there will be

heat leakage from it into the vehicle interior.

This is inherent, but by careful

design, can be limited to rather small (1-2%)

values compared to the energy incident and re-radiated from the outer

surface.

There must be a sufficient thickness of low density

insulation between that skin and the interior,

one capable of surviving at the skin temperature. This insulation must be some sort of mineral

fiber wool. There are no simple glasses

that survive at the temperatures of interest for hypersonic flight.

The mountings that hold the skin in place constitute

metallic conduction paths into the interior.

These must be made of serpentine shape,

of length significantly greater than the insulation thickness, in order to effectively limit heat leakage by

the metallic conduction path.

Finally, there is the

issue of sealing the structure against throughflow induced by the surface

pressure distribution relative to the pressure in the interior. Because it is much easier to design seals

that survive cold, than seals that

survive incandescently-hot, it seems

likely that the surface skins must be vented,

with the pressure distribution resisted by colder structures deeper

within the airframe.

Two Sample Cases

The SR-71 and its variants featured a “black”

titanium skin, cooled by

re-radiation, but nothing else. The leading edges (at least very locally)

would approach the soak-out temperature limits shown in Figures 4 and 5 above. Typical missions were flown at around 85,000

feet, with speeds up to, but not exceeding Mach 3.3. In the very slightly-colder air at 66,000

feet, that leading edge limit was Mach

3.5.

As figure 10 shows,

the lateral skins had a higher speed limit nearer Mach 4. So we can safely draw the rough conclusion that

the SR-71 airframe was likely limited by leading-edge heating to about Mach 3.5

or so, at something around 80,000 or

85,000 feet.

The X-15 featured skins of Inconel-X

that were radiationally very “black”. About

the max recommended material use temperature is 1500-1600 F. Leading edges might tend toward the local

soak-out limit at about Mach 4 to 4.5,

unless internally cooled by significant internal conduction toward the

lateral surfaces of a solid piece, which

these were. Thinner air “way up high”

might help with that balance, by

reducing both the stagnation, and

lateral, heating rates.

As shown in figure 11,

the re-radiation equilibrium limitation near 110,000 feet is closer to

Mach 10 for the lateral skins, and

higher still at higher altitudes, as the

other figures indicate by their trends.

The fastest flight had a white coating,

which effectively killed radiational cooling. For that,

the soak-out speed limit is closer to Mach 4.5 to 5.5, based upon figures 4 and 5.

Again, we might very crudely conclude the X-15

was limited by its leading edges to something between Mach 5 and Mach 10. The fastest flight actually flown reached

Mach 6.7, without any evident wing

leading edge or nose damage, excepting

some shock impingement heating damage in the tail section.

My Conclusions:

Most of the outfits claiming they have vehicle designs that

cruise steadily at Mach 8+ (high-hypersonic flight) have not done their thermal

protection designs yet.

That lack inherently means they do not have feasible vehicle

designs at all, since thermal protection

is the enabling item for sustained high-hypersonic flight.

“Hypersonic cruise” (meaning steady state cruise above Mach

4 or 5 for extended ranges) is therefore nothing but a buzz word, without an advanced thermal protection system

in place.

The faster the cruise speed,

the more advanced this thermal protection must be, and the more unlikely there will be a metallic solution.

Practical

Definitions:

Blunt vehicles = hypersonic Mach 3+

Sharp vehicles = hypersonic Mach 5+

Formally,

“hypersonic” is when the bow shock position relative to the vehicle

surface contour becomes insensitive to flight speed.

A Better Leading Edge

Model

That is entirely out of scope here. It might consist of one solid leading edge

piece, to be assumed isothermal. It would have a very small percentage of its

surface area calculated for stagnation heat transfer, with the remainder calculated as lateral skin

heat transfer, except as modified for

convexity into the flow near the leading edge.

There would be no conduction or convection into the interior. All surfaces would re-radiate to cool.

The next best model is a finite-element approximation, which allows for temperature variations and

internal conduction, within the leading

edge piece. Adding conduction and

convection paths into the interior is the next level of modeling fidelity. None of this is amenable to simple

hand calculation.

Supersonic Inlet

Structures

These are an even more difficult problem, as the inner surfaces are (1) blocked from

viewing the external environment for radiational cooling, and (2) are exposed to edge-of-boundary layer

conditions that are very far indeed from freestream conditions.

This is some amazing work. It was a very interesting read into aspects of hypersonic flight I hadn't put much thought into, as most discussions I know focus on things like propulsion and fuel efficiency.

ReplyDeleteI have a few questions:

-You mention that leading edges heat much more quickly than the sides. Could a simple leading edge to lateral skin cooling loop allow a hypersonic craft to approach the lateral skin maximum temperatures?

-Some hypersonic designs use a skipping stone flight model, where they accelerate in the upper atmosphere before pitching up into 100km+ altitudes, cooling down then diving back in again. If we use rockets for high thrust, would it be possible to drive a hypersonic aircraft to over its thermal limits between boost phases while staying by not spending enough time in the atmosphere to fully soak the skin?

I'm not at all sure there is a simple general answer to your two questions. To get better answers than I posted requires real finite-element analyses in three dimensions, with proper models for the heat transfer and the re-radiation, plus the internal conduction. I have no such capability here at home.

ReplyDeleteWhat I do know is the film coefficients and heat flow rates per unit area in a stagnation zone are roughly an order of magnitude higher than those of a fully lateral skin panel. The deeper you are in the atmosphere, the more staggeringly-huge these heat flow quantities are. That gets really hard to handle with liquid cooling internally, very quickly. The problem is boiling on contact, which is only prevented by extreme pressures.

I suspect the limiting factor for skip-glide cooling is the relative amount of time spent cooling "in vacuum", not how long it takes to heat up while deeper in the atmosphere. The heat-up happens very quickly. Cooling off is slower, because in practical terms, it still ain't vacuum. You still have some heating going on, just less of it as the air thins.

Hope that answers your questions. -- GW

Very interesting basic intro to hypersonics. You noted that there were only two mechanisms to cool a skin panel, radiation and backside cooling and that one would dump the heat from the skin back into the tank. The concepts that I've seen pressurized the fuel to limit boiling, ran it through the skin then recovered the enthalpy in the combustion chamber. Transpiration cooling by seeping coolent through the skin (or nose/leading edge) to be vaporized and "quenching" the boundary layer is another possibility. As you insinuate, constructing the exterior of an airplane similarly to the interior of a rocket engine is neither light, simple or cheap.

ReplyDeleteExcellent post, Vinyl Cutters Machines for retail thankful to all your team for sharing such best information.

ReplyDelete