Protecting aircraft against missiles and ground fire is an old need. Deceiving radar with chaff goes back to World War 2, although it wasn’t originally called “chaff” then. Flares came to be, with the advent of infrared (IR) guided missiles in the mid-1950’s. Chaff and flares are the original aircraft decoys.

The problem with these is that they depart quickly behind

the aircraft, so you have to carry and

dispense a lot of them. They have gone

too far away to do any good, in about 1 second

or so at modern jet aircraft combat speeds.

And when they run out, so does

your luck, if the threats are still at

hand.

The notion of the towed decoy was originally “towed chaff”

and “towed flares”. One replaces the

many small items with just one (or a very few) somewhat-larger items that would

stay in the right place close by the aircraft,

but for a much longer time (essentially throughout the engagement and

beyond).

There are two quite-different concepts regarding the towed

radar decoy application: the towed

hardbody decoy and the towed ribbon decoy.

There is only the towed hardbody concept currently available for the

towed IR decoy application.

Towed ribbons are a different “beast” entirely, and the available radar reflection technology

only supports their use for protecting extremely low-observables aircraft. Even that application has severe

limitations. Towed ribbons are not

covered here!

Some History

The original successful towed decoy concept demonstrator was

designed by my friend Byron Hinderer at what was then Tracor Aerospace, in Austin,

Texas. He did this before I ever

reached Tracor.

That decoy featured a dorsally-attached towline (termed “cg

tow”) on a very simple body with an aft-mounted ram air turbine (RAT). The RAT supplied the electric power to make

the radar receiver and transmitter aboard the decoy function. There was no power-down-the-towline. It successfully deceived all radars in flight

tests before the Navy, despite all sorts

of “experts” saying it could not possibly work.

I spent a little over 3 years at Tracor, working on (among several other things) towed

hardbody decoys, towed ribbon

decoys, and one IR signature generation

technique that might fly aboard one of the towed hardbody decoys. This included extensive ground tests, wind

tunnel tests, and flight tests. That testing led to some very successful

flight tests of various test articles,

and a prototype design for possible acquisition by the Navy, featuring power-down-the-towline. That last became ready a year or so after I

left Tracor.

The Navy initially bought a competing design from Raytheon

instead. There were severe “teething

troubles” with tow stability initially,

because Raytheon was using an incorrect design approach: nose tow like a gunnery target, producing both an uncontrollable rolling

motion, and a cone of no protection

directly behind the aircraft. That last

reflected a decoy located behind the aircraft at its same altitude.

What really works is quite unlike towed targets: one does a “cg (center-of-gravity) tow” from

a dorsal lug, which produces a decoy tow

point that is both behind, and somewhat

below, the aircraft. The cone of no protection (where decoy and

aircraft line up in the threat’s sight picture), is thus depressed below horizontal. Thus, there

can be effective protection from a threat in a tail chase from above. Because this works so well, towed radar decoys are now common among many

countries’ armed forces.

This same hardbody tow scheme could also be used as an “airframe”

for a towed IR decoy. If airbreathing

combustion is used to produce the IR signature,

then fuel does not necessarily have to be carried on board the

decoy. It might instead come down the

towline, as an option.

Engagement Scenarios

There are some things necessary to understand about the

characteristics of engagements between threats and aircraft. The air-to-air and surface-to-air scenarios

are different, but the critical features

are grossly the same. There’s basically

head-on attacks, attacks from the

side, and tail-chase attacks.

Because the missile threats all use one or another form of

what is called “3-D proportional navigation” for their guidance, the head-on and side attack geometries have

the tendency to convert toward the tail chase scenario. How close to a tail chase these scenarios

become varies, but it does point out the

need to have decoy protection in the tail chase scenario! This is illustrated with crude sketches in Figure 1.

Figure 1 – How the Various Engagement Geometries Tend To

Convert to Tail Chases

All these engagement aspects use the same basic 3-D

proportional navigation guidance. That

guidance has built into it something termed “gee bias” that more-or-less

eliminates the downward pull of gravity as a disturbing influence on the

missile. The usual implementation

overcompensates somewhat. That has two

effects: (1) the trajectory is bowed

upward, and (2) the thinner air at the

higher peak altitude increases the missile range, to whatever extent is possible. This is also illustrated in the figure.

The basic sight picture seen by the missile is then from

somewhere behind and slightly above the aircraft. One wants significant separation between

aircraft and decoy, as viewed in that

missile sight picture! If the decoy

lines up with the aircraft, then it can

afford no protection. That is the

definitional concept behind the term “cone of no protection”. What that really means is that you want that

cone of no protection to be depressed below horizontal, as shown in Figure 2. The exception is shoulder-fired IR, which is still coming up from below as it

turns into a tail chase. Straight tow is

better for that.

Figure 2 – Threat Sight Picture and Cones of No Protection

What is shown in the figure applies directly to non-imaging

threats (radar or reticle-based IR).

Radar sees reflected energy in this or that pixel, within its narrow field of view (FOV). The seeker itself steers in such a way as to

center that “bright” pixel in its sight picture. It is the off-angle position of the seeker

(plus the range information) that allows the guidance to lead the target, to a calculated intercept point in space. If more than one pixel has reflected

energy, the seeker tends to use the

“power centroid” of the multiple “bright” pixels as its aim point at the center

of its narrow FOV.

Reticle-based IR is somewhat similar (in not forming an

image), but lacks range

information, so the estimate of the

intercept point in space is somewhat cruder.

The seeker still steers itself toward centering the power centroid of

all the hot spots it sees, in the center

of its sight picture. Seeker deflection angle

generates the information for leading the target. Like radar,

it has a very narrow FOV. There’s

just no individual pixels (which there are,

once you start using imaging IR).

Here’s the key thing for any decoy: as the missile closes upon the aircraft, its sight picture of aircraft and decoy

becomes larger and larger.

Eventually, that whole picture

cannot fit within the FOV. If the decoy

is “brighter” than the aircraft, it will

be nearer the power centroid. The more

remote aircraft then drops out of the FOV first. After that,

the only target seen by the seeker is the decoy, and the missile steers toward it rather than

the aircraft, causing the miss. Its warhead may (or may not) fuse, since the decoy is so small compared to the

aircraft that the missile designers expected.

So, two things become

clear at this point: (1) you want a lower

tow for a widest-possible sight picture, while also depressing the cone of no

protection below the line-of-sight to the descending (or at least co-altitude)

threat, and (2) the decoy’s signature

(whether radar or IR) must be “brighter” than the aircraft.

The great benefit here is that 1 decoy serves for the 1

engagement. If it is shot away, you can dispense another one, but you need not dispense multiple dozens per

engagement, the way you do with chaff

and flares. You do not need to carry anywhere

near as many towed decoys, as you do

chaff and flares, which means the

typically-larger sizes of the towed decoys are no obstacle.

What I have said about threat guidance and engagement

characteristics so far is stuff that has been in the open literature for a very

long time. I cannot say much more about

that, without getting into ITAR and

classified information. That is the

realm of counter-counter measures: the

missile guidance recognizing decoy from aircraft, and then acting upon that information.

About Towed Hardbody Decoy Design Approaches

There’s low/straight tow,

side tow, and high tow, as possible places to locate a decoy (which

moves the cone of no protection). These

are illustrated in Figure

3. Only low/straight tow

requires no automatic flight controls for stability. Having to develop the flight controls to make

side or high tow stable and reliable, is

another big development effort beyond just getting the decoy to emit

signature.

Accordingly, the

simplest, easiest, and least expensive option is to do

low/straight tow. You do want as low a

tow as possible, for enhanced stability reasons,

as well as depressing the cone of no

protection well outside the engagement sight picture. That low/straight tow is the only topic I

cover here.

Figure 3 – Possible Tow Locations and the Associated

Considerations

How This Rough-Out Design Analysis Is Done

Start with the decoy itself:

first size its tail for high “arrow stability”, then second select a trimmed-out angle of

attack that gets high downforce, and then

finally size a tow lug height for net zero-moment about the cg at your desired trim

point. Such a decoy rough-out design

results in a tow force at an angle, which

also applies as a tension to the tow cable end, and as an angle boundary condition. See Figure 4.

The details of exactly how to do this are discussed below.

Figure 4 – The Design Analysis Sequence for Roughing-Out a

Towed Hardbody Decoy

Next, you do the

curved portion of the towline. The

entire tow line is modeled as a short straight length and a much-longer curved length. For simplicity in a design rough-out, I just use a circular curved shape. The angles at its two ends are the tow cable

angle at the decoy, and zero where it

joins the straight section.

Ignoring towline weight,

the curved towline lift force must exactly balance the total decoy

downforce, and the curved towline drag

adds to the total decoy drag for the line tension where it joins the straight

section. This is an inherently

iterative process: you simply change the

length of towline in the curved section, until the vertical forces balance to zero. Exactly how to compute those forces is

described below.

The drag of the short straight section adds to the tension

applied to its end, for the tension as

felt at the aircraft. That’s the largest

tension in the towline, steady state. The size and shape of the curved portion

determine its horizontal and vertical dimensions. These plus the length of the straight section

of towline determine just how far back,

and how far below the aircraft,

the decoy is actually located.

That in turn determines the depression angle of the line-of-sight from

aircraft to decoy, which is the axis of

the cone of no protection. Accordingly, it is wise to keep the length of the straight

section short.

Recommended Towed Body Geometry

We want the decoy to fly as low as we can, to depress the cone of no protection well

below horizontal. Square or rectangular

cross sections generate more body lift at a given angle of attack than round

cross sections. So, the square cross section is the best

recommendation. Those corners can be

slightly radiused without changing that effect.

See Figure 5.

Streamline bodies generate very destabilizing moments about

their putative centers of gravity (cg),

particularly those with boat-tails or pointed rear ends. The effect is reduced a little with a bluff

rear end, which reduces the sizes of

stabilizing tail fins needed.

Hence, the bluff rear end is recommended.

In the wind tunnel,

there was a rolling instability with a cross fin pattern that was simply

not seen with an X-fin pattern. This was

thought to be related to a sort of alternating vortex shedding off the two

horizontal fins in the cross pattern.

The X-fins are always slanted,

and thus the shed vortex positions seemed to be far more stable. Hence X-fins are recommended, even if the body has to be round in cross

section for any other reason.

Putting fin trailing edges flush to the bluff rear of the

body, positions those fins farthest from

the cg, which reduces their required size

a little. Thus aft-edge-flush fins are

recommended.

Any downlift fins added to the decoy should be positioned

with their center of pressure (cp) at the decoy cg. This minimizes downlift fin moment

contributions about that cg, while

maximizing their downlift effect, which added

downlift would be the only reason for having them.

The tow lug is located axially at the cg, and on the dorsal side of the body. The towline force component parallel to the

body axis, at the lug height, is the means to trim-out the body to fly at

the desired angle of attack. Otherwise, the stabilizing tail makes it want to fly at

zero angle of attack.

The figure shows a really odd-looking recommended nose shape

for the square cross section body that is recommended. There is a good reason for that:

In the pitch plane,

the rounded nose helps delay flow separation to a point well down the ventral

surface. This maximizes the forward ventral

surface suction component of the body downlift,

which downlift we greatly desire.

In the yaw plane, the edges are

sharp, leading to flow separation on the

lee side in yaw, right at the nose. This diminishes the yaw-inducing side forces

created by lee-side suction, thus

diminishing the response to any yaw disturbances while towing.

At best, this sort of

asymmetric nose shape is difficult to do with a round body cross section. A pointed cone or ogive nose shape is pretty

much all that can be done. Such will

have equal propensities for lift and yaw forces. This is something we saw in the wind

tunnel: at the higher speeds (higher

drag/weight ratios), the round bodies

were much less stable in yaw than the square bodies with the odd nose.

The opposite was true at very low speeds (low drag/weight

ratios). But it is the higher speed

range that is of interest for jet aircraft that might need towed decoys! If you must do a round body, put a sharp cone on it, and let the flow separation induced by the

cone-cylinder joint kill the yaw forces.

That also kills body downlift forces,

so you will need to add the downlift fins to get the tow position you

desire.

That being said, on

the square body section, you put any

downlift fins at the upper chine line,

positioned axially with their ¼-chord points at the axial cg

station. Those downlift fins see cleaner

air there (remember, we are flying with

the nose pitched down, not up) and are

thus maximally effective.

On the round body,

you put them straight out from the sides at the cg. They see cleaner air there, than anywhere else.

Figure 5 – Recommended Geometry for Towed Hardbodies

About the Aerodynamic (And Other) Forces

There are the forces from the body alone, the forces from the tail fins, and the forces from any downlift fins. All of these induce moments about the decoy

cg. At zero tow force, we want that moment sum about the cg to pitch

the nose up rather strongly. That is

how we obtain “arrow stability”. Adding

in the moment of the towline force about the cg, should create zero net moment at the desired

downward angle of attack. That is how we

“trim-out” the decoy to fly the way we want it to, on that towline.

Body lift and drag are located without any moment at all, at the axial position of the body center of

pressure (cp). As indicated in the

figure above, I recommend measuring

axial position from the nose of the decoy.

This cp position is denoted as body xcp,

which varies very strongly in location. At zero angle of attack, it is typically way out in front of the

nose, for just about any imaginable

streamline body shape. As angle of

attack increases (up or down), xcp moves

quickly to some position interior to the body.

Here, positive angle of attack is

down, and positive moment acts to

increase that angle of attack.

The amount of body lift varies nonlinearly with angle of

attack, differently for each possible streamline

body shape (airship hulls, bombs, etc.).

The xcp position also varies quite nonlinearly with angle of attack, differently for various shapes. The

best thing here is to select old plotted data for an appropriate shape, and curve-fit it; which is exactly what I did.

Tail fin lift and drag forces are located at the tail

cp, which for uncambered flat plate fin

shapes, is pretty much fixed at the

¼-chord point, with a zero moment value

about that point. That means the tail

xcp is at a definite location from rear edge of the body (and thus from its

nose).

The same is true for any downlift fins, you just locate them with their ¼-chord

points at the decoy cg.

That’s three sets of lift,

drag, and cp data: body,

tail, and downlift fins. Thus there are 6 aerodynamic forces, each contributing moments about the decoy cg.

The seventh is the towline force, and the eighth is the decoy weight. These forces and locations are shown in Figure 6. For these 6 aerodynamic forces, the relevant moment arm geometry in the wind

axis coordinates uses body axis moment arms and the appropriate sine and cosine

values of the angle of attack. The

towline force component parallel to the body axis, times the lug height, is that moment, using the sum of towline angle and decoy

angle of attack. The weight acts through

the cg by definition, and thus generates

no moment.

Figure 6 – Locations and Moment Arm Data for All 8 Forces

More

About the Body Forces

An old reference had a multitude of plotted curves of the

body forces for a variety of shapes.

Among them, the square section

lift curves had roughly twice as much lift as the round section lift curves. The variation is quite nonlinear, which is why I selected a cubic polynomial

for my curve fit.

The same reference had a relatively simple model for the

body induced drag, one peculiar to streamline

bodies alone. I used that. The body zero-lift drag is just a “typical

value” one can obtain from a variety of sources, including the ones I used.

At low angle of attack,

the body cp is way out in front of the nose, and moves aft as angle of attack

increases. Bodies with bluff rear ends

showed reductions in just how far ahead of the nose the xcp is, at zero angle of attack. The correlated variation for bluff-ended

bodies was also quite nonlinear, so I

used a cubic polynomial curve fit for that,

too. All of this is illustrated

in Figure 7, with the curve fits given in Figure 8, along with the reference whose data I used.

Figure 7 – What All the Body-Only Forces Look Like

More

About the Fin Forces

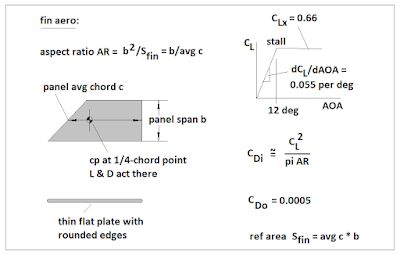

The fin forces are easier to deal with, since the centers of pressure are essentially

fixed in location at the 1/4-chord point.

Tail fin or downlift fin, the

fundamental single-panel geometry and data are shown in Figure 9. These are simple flat plate airfoils with

rounded edges. Post-stall behavior is

simply assumed, just to have “gross

ballpark” data.

For the tail fin group,

I assumed that the leading edges could be swept, if desired.

They do not have to be. The trailing

edges I assumed straight, unswept. For the downlift fins, I presumed a constant chord, unswept.

These are to be lifting wings,

after all. All these fin designs

will behave as low, to very low, aspect ratio surfaces.

Figure 8 – Curve-Fitted Plots of the Data for Square-Section

Bodies with Bluff Rear Ends

Figure 9 – Basic Fin Aerodynamic Data

Figure 10 – How I Handled the Twin-Tail Effect of the X-Fin

Configuration

The X-fin tail is a little different than in the usual

aircraft design practice. Because of the

angles, there is a cosine component to

apply, for a panel’s projected

area. But, there is also a sort of twin-tail effect that

increases the effective area beyond just the projected area (where one side

masks the other). This opens the door to

aerodynamic interference, so I did not

double it for the twin effect, as

indicated in Figure 10. You could use a round body, but you still put X-fins on it, per the wind tunnel experience.

Towline

Aerodynamics

The towline is an essentially-cylindrical shape, which in the curved section has some local

angle of attack in every segment. The aerodynamics

came from the old indicated reference shown in Figure 11 with the data, for a cylinder in crossflow. The reference area used for the aerodynamic

coefficients in that old reference calculates as Lseg*dia, which is a sort of “planform” area for the

segment.

These are very old results,

but they are still quite useful.

The drag coefficient is simple indeed at zero angle of attack, for the lift and drag coefficients equations

shown in the figure. It is just the

additive constant in the CD equation.

I modeled the curved portion of the towline as 10 finite segments, and simply added the lift, drag,

and geometry contributions of each segment to estimate the result of the

entire curved section of the towline.

The local angle of attack at the decoy end is identical to the decoy

towline angle determined from that analysis.

It is zero where the curved section joins the straight section. Being circular, the angle at each segment is quite easy to

determine, using a constant change from

segment to segment.

I did not include the weight of the towline in my

analysis. If I were to do so, I would need data on the weight per unit

length of the towline material, and

reduce each segment’s lift by the amount of its weight, before adding everything up. Most cords are rather light, so it seemed a rather inconsequential

effect, compared to the other

assumptions being made for this design analysis.

However, that might

not be as inconsequential, if electric

power or fuel were to be delivered down the towline. That’s a change I might add to the

spreadsheet in the future.

Figure 11 – Aerodynamic Model Used For The Towline

Running Example Cases

Two things needed to be addressed. First,

a guessed drag coefficient for the zero-lift body drag was not

sufficient. Second, online research revealed that operational towed

radar decoys that did not feature large drops behind the aircraft, but did feature shapes that would actually enhance

drag.

To address the drag coefficient, I used Hoerner “drag bible” again, this time going to his chapter 3, regarding the pressure drag, skin friction drag, and base drag of a variety of shapes. The pressure drag is primarily the drag of

the nose shape. His Figure 20 offered

useful data, as sketched in Figure 12.

For the square body decoy,

I used the average of the indicated drag coefficients for the

hemispherical nose (0.01 on body cross section), and the flat-ended bluff nose (0.80). That’s a 0.405 contribution for the

nose, and using the body cross section

area reference that I wished to use.

The same figure has a nose drag coefficient of 0.20 for a

rather bluff nose, but with a small

radius transition to the basic cylinder.

I used that for 90% of the nose drag,

and 10% of the flat-ended shape (0.80) to represent the effect of the

presumed igniter for an IR decoy. That

produced a nose contribution of 0.260 for the round-body decoy.

Hoerner offers a close approximation of the Schoenherr

turbulent skin friction model that is quite easy to use, and within about a percent of the Schoenherr

value. His equation 26 from chapter 2

for that is:

1/Cfwet^0.5 = 3.46 log10(ReL)

– 4.6, where Cfwet is based

on the wetted area, and L is the wetted

length

To convert Cfwet to a cross section area

basis, one simply uses the ratio of

areas:

CfB = Cfwet Swet/Ax, where CfB is the skin drag

coefficient referenced to body cross section Ax

For the 2.5 x 2.5 inch square body decoy, the wetted length is the full decoy length of

18 inches. Evaluated at 800 ft/sec at

5000 feet altitude on a US 1962 standard day,

the Reynolds number per foot is 2.826 million per foot. Cfwet

calculates as 0.00333, and it converts

to CfB = 0.0959.

For the 3-inch diameter round-body IR decoy, the situation is much more complicated, there being a more-or-less cylindrical body

about 10 or 11 inches long, followed by

a smaller diameter blast tube to the tail,

and a final full diameter short spoiler to hold the pyrotechnic flame in

place behind the decoy. The blast tube

is largely in a base-drag wake zone,

with flow attachment around the periphery of the spoiler, behind which there is another base drag wake

zone. See Figure 13.

I used 0.9 feet for the skin drag calculation of the forward

full-diameter portion, which produced a

Cfwet of 0.00365, which

converted to a CfB of 0.0535.

I used half the body cross section as the wake zone area behind the

forward body around the blast tube, plus

the entire body cross section for the wake zone behind the spoiler. I also

treated the reattachment on the spoiler as the same blunt-but-radiused nose

drag, on half the body cross section.

According to Hoerner,

the base drag is related to the skin friction drag ahead of the wake

separation, by his equation 34 in

chapter 3:

Added CDbase (on body cross section Ax) = 0.029/CfB^0.5

For the square body,

this figured as added CDbase = 0.050, and for the base drag behind the forward body

on the round decoy, 0.1253. I use half of that for the first wake on the

theory it is about half the area, and

all of it for the spoiler wake, it being

full size. The reattachment pressure

drag on the spoiler is half that of the nose drag, that being about half the cross section.

The zero-lift body-only drag buildups are:

Item square

body round

body

Nose (pressure) drag 0.405 0.260

Skin friction 0.0959 0.0535

Fwd base drag NA 0.0627

Reattachment pressure NA 0.100

Final base drag 0.050 0.1253

Total on Ax 0.551 0.602

The zero-lift drag of the fins get added to that of the body

in the spreadsheet. That sum is the

actual estimate of the zero-lift drag of the decoy.

To address towing with or without large drop, I took a clue from the tangent of the cable

angle being the ratio of decoy total downforce (which includes its weight) to net

decoy drag (which could be reduced by its thrust, if any). I ran 1 degree AOA cases square and

round, with and without downlift, to get a min tow lug height. I also ran 6 degree AOA cases, for something halfway to fin stall. These analyses were loaded into a spreadsheet

worksheet for easy iteration. I created

separate worksheets for the square body decoy,

and for the round body decoy. The

square body setup is given in Figure 14, and the

round body in Figure 15.

Figure 12 – Nose Drag Contributions Data From Hoerner

Figure 13 – Square Body and Round Body Example Cases

Figure 14 – Square Body Setup in the Worksheet

Figure 15 – Round Body Setup in the Worksheet

It proved possible to generate decoy tow point and towline

equilibrium characterizations versus AOA with the square and round body

decoys, each with and without any

downlift fins. These data were plotted

for comparison, as shown in Figure 16 for the

square body, and Figure 17 for the

round body.

Figure 16 – Square Body Results Vs AOA

Figure 17 – Round Body Results Vs AOA

One of the surprises was the occurrence of cable angle theta

plus AOA exceeding 90 degrees for both square bodies, and with the downlifter round body. You cannot actually reach that condition in

actual tow, it is simply an artifact of

the arbitrary calculation tables used in the two spreadsheet worksheets.

From these results, I

learned that tow lug exposed heights were acceptable at small values, for the 1 degree AOA data that I had

generated. Higher AOA will require

either an inappropriately-tall tow lug,

or else we must have added aerosurfaces to produce additional nose-down

pitch moment. Not knowing what might be

appropriate as a trim angle, I used 6

degree AOA data as “about halfway to fin stall”.

I did this design analysis at a speed and altitude “typical”

of a ground attack scenario, with a high-subsonic

weapons-release constraint. Such a

constraint is actually rather typical. The

hope is that there is sufficient excess stability embodied in the tail

sizing, that the effects of higher

speeds and higher altitudes are also covered adequately, for any reasonable engagement scenario.

The risk at higher speeds is that aerodynamic forces exceed

the weight so much that the decoy no longer passively “knows” where “down”

is. The risk at higher altitudes is

that, in the thin air, inertia coupling overcomes stability, a problem well-known in high-speed jet

fighters. That is, the control accelerations afforded by the tail

fin aerodynamic forces, in comparison to

the decoy inertia, are simply too small

to effect a timely recovery from any sort of disturbance.

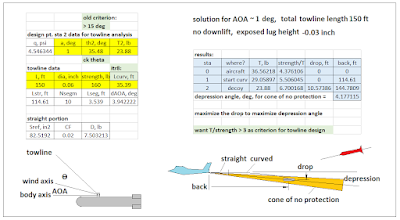

Ultimately, I did the

towline equilibrium calculations in the worksheets for the square body at 1 and

6 degrees AOA, with and without

downlift. And I did exactly the same

spread for the round body. The resulting

drops below the aircraft, distances

behind the aircraft, and depression

angles for the cone of no protection are all a function of total towline

length. So I ran multiple lengths for

these 8 cases, collated, and plotted the result data as depression

angle vs total towline length, for the 8

cases. Those plots are given in Figure 18. Three times a “typical aircraft length” would

be a towline 150 feet long.

Figure 18 – Tow Positions Vs Towline Length, All Cases

This is where the design solutions become very

judgmental. For the square body at 1

degree AOA, the exposed tow lug heights

are right-at about half an inch, which

is quite realistic. Adding downlift has

more effect with a shorter towline, but

that is not very advantageous toward aircraft protection. The “right” towline length seems to be about

3 aircraft lengths, or about 150

feet, based on what little open-source

information there is on the existing towed radar decoys. At that distance, adding downlift fins depresses the cone of

protection to 5 degrees from 4, which is

not much change at all.

Adding downlift has a lot more effect at 6 degrees AOA and

150 feet: about 21 degrees vs 12. Intuition suggests we only need about 9

degrees, so we don’t need the full 6

degrees of AOA. Interpolating

linearly, it would appear the

no-downlift square body needs about 4 degrees AOA, while the downlifter square body needs about

2 degrees AOA.

For the round body,

the picture is quite similar, but

the numbers are different, because there

is less body lift available. For no

downlift, the 6 degree AOA point

generates just about 9 degrees of depression,

no interpolation necessary. For

downlift, interpolation yields an

estimated 3 degree AOA.

The net result is 4 potential decoy designs, two square body, two round body, each with and without downlift, all at 150 feet total towline length, and all targeting 9 degrees of

depression. Plus, there are two more configurations (square and

round) that tow with little depression at 1 degree AOA, and which need no downlift. That spread is:

The towline equilibria and tow position data for these 6 configurations are given in Figures 19 – 24. Bear in mind that for all trimmed AOA values exceeding about 1 degree, the exposed tow lug heights become unreasonable, requiring the decoys to be fitted with additional aerosurfaces to add down-pitch moment. That affects both total downforce and net drag, and the results have to be recomputed in response to that design change. Adding downlift reduces that trim requirement.

Now, if the decoy represents totally passive protection, you need to depress the cone of no protection well below the line of sight to the approaching threat, which should be at least co-altitude, and maybe a little above. In other words, you need the most “low” of the “low/straight tow” that you can get. That means adding downlift for the min trim aerosurface requirement, whether square or round.

But, if the decoy is not passive, then you have information about from what direction the threat approaches. In that case, you turn across the approaching threat at high gee, to prevent it from achieving a tail chase. You must know whether it approaches from the left or right, so that you can turn across it: left if on the left, right if on the right. For those scenarios, little or no depression doesn’t matter. So no added downlift or trim surfaces are required, whether square or round.

Towline strength: some of these are still marginal at best, failing the old strength/load criterion.

Figure 19 – Results for Square Body, No Downlift,

AOA 4 Degrees, Target 9 Degrees

Depression

Figure 20 – Results for Square Body, Downlift,

AOA 2 Degrees, Target 9 Degrees

Depression

Figure 21 -- Square

Body, No Downlift, AOA 1 Degree,

Target “Low Depression”

Figure 22 – Round Body,

No Downlift, AOA 6 Degrees, Target 9 Degrees Depression

Figure 23 – Round Body,

Downlift, AOA 3 Degrees, Target 9 Degrees Depression

Figure 24 – Round Body,

No Downlift, AOA 1 Degree, Target “Low Depression”

Discussion of Results

The interpolated trimmed AOA results for the round-body

decoy designs with significant trimmed AOA hit the target depression pretty

close at the selected total towline length.

The square body designs with significant trimmed AOA are in the

ballpark, but fell a bit short of the

target depression, indicating that

linear interpolation is not very appropriate.

Further iterations would be required to hit the target depression

values, and to account for the drags of

the necessary trimmed-AOA aerosurfaces.

But for illustrative purposes,

these results are close enough,

just as they are.

If depression of the cone of no protection is

important, both body shapes

benefit from adding downlift surfaces,

as these reduce either the tall tow lug requirement to trim, or they reduce the size of any added

aerosurfaces necessary to trim out the AOA.

These decoys have lower tow points behind the airplane. That would be the downlift-equipped square

body at 2 degrees, or the

downlift-equipped round body at 3 degrees.

They do fail the towline strength criterion at least somewhere along the

towline, for the presumed towline

material, which was simple nylon mason’s

twine.

If significant depression of the cone of no protection

is not deemed necessary, then

very short tow lugs, no downlift

surfaces, and no added trim aerosurfaces

become feasible. These decoys have

smaller drops behind the airplane. However, these shapes are easier to package into a

dispenser. That would be the no-downlift

square body at 1 degree, and the

no-downlift round body at 1 degree. These

do achieve about 4 degrees depression,

on the same 150 foot towline.

Both meet the old towline strength criterion with the presumed nylon

mason’s twine material.

The square body options identified here meet all of the old

criteria for stable towed decoys. Such

designs would likely require few changes in experimental development testing to

perform adequately. The round body options

identified here fail the L/D and tail volume criteria, but not by very much. But it is a risk: some changes might become very necessary

during experimental development testing.

Results are summarized in Figure 25.

Figure 25 – Results Summary

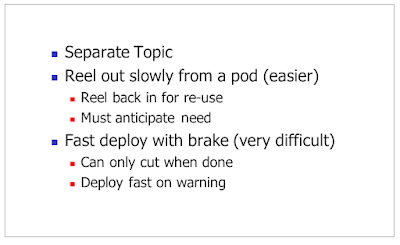

Deployment

Deployment is an entirely separate issue, as noted briefly in Figure 26. This topic was not covered

here, except in summary on that

figure. There are 2 options: slow reel and fast-braked. Slow reel could be reeled back in and

reused, but it takes long time to

deploy. Fast/braked is 1-shot

non-reusable, but can deploy very fast

at need. These are very difficult design

considerations indeed, involving large engineering

development efforts. None of those

issues were considered here.

Figure 26 – About Deployment, The Separate Issue

Final Remarks

A square body flight mechanics-only test article built to

these criteria, using these design

methods, was flight tested during 1987

at Flight Systems, at the Mojave Airport, on an F-4 “Phantom” aircraft. Flight test speeds were up to Mach 1.4, while flight test maneuvering gees were up to

6, in defensive-break maneuvers. The test pilot tried to break the tow

line, but could not. That towline was Kevlar, with very little elongation capability to

absorb line shock! That alone

demonstrates just how practical the towed hardbody decoy can be if designed

correctly! This is summarized in bullet

form in Figure 27.

Practical deployment design is an entirely separate

issue, which is its own topic. That is not covered here. The experimental test article was slowly reeled

out.

Towed ribbon decoys,

while covered by another worksheet in the same spreadsheet file, are also an entirely separate issue. Those are not covered here.

Figure 27 – Overall Conclusions

The US military is currently flying towed radar decoys. These include the AN/ALE-50 decoy for the

FA-18 and B-1B, the AN/ALE-55 fiber

optic towed decoy for the FA-18E/F (Super Hornet), and a version of the fiber optic decoy that is

being developed as the AN/ALE-70 for the F-35. Adding an IR option to the

AN/ALE-55 is also an option being considered.

The earliest one of these was the AN/ALE-50. It is the one that suffered “teething

problems”, until its manufacturer

Raytheon finally invented these same aeromechanics tow rules for

themselves. A different manufacturer (BAE

Systems) makes the AN/ALE-55 to fit the AN/ALE-50 dispenser, and is developing the AN/ALE-70, which requires a different dispenser not externally

exposed on the aircraft.

As for chaff and flares,

there is only one producer of chaff,

and two producers of flares, left

in the US. Esterline Defense

Technologies, also known as Armtec, makes both chaff and flares. It is now owned by Transdigm, which is known among some sources for

non-competitive price gouging. Kilgore

Flares company (a division of Chemring Countermeasures Company USA) also makes

flares. Chemring is in turn owned by a

company in the UK, thus being a

foreign-owned defense item source.

These are definitely business areas that could use some

competition.

Finally, I would

rather not share my towed decoy spreadsheet. However,

I might consult, using it.

No comments:

Post a Comment