I have corresponded with multiple friends recently over the merits of using an aerospike engine versus a conventional bell nozzle engine for flying from Earth’s surface into low Earth orbit. I conducted a design analysis using such nozzles, without pushing the state-of-the-art right to the edge, and I found even the sea level conventional bell to be much superior in vacuum.

What I uncovered during my design sizing analyses was: (1) not only was unconfined streamline

divergence a very serious problem for aerospike designs, as I have maintained for some years now, but also (2) there is a strong effect

favoring lower chamber pressures! Unless

one sharply reduces design chamber pressures,

the streamline divergence problem degenerates into complete infeasibility

at very low altitudes indeed. That

chamber pressure reduction has a big negative effect upon the thrust and

specific impulse that one can achieve,

including the effects of somewhat lower chamber c* velocity.

I did in fact confirm that my “roughly 60,000 foot

altitude” point, beyond which aerospike performance

falls while conventional bell performance does not, is

indeed correct! While still a

rather fuzzy boundary, my analyses do

show poor aerospike performance not far above that critical altitude.

Here Is Where I Started

I had done some nozzle evaluations and published an earlier

article on this topic (ref.

1). The free-expansion designs I

evaluated for that article were a twin-spike single-throat approach, not an annular or linear aerospike, but the behavior and physics are quite

similar. That is the genesis of Figs. 1 and 2.

Figure 1 – Basic Flow Physics of Conventional Bell Nozzles

Figure 2 – Basic Flow Physics of Aerospike Nozzles and Other

Free-Expansion Designs

The fundamental lessons as I initially understood them

are:

#2.

Free-expansion designs, including the

aerospikes, have ever-increasing

streamline divergence as ambient atmospheric pressure drops, while the expansion Mach number

increases. This leads to an

ever-increasing potential momentum term (and there is no pressure term) in

thrust. However, the streamline divergence angles quickly lead

to low cosine-components of the streamtube momentum vectors in the axial thrust

direction. At higher altitudes, this divergence inefficiency effect completely

overwhelms the larger momentum effect,

with the result that performance actually falls with altitude.

This Is What I Did

For the conventional bell cases, I used “typical” chamber c* = 5900 ft/sec for

LOX-RP-1 at 1000 psia Pc, from ref. 2, a modest modern max Pc = 3000 psia, a modest pressure turndown ratio (TDR) of

3, and a massflow bleed fraction of 5%

to drive the turbopumps. I did not

change the c* for the min Pc value, as

it is a small effect over that small a Pc range. The other variables were much more important.

I used the sea level chamber and throat design as the basic

common gas generator, by forcing the

design thrust levels for two higher-altitude designs (60,000 feet and 30,000

feet) to produce the same throat area At and flow rate values as the sea level

design. That produces a very fair

comparison, conceptually just

substituting one bell design for another onto the same chamber, throat,

and pump assembly, while also operating

at the same chamber pressures and propellant flow rates.

I used a simple empirical equation to estimate separation

pressure ratios from the bell’s average half angle. It works very well for conical nozzles, and runs slightly conservative with curved

bells:

Psep/Pc = (1.5 * Pe/Pc)0.8333

For the aerospike nozzle,

I started with that same Pc = 3000 psia gas generator, and sized low in the stratosphere, but the streamline divergence effects were

infeasibly extreme at 28 x 2 degrees.

The numbers simply made little sense.

I did notice a definite improvement at the min Pc over max Pc!

Therefore, I revised

the gas generator design to a max Pc = 300 psia, c* = 5700 ft/sec (reflecting the drastically-lowered

pressure range), TDR = 3 as before, and the same 5% bleed fraction. I sized for 100,000 lb thrust at 10,000

feet, using an aerospike that started at

56 degrees to axial, to zero the fan

angle at design. That gave me numbers

that actually made sense, and looked

very realistic.

I selected that design point thrust so that the sea level

thrust was comparable to the sea level bell design at 100,000 lb. That gave me flow rates somewhat higher than

the fixed-bell designs, primarily

because of the lower c* associated with the order-of-magnitude-lower range of

chamber pressures.

I used the Prandtl-Myer flow model of supersonic expansion

around a corner to estimate the flow divergence angles at the edge of the plume, based on the expected expansion Mach number

as determined by the Pc/Pa ratio. The

equations for Prandtl-Meyer expansion come from Ref. 3.

The orientation of the gas generator throat axis is the same

as the slope of the aerospike at its forward end, so that the attaching stream starts out

parallel to the adjacent surface. If it

were to impinge more directly, that

would induce a strong shock wave train on the aerospike surface, as it turns toward the axis direction, with corresponding large pressure

losses, disrupting the expansion.

I finally picked a 56 deg x 2 deg shape for the

aerospike, with the ring of thrusters 56

deg off axis at its start. The

Prandtl-Meyer angle gets that 56 deg subtracted off, because of thruster orientation, to determine the actual lateral divergence

fan angle of the plume relative to the thrust axis. Below design altitude, you get negative fan angle data, because the plume geometrically contracts due

to the changing shape of the aerospike. The

end of the aerospike is a small angle whose cosine is always near 1. Nozzle kinetic energy efficiency is just the

average of the cosines of the inner and outer angles.

At design, I used straight

axial and the aft aerospike angle to calculate the effective nozzle kinetic

energy efficiency. Both below and above design

altitudes where the plume edge is off axial,

I used the average of the fan angle cosine and the 2 deg aerospike

cosine, for my effective nozzle kinetic

energy efficiency. This efficiency is

just a cosine component correction to the plume momentum.

I needed a nonzero ambient pressure at 300 kft

altitude, instead of just using zero

representing vacuum. That zero works

fine for conventional bells, but is

inappropriate for estimating free-expansion designs. It drives the expanded area and Mach numbers

to infinity. Accordingly, I looked up a “standard atmosphere” model in ref. 4 that extended all

the way up to 300 kft geometric altitude.

It’s not an exact match to the standard atmosphere table from ref. 2 that I used, but it’s still “in-the-ballpark”, and gave me realistic numbers. The ref. 2 data only extended up to 200 kft.

Here Are The Results I Found

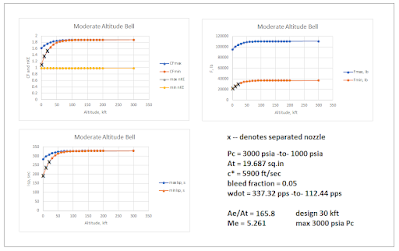

I selected relevant data for comparison of the conventional

bell designs, and arranged those as 3 plots

versus altitude on a single figure for each design. I created the same plots for the

aerospike, but needed a second figure to

display the variable expansion data and the streamline divergence data.

Figure

3 shows the baseline sea level conventional bell, Figure 4 a bell sized at 60,000 feet as if it were a “vacuum”

design, and Figure 5 a bell sized at 30,000 feet, representing a “compromise vacuum” design

that could actually be static-fired at sea level without separating. Figures 6 and 7 show the results for the aerospike design, with 6 showing the same content in the same format as

the conventional bells.

The sea level conventional bell in Figure 3 does not separate at full power or

min power, at any altitude. The exit pressure term on thrust shows significant

effect on thrust coefficient, thrust, and specific impulse up to around 60,000

feet, and almost no effect above

that. The change from sea level to

vacuum thrust and specific impulse (Isp) is quite modest, as would be expected from the very limited

expansion available for the fixed momentum term of thrust.

The same gas generator fitted with a “vacuum” bell (the

60,000 foot design in Figure

4) shows a potential for very significant thrust increase with

increasing altitude (due to the pressure term acting on a larger exit

area, along with a larger momentum

term). This obtains up to about 60,000

feet. There is very little effect from

there to vacuum. The problem is

that much of this potential is unrealizable for launch, due to flow separation in the bell near sea

level, even at max Pc, as noted in the figure.

The “compromise vacuum” design sized at 30,000 feet in Figure 5 shows behavior

intermediate between the other two extremes.

It has an intermediate momentum term and an intermediate exit area. The thrust increase with altitude due to the

pressure term is realizable at full power,

but not at min power due to flow separation, as shown in the figure.

The results for the aerospike design are given in Figures 6 and 7. More detail is required to understand the

expansion and flow divergence phenomena,

which is why Figure

7 is included. As a

reminder, the data in Figure 6 are the same

content and format as that presented for the bell nozzles.

The thrust coefficient,

thrust, and specific impulse data

increase to peak values in the stratosphere,

then decrease from there into vacuum! The peak is near 50-60,000 feet at full

Pc, and nearer 80-90,000 feet at min

Pc, so there is a strong pressure

effect favoring lower chamber pressures!

That is why I had to reduce the Pc range to 300-to-100 psia, from 3000-to-1000 psia for the conventional

bells.

The main difference between the aerospike and the

conventional bell designs is the effective nozzle kinetic energy efficiency

data that is shown in the same plots with thrust coefficient versus

altitude. The conventional bells all

have constant kinetic energy efficiency,

at a rather high value, all the

way out into vacuum. This reflects the

confined plume following bell angles,

right to the exit point (last point of contact). The exiting plumes suddenly spread wide, out in vacuum, but since that occurs downstream of the last

point of contact, it does not affect

the exit flow condition results.

The aerospike plume is unconfined laterally, and spreads very wide as altitude

increases. This shows up as an initially-high

effective nozzle kinetic energy efficiency,

that starts decreasing about 50-60,000 feet. It falls to drastically-low values

as altitude increases into space!

The details in Figure

7 show why: the fan-out angles

get very large, and simply overwhelm the

increasing expansion, quite

rapidly.

Figure 3 – Analysis Results For Sea Level Bell With Common

Gas Generator Design

Figure 4 – Analysis Results For High-Altitude Bell With

Common Gas Generator Design

Figure 5 – Analysis Results For Modest-Altitude Bell With

Common Gas Generator Design

Figure 6 – Analysis Results For Low-Altitude-Sized Aerospike

With Reduced-Pressure Gas Generator

Figure 7 – Analysis Results Details For Aerospike

The only thing that I found that I did not really expect

initially, was just how sensitive the

aerospike is to the aggravation of plume spreading effects at higher chamber

pressures! I could not get a feasible

design until I reduced the chamber pressures from thousands to only hundreds of

psia. That’s a factor-10 reduction

required! Otherwise, what I thought going into this analysis

turned out to be true. The list of

revised lessons follow (#3 Is the new one, no change to

#1 or #2):

#1. Conventional bells have inherently-limited

streamline divergence effects, with a

fixed (locked-in) momentum term in thrust;

plus an exit pressure term in thrust that differences expanded pressure

and ambient atmospheric pressure acting on the fixed exit area. If the ambient pressure is too high for the

expanded pressure, bell flow separates

and “kills” the momentum and pressure terms.

#2. Free-expansion designs, including the aerospikes, have ever-increasing streamline divergence as

ambient atmospheric pressure drops, while

the expansion Mach number increases.

This leads to an ever-increasing potential momentum term (and there is

no pressure term) in thrust.

However, the streamline

divergence angles quickly lead to low cosine-components of the streamtube

momentum vectors in the axial thrust direction.

At higher altitudes, the

divergence inefficiency effect completely overwhelms the larger momentum

effect, with the result that performance

falls with altitude.

#3. Aerospikes,

and presumably all the free-expansion designs, benefit strongly from reducing gas generator

chamber pressures by around an order of magnitude below modern rocket

practice. This acts to somewhat-limit

the adverse plume spread laterally, at

higher altitudes approaching vacuum. You

want that fan angle to be zero at your design point, which sets your forward spike and thruster

angle.

Final Remarks

Bear in mind that I already know how to optimize the designs

of conventional bell nozzles. I used to

do that for a living, long ago. I do not yet know how to optimize the design

of free-expansion nozzle configurations,

including specifically the aerospike nozzles examined here.

The aerospike configuration I came up with “worked”, but can hardly be said to be optimal! I had to compromise it severely by lowering

chamber pressure by a factor of 10 to match up plume boundary expansion effects

at the design point, with the

requirement that the plume boundary fan angle be zero. That also forced a very large initial spike

angle and mounting angle for the gas generator chambers adjacent to it. And it lowers chamber c*, and thus specific impulse.

Therefore, do not put

much credence in the lower specific impulse I got near design at low

altitudes, lower than with any of the

conventional bell nozzles. That is very

likely an artifact of my not knowing how to optimize the design of aerospike

engines.

Put your credence into the strongly-decreasing performance trends

at higher altitudes as you fly out into vacuum!

That is real, and even an

optimized design will show a similar trend!

It is inherent that the plume boundary will spread straight out to the

side as you fly an aerospike into vacuum,

and it is also inherent that this phenomenon will affect the thrust

level that can be achieved.

The plume inherently spreads laterally precisely

because of the physics embodied in Prandtl-Meyer expansion around a

corner. It does not matter if that

model needs modification to tailor it to this application or not, it will still show the same basic

plume-spreading trend.

Because this plume spreading takes place upstream of the

last point of stream contact with the engine hardware, it inevitably must affect the thrust! It is nothing more than velocity vector

component effects at off-axis angles. That’s

just the physics of compressible flow. No

one can argue otherwise. But it takes

place while the expansion is still occurring,

which in turn is what creates the thrust, which must be measured at that last point of

contact.

As a result, the effective

nozzle kinetic energy efficiency, the

achieved thrust for the flow rate, and the

delivered specific impulse, will inherently

show downward trends as one flies out into space. Whether I got the exact right numbers is

irrelevant. That downward trend, and the physics underlying it, are real!

Aerospike nozzles show excellent fluid mechanical

performance from the surface up to the stratosphere, probably better than with bell nozzles, if they can be correctly optimized. But,

the free-expansion nozzles will always show severe performance

degradation as you fly from the stratosphere out into vacuum! It is inherent, and it is unavoidable. It is a big effect!

The most important take-away: aerospike nozzles are simply NOT good vacuum

nozzles, despite what is often claimed. They inherently cannot be.

The better application for aerospikes is between the surface

and the stratosphere. That is where the

ambient atmospheric pressures are high enough to limit the plume lateral

expansion, which greatly improves the

effective nozzle kinetic energy efficiency.

I rather suspect that is true of any free-expansion design approach that

lets the plume boundary adjust prior to last point of contact with engine

structure.

The only thing I can think of to investigate further is to

add some nozzle expansion past the sonic throat of the gas generator

chambers, in an effort to limit the

Prandtl-Meyer fan expansion effect to lesser values, at least initially. This might also allow an increase in chamber

pressure, that being a lesser effect per

Figure 7 above. About the largest

expansion to add would be a sea level expansion. This does raise the risk of compression

shocks on the spike, as the Mach number

at impingement is higher.

Aside

As an aside, the

aerospike nozzle is in fairly wide use in some aircraft turbine engines that

lack afterburners. Those would be the

ones with a conical spike sticking out past the “turkey-feather” exit. These work from sea level to the lower stratosphere.

Stream pressures approaching the nozzle

are much lower than they are in typical modern rockets. All of that is favorable to aerospike

behavior.

When the turkey feathers form a convergent nozzle, and the internal stream pressures are high

enough to more-than-just-barely-choke that exit, this rig functions very well as an aerospike

nozzle facilitating a supersonic plume expansion to the last point of

contact: the tip of the exit spike. That increases engine overall thrust and

performance by increasing the nozzle thrust term in the airbreathing thrust

equation.

My Qualifications to Say These Things

My original college and graduate school education was in

high-speed compressible aerodynamics and thermodynamics/heat transfer, much of it oriented toward propulsion. I spent 20 years in aerospace defense work

doing compressible flow mechanics, including

specifically the operation of all kinds of nozzles for rockets, ramjets,

and other propulsion items, some

rather unconventional because of throat area modulation devices.

References

#1. G. W. Johnson,

“How Propulsion Nozzles Work”,

posted on “exrocketman” 12 November 2018.

#2. Pratt and Whitney “Aeronautical Vest-Pocket

Handbook”, 12th edition, 21st printing, December 1969; from “Theoretical Rocket Engine Propellant

Summary” page 92, for LOX-RP1 at 1000

psia; and from “U.S. Standard Atmosphere

– 1962” pages 4 – 9 for pressure ratio versus altitude.

#3. Ames Research Staff,

National Advisory Committee For Aeronautics (NACA) Report 1135

“Equations, Tables, and Charts For Compressible Flow”, 1953;

specifically “Prandtl-Meyer Expansion”, page 14.

#4. Chemical Rubber Company (CRC) “Handbook of Chemistry and

Physics”, 53rd edition

1972-1973, published by CRC Press; section F page F-171, metric or English abbreviated tables of the

US Extension to the ICAO Standard Atmosphere,

for the pressure ratio at 300 kft geometric altitude.

Related Articles

There are lists of articles on this site, organized by the topic areas they pertain

to. These are given in an article titled

“Lists of Some Articles By Topic Area”,

dated 21 October 2021. Related

topic areas might include “ramjet”,

“aerothermo”, and “rocket

performance”. I have added this article

to those lists.

The fastest way to access any given article on this site is

to jot down the dates and titles you want,

and use the fast navigation tool on the left side of this page. Click on the year, the month,

then the title if need be (if there was more than one posted that

month).

When looking at any given article, it is possible to see all the figures

enlarged, by clicking on any one of

them. You click on any of the small

images bottom of page, to see any one of

the figures enlarged. There is an X-out

feature to page top right, that takes

you right back to the article. You may

enlarge and X-out multiple times, as

desired.

There is also a list of keywords at the end of each

article. If you click on a keyword, you will see only those articles bearing that

same keyword. Top of the list is a “show

all posts” option.

Appendix

Here are images of the spreadsheet worksheets I used to

generate the plots given above, except

that I did not include the worksheet-generated plots in these images. The name of the spreadsheet file is

“nozzles.xls”. Figure 8 is the worksheet for the sea level

bell design. Figure 9 is the 60,000 foot bell as “vacuum

engine”, and Figure 10 the 30,000 foot bell as the

“compromise vacuum engine. Figure 11 is the

worksheet used for the aerospike. It has

to be laid out differently, as the

expansion is not geometrically fixed. Figure 12 shows exactly

how nozzle efficiencies were computed, and

what assumptions were made to do the analyses,

for both the bells and the aerospikes.

Figure 8 – Sea Level Bell Worksheet

Figure 10 – 30,000 Foot Bell Worksheet

Figure 11 – Aerospike Worksheet

Figure 12 -- Nozzle

Efficiency Calculations and Assumptions Made

Update 6 Feb 2023:

Doing exactly what was suggested above, I designed a revised aerospike nozzle that

uses some bell-confined supersonic expansion out of the gas generator, before doing the free expansion on the spike

from there to ambient. This actually did

reduce the expanded plume fan angles at high altitude, enough to raise the design altitude, and to re-raise the gas generator chamber

pressure from 300 psia back to 3000 psia.

These changes were beneficial enough to restore much of the compromised off-design

performance seen with the sonic-only gas generator design.

Results for thrust coefficient and nozzle efficiency, thrust,

and specific impulse are given in Figure 13,

which one should compare to the sonic-only gas generator design in Figure 6 above. Results for expanded Mach number, expanded area ratio, and the plume fan angles are given in Figure 14, which one should compare to the sonic-only

gas generator values in Figure

7 above. Formats are identical.

The best of the three fixed-bell designs was the one

designed for perfect expansion at a modest altitude, which gets a lot of improved vacuum

performance, while still being testable

at sea level in the open air, without

flow separation in the bell. Those

performance numbers are given in Figure 5 above.

In Figure

15, data are plotted for direct

comparison of the best fixed bell design,

and the best aerospike design,

for both at max Pc = 3000 psia.

In Figure 16, the same comparison plots are given with both

operating at min Pc = 1000 psia. Bear in

mind these are LOX/RP-1 designs that I arbitrarily roughed out. The “best bell” was sized to perfect

expansion at 30,000 feet so that it could be fired in the open air at sea

level, at full Pc. At min Pc,

it must be at or above almost 30,000 feet in order not to separate. It was sized with Fth = 106,230 lb. The best aerospike was the revised spike with

the supersonic-bell gas generators,

sized for an axial plume boundary at 60,000 feet, and a nominal thrust Fth = 100,000 lb.

There is still performance degradation with the revised

aerospike below fixed-bell levels, while

flying out into vacuum, but it is not

nearly as degraded as with the earlier sonic-only gas generator aerospike

design described above. This improvement

in performance was afforded by the limited supersonic expansion bell on the gas

generator, which limits how adversely-lateral

the plume angle can spread at lowest backpressures. The aerospike itself is a little less extreme

in its initial angle, as well.

That this revised aerospike is a near-optimal design

is confirmed by its specific impulse performance very slightly exceeding the

best fixed bell, from sea level to about

200,000 feet. For ascents, this aerospike might be competitive in terms

of performance, since the specific

impulse advantage in the stratosphere offsets the specific impulse deficit out

in vacuum, as long as it is not used for

too much impulse delivery out in vacuum.

For routine use out in vacuum,

the fixed bell is still better.

The original conclusion above that aerospikes are not

good vacuum nozzles really is confirmed in this update. However,

the vacuum shortfall definitely can be made more modest than was

originally indicated in the sonic-only gas generator version. One does that by fitting a sea level bell

upon the gas generator, allowing a reduction

in initial spike surface angle off of axial.

The mechanism of the fan angle reduction is the direction-confining

action of the modest bell, limiting the

further Prandtl-Meyer expansion angle from there to ambient, and which then also allows higher chamber

pressure.

The higher chamber pressure raises both c* and thrust

coefficient, which in turn acts to raise

specific impulse. The more-limited plume

fan-out angle in vacuum raises the effective nozzle kinetic energy

efficiency, which acts to raise thrust

and specific impulse. Of the two

effects, the fan angle dominates.

Figure 13 – Basic Results for Aerospike with Supersonic-Expanding

Gas Generator

Figure 14 – Detail Results for Aerospike with

Supersonic-Expanding Gas Generator

Figure 15 – Comparison of Best Bell and Best Aerospike at Max Pc

The basic message here is that by sizing the throat areas

correctly, the thrust shortfall evident

even in the stratosphere in Figures 15 and 16 can be eliminated! This will not really change the thrust

coefficient and specific impulse trends!

Those show the revised aerospike (with combined supersonic bell and

free-expansion spike) can equal or exceed the performance of the “best” fixed

bell up to the outer stratosphere (around 200,000 feet), but will inevitably fall short of

fixed-bell performance from the outer stratosphere on out into vacuum!

Those statements are made for a “modest vacuum bell”

design, sized to operate over-expanded

at sea level up to its design perfect expansion altitude of 30,000 feet. From there it operates under-expanded all the

way to vacuum, at the highest expanded-momentum

term available. That design selection is

limited by being able to test fire in the open air without flow separation at

sea level and full power. It cannot be

test-fired at sea level like that, at

min throttle.

The ”full vacuum bell” can equal aerospike performance in

the stratosphere, as indicated in Figure 17, but cannot be operated at sea level. However, note that out in vacuum, even a sea level bell outperforms the

aerospike! Aerospikes are quite simply not good vacuum

engines!

Figure 17 – 3-Way Comparison In Terms of Specific Impulse

Thank you for the analysis.

ReplyDeleteI guess these guys have minimal "aerospike" effects https://youtu.be/EY8nbSwjtEY

Watch for an update. I plan to examine what I suggested in the article as a better design.

DeleteThis is a very surprising conclusion! Why then are aerospike nozzles considered optimal for SSTOs, where average Isp is a critical measure?

ReplyDeleteThis stuff sells technology programs to government labs, that's why. Marketing hype. Aerospikes are really good from the surface to high in the stratosphere. They are lousier than a conventional sea level bell out in vacuum.

Delete