The rocket equation (as used in hand calculations) is shown in Figure 1. It inherently goes with a vehicle weight statement, also shown, in both mass and mass-fraction form. Whenever more than one weight statement applies, you may only do one rocket equation calculation for each weight statement. Velocity increments may be summed only if they occur within one weight statement!

You have a garbage-in, garbage-out (GIGO) problem with

rocket equation answers, if that weight

statement is not realistic! The

propellant mass fraction and vehicle mass ratio are utterly intrinsic to each

other, as the illustrated derivation

confirms. The calculated delta-vee (dV) capability

requirement must be sufficient to cover the required mission plus any gravity

and drag losses.

Figure 1 – Basic Rocket Equation Items

The basics for Earth launch eastward to low (about 300 km) circular

orbit at low inclination are shown in Figure 2 below. Launch is vertical, upward against gravity, but rapidly bends over in a non-lifting

thrusted gravity turn. Zeroing lift

minimizes the drag. The trajectory leaves

the sensible atmosphere at a still-modest supersonic speed, with only a slight upward angle “a” above the

local horizontal. If a two-stage-to-orbit

(TSTO) vehicle, this region is where

staging usually occurs.

For high-inclination orbits,

the dV should be increased by the eastward speed of the Earth’s rotation

at the launch site. For westward launch,

add two of those rotation speeds. Launch from other bodies is similar, except that the numbers are different, including those for the empirical fractions

from which gravity and drag losses are figured.

Ratio those Earth values, by the

ratios of the body’s surface gravity and “air” density to Earth standard values, for a first approximation.

In addition to determining dV capability from the rocket

equation, one must also size the thrust

of the engines in each stage. This is

very important, as the thrust required is

determined from the stage ignition mass,

allowing for the number of engines the stage must have. Engine mass affects the inert mass and inert

mass fraction in the weight statement!

Design iteration will be involved!

At launch, you want a

vehicle thrust/weight ratio at or above 1.5, in order not to burn so much propellant only just

above the launch pad, where speed is

still slow. Otherwise, you need to use a bigger gravity loss

fraction to figure the gravity loss you must cover with your dV

capability. Effectively, you want the net vertical acceleration above

gravity to be half a standard gee or more, to use your propellant more efficiently. This is empirical, but it has long-proven to be necessary.

Similarly, if your

vehicle is two stages, there is a

similar empirical acceleration requirement at stage 2 ignition, in order to use your propellant more

efficiently. You want half a standard

gee net above the vector component of gravity along your flight path. The simple equation is in the figure.

Figure 2 – Launch Mission Basic Items

The first figure showed how to obtain the effective exhaust

velocity Vex from the published rocket engine specific impulse Isp. Vex is what Isp would be, if it were defined in terms of

dimensionally-consistent units. It is

not: lbs of thrust divided by

lbm/sec of flow rate, and dividing-out

lb with lbm to obtain seconds, is not

dimensionally consistent! Nor is kg-f (or

metric tons-force) of thrust divided by kg/sec (or metric tons/sec) of flow

rate, and dividing-out kg-f with kg (or

metric ton-force with metric ton) to

obtain seconds! However, that tradition is too old and

well-established to change. Just deal

with it! In typical metric units, gc = 9.80667 m/s2. In US customary, it is gc = 32.174 ft/sec2.

Clearly one needs a good figure for Isp, in order to have a realistic value of Vex. The published textbook data versus propellant

combinations is crudely in the ballpark,

but not good enough for actual design! It is figured for fixed chamber pressures

that may not be the ones you want. It is

figured for fixed expansion ratios that are unlikely to be the ones you want. It is figured for 100% nozzle kinetic energy

efficiency which no real nozzle has. It

is figured for zero turbopump drive bleed gas dumped overboard, which might not be the turbopump drive cycle

in your engine. All these things affect

Isp quite strongly, except nozzle

efficiency, which is usually near 98-99%.

The best Isp estimate comes from doing the engine ballistics

yourself, per Figure 3 below. The first thing to go look up

is the data representing your desired propellant combination. That would be the chamber characteristic

velocity c*, the mixture ratio r, and the combusted gas ratio of specific heats

γ. You need a delivered c*, not a thermochemical theoretical value. The c* value and its efficiency are weak

power functions of chamber pressure, at

around 95-98% efficiency.

The second thing to quantify is the nozzle

entrance chamber pressure Pc (and pressure turndown ratio P-TDR) and dumped

bleed fraction BF corresponding to the engine and its turbopump drive cycle

that you desire to model. You need to

define max, min, and an intermediate Pc, values.

The third thing is to quantify the

characteristics of your nozzle: the throat discharge efficiency coefficient CD, the two bell half-angles a1 and a2 (if a

conical nozzle, then they are the

same, at the cone half-angle), the geometric throat area At and the geometric

exit area Ae, plus the ambient

atmospheric pressure Pa. CD

is effective throat flow area divided by geometric throat area. It is usually in the vicinity of 98-99.5%, if the profile into, through,

and beyond the throat is smooth and well-radiused. The profile radius to throat diameter ratio

should be about 1, with a short throat

flat.

The fourth thing is to do the compressible

flow nozzle analysis, which is usually

best done iteratively in a spreadsheet, the details of which are not

given here. That analysis determines the average

expansion bell half angle “a”, the

nozzle kinetic energy efficiency ηKE, and the expanded Mach number Me and pressure

ratio Pe/Pc, using the expansion area

ratio Ae/At and the specific heat ratio γ.

From those the thrust coefficient CF is determined as shown. This

includes the vacuum thrust coefficient CFvac, and the backpressure correction term, which is zero, if out in vacuum.

The fifth (and final) thing is the estimation overall

engine performance values. Thrust down

in the atmosphere is computed from chamber pressure Pc, nozzle throat area At, and the thrust coefficient CF as

shown. The relevant specific

impulse for the rocket equation must use the propellant flow rate

actually drawn from the tanks wtot. Isp can be computed either way, as shown:

from thrust and flow rate, or

from CF and c* plus a couple of other factors. For an estimate of vacuum performance, use instead CFvac as your thrust

coefficient, and figure the values with

it. In that way, sea level and vacuum performance are very

easily and quickly estimated.

Not shown in the figure is something easy to generate, if the nozzle expansion is analyzed with a

spreadsheet. By means of a standard table

of atmospheric pressure values, versus a

list of altitudes from sea level to space,

it is quite easy to obtain thrust and Isp performance versus

altitude, and even to plot it. Calculate the constant vacuum thrust and

subtract from it the varying backpressure correction term. Doing that kind of thing reliably may require

estimating the values of backpressure that cause bell flow separation! The entirely-empirical equation for that is

not in a figure, instead it is given

here:

Psep/Pc = (1.5*Pe/Pc)0.8333

That being said, optimizing a nozzle is a

separate topic in and of itself, not

shown here. Suffice it to say

that a sea level-optimized nozzle would have Pe = Pa at the nozzle design value

of Pc. There is no such thing as a “vacuum-optimized”

nozzle! There is only the max exit area

ratio that results in engines that will geometrically fit within the base volume

of the stage, allowing for

gimballing.

How to optimize Pc and nozzle expansion for best ascent-averaged Isp is

a separate topic, not illustrated here. By sacrificing some sea level thrust and

Isp, vacuum thrust and Isp can be

improved over the vacuum performance of a standard sea level design. In effect,

the nozzle is “designed” at a higher altitude than sea level, and operates over-expanded at sea level, but very definitely not so over-expanded that

it risks separation at sea level, for useful chamber pressures.

The next separate topic not shown is exactly how to estimate ascent-averaged

Isp. Some simply

arithmetically-average sea level and vacuum Isp, but that is really a lower bound, not a proper and representative average. The “right” value would have to come from a

trajectory simulation, which defeats

the purpose of simple “by-hand” estimates!

The procedure recommended here would be to compute performance versus

altitude in a table in the spreadsheet-based nozzle analysis, and simply average all the values in

the table. It’s not

“right”, but it really is fairly close.

Figure 3 – The Ballistics of Liquid Rocket Engine

Performance

The vehicle inert mass buildup is absolutely crucial to

getting a reliable weight statement,

so that the rocket equation result is also reliable. This is complicated by the fact that mass

ratio is related to mass fractions as well as masses, but you have to start somewhere. It is further complicated by the fact that

you need the propellant mass in order to estimate the inert mass of the tanks

that hold it, and you need the ignition

mass to estimate the stage thrust, from

which you estimate the inert mass of the engines that produce it. There are also interstage rings and skirts to

estimate, as well as fixed equipment

items like guidance and control hardware,

and the electrical power source that runs it. All

of this is indicated in Figure 4.

Figure 4 – Dealing With Vehicle Inert Mass Items

Usually, the analyst

is interested in delivering a certain payload mass to orbit. Guess a payload mass fraction, and a stage inert mass fraction, and compute the propellant fraction from them

as propellant fraction

= 1 – payload fraction – inert fraction. Convert the propellant fraction to mass ratio

MR as shown in the first figure above.

See if the resulting dV covers the mission

requirements; if not, adjust payload fraction (and perhaps also the

Isp) until it does. Then use

those fractions and that payload to run the actual masses in the weight

statement, and use those to estimate the

inert mass buildup, and the resulting

inert fraction. Keep iterating

until the inert fraction as used by the rocket equation agrees with the inert

fraction from directly estimating inert masses of tanks, engines,

equipment, and the various

interstages and skirts. The

payload mass and its mass fraction give you the ignition mass. That and the fractions for propellant and

inerts give you those masses. Always do

the check sums to see if you did the arithmetic right.

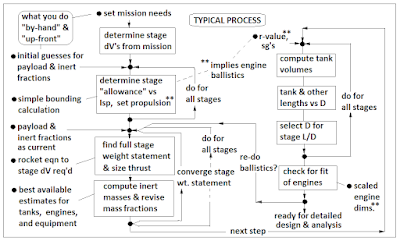

This weight statement convergence process is very

iterative, and the best way to do it is

with a spreadsheet. See Figure 5. You have to do two such convergence analyses

for a two-stage vehicle. The payload

mass for the first stage is the fully loaded second stage. Do the second stage first, because of that linkage, then do the first stage using that second

stage ignition mass result.

Figure 5 – Recommended Procedure to Converge the Stage Weight

Statement

There is one final aspect for sizing-out a design

concept, short of actual detailed

design. You need to estimate tank

volumes and other geometry, to estimate

a length and a diameter for the vehicle at launch. As indicated in the second figure above, this overall geometry impacts the drag loss

very significantly. This is

therefore a very important step, and a point

of further design iteration. Again, this might best be done in a spreadsheet.

Per Figure 6 below,

split your propellant mass Wp into oxidizer and fuel masses, then use their specific gravities to turn

those masses into volumes. As a

function of diameter, estimate the

tank overall lengths for the stage, and

add them. Select a number of engines to

produce the thrust. Add in a good guess

for the summed length of (1) an interstage with the G&C and power, (2) a between-tanks interstage, and (3) another good guess for the engine

overall length. That last can be modeled as

twice the expansion bell length, to

cover both the turbopump drive cycle equipment and chamber, and the gimballing engine mount. Then compute stage L/D, and select from the list the diameter that

gives the right stage L/D.

For a single-stage-to-orbit (SSTO) vehicle, this would be about stage L/D ~ 6 without the

payload, producing a still-larger, and definitely lower-drag, L/D with the payload atop the stage.

For a TSTO, do the

same procedure on the first stage, using

a desired L/D in the 3-4 range. Then make

the second stage the same diameter and find its L/D. Sum the L/D’s for the two stages

together: you will again want about 6 for

the two stages together, without the

payload.

Figure 6 – Running the Geometry from the Weight Statement

You will have already needed to set a number of engines for

each stage, and to re-scale their dimensions

from the ballistics analysis thrust level to the as-sized thrust level. Dimensions scale proportional to the square root of

thrust.

Once the vehicle is sized,

check to make sure your engines will actually fit the bases of the

stages. You may need to revise vacuum

engine expansion ratio to change the exit diameter and bell length. Or perhaps change the number of engines (and

rescale them). Or both.

The result of doing all of this correctly is the roughed-out

sizing of a credible launch vehicle concept,

and good ballpark estimates of its performance and payload

capability. Such is now ready for you to

invest in actual detailed design and analysis,

especially if it is the best concept you have evaluated, among several competing concepts.

Doing this “up-front” stuff by-hand (assisted by

spreadsheets) is the way to reduce the cost of evaluating multiple concepts

inexpensively and quickly enough, to

permit raising the odds of success, by

using true brainstorming to generate multiple concepts. See Figure 7, which applies to all sorts of engineering

development efforts, not just sizing

launch vehicles.

Figure 7 – General Development Process That Includes

Brainstorming Cost-Effectively

Where to Obtain the Spreadsheet Tools

There are three general-application spreadsheet tools that

support doing this kind of analysis. There

is a fourth spreadsheet tool that is not general, but is useful for making oversimplified

bounding calculations, for Earth launch

SSTO and TSTO concepts. See Figure 8.

Figure 8 – Available Spreadsheet Tools and Supporting

Materials

The first general tool is a 2-body elliptic

orbits calculator that can be used to determine the theoretical velocity

requirements of space missions. Its

results must be tempered with some empirical estimates for losses, in order to determine the mass

ratio-effective delta-vee (dV) numbers.

Those loss estimates and that orbit analysis are not covered here.

Another general tool is a rocket engine

performance calculator in which the propellant combination is modeled with a

specific heat ratio γ, a chamber c*

velocity as a function of chamber pressure,

and an oxidizer/fuel mass flow ratio “r” that is also a function of

chamber pressure. The nozzle is modeled

with half-angles for its kinetic energy efficiency, and a throat area massflow discharge

coefficient (or area efficiency). The

nozzle expansion conditions and thrust coefficient are sized from an appropriate

chamber pressure level, and either

a design expanded pressure, or a

design expansion area ratio. The engine

cycle is modeled by the throttleable range of chamber pressures, and the dumped-bleed fraction of turbopump

drive gases.

The third general tool is a reentry dynamics

and stagnation convective heating calculator that is based on the simple model

used by H. Julian Allen for warhead entry back in the 1950’s. To it,

I have added a stagnation plasma radiation heating estimate. The atmosphere is modeled by a “scale height”

type of simple exponential model for density versus altitude, and an altitude at which “entry interface”

begins at orbital-class speeds. The

entry conditions are speed and path angle at entry interface. The entering object is modeled by its

hypersonic ballistic coefficient and (only for heating) the effective value of

its “nose tip” radius.

The oversimplified rocket vehicle sizing tool for

bounding calculations presumes that there is only one weight statement

involved, so that all the dV values may

be summed into a simple calculation for each stage. It does include the sizing of stage thrust

values, which impacts inert masses, and it does estimate tankage volumes, which also impact inert masses. This is done in a way that allows the user to

force clean, low-drag shapes, of adequate but not excessive slenderness

ratio. But it is also only a bounding

calculation, a good start-point for

more investigative design. The numbers

are indicative, but not really

trustworthy.

These tools are available as free downloads by way of the

Mars Society’s “New Mars” forums, as

indicated in Figure 9 below. Those

same postings also offer a whole series of course materials as free

downloads, that teach the user how to do

these various things, in greater

detail.

For the four spreadsheet tools discussed here, the links from the New Mars forums postings

are reproduced here:

Item name (link below)

2-body orbits spreadsheet orbit basics.xlsx https://www.dropbox.com/scl/fi/cxtpsx2ne7ltg77syavxt/orbit-basics-spreadsheet.xlsx?rlkey=w6g4p5et7yacnxrwls5inmkmv&dl=0

Rocket performance spreadsheet liquid rockets.xlsx

Rocket user manual document user man.pdf

Results reporting image engine sizing

report.png

Entry spreadsheet entry

estimates.xlsx

Entry user manual document user manual revised entry.pdf

Oversimplified rocket vehicle

sizing tool launch sizing.xlsx

User Manual part 1 of 3 user

manual launch sizing.pdf

User manual part 2 of 3 addendum

to user manual.pdf

User manual part 3 of 3 addendum2.pdf

Figure 9 – Where to Find Links to the Tools on the New Mars

Forums

How to Do the Initial Bounding Analysis for SSTO

One can get a crude approximation to get started, by doing a rather simple bounding calculation

with the rocket equation. The vehicle

sizing / bounding calculation spreadsheet tool can be used for this. The numbers are not trustworthy for

design, but they are indicative. Figure 10 shows the sort of inputs

that you need. LOX is liquid

oxygen. LH2 is liquid hydrogen. LCH4 is liquid methane. RP1 is rocket-grade kerosene.

Figure 10 – Data Sources for the SSTO Bounding Analysis

The rocket equation-in-reverse is used to determine the

propellant mass fraction, and from that

the “allowance” that you have for the sum of inerts and payload. Results are given in Figure 11.

Where the allowance curve is above the inerts-only

band, there is the possibility of

carrying payload. The bands for

inerts-only fractions in the plot at lower right are based on miscellaneous

modern stages for the expendables,

Falcon cores for the reusable first stages that enter at low speeds, and good educated guesses for fully reusable

items capable of orbital entry and some sort of landing.

Note that reusable first stage cores do not apply for SSTO

bounding purposes, as they are not

orbital entry-capable. They tend to hit

atmosphere at only about Mach 3, whereas

full orbital entry hits atmosphere at about Mach 25. The entry heating is vastly different!

The figure shows a spreadsheet image and 3 plots made from

it, annotated appropriately. Required mass ratio MR is shown versus

propulsion specific impulse Isp, which

is what most people look at, but is the

least informative. There is a plot of

both propellant mass fraction Wp/Wig and the “allowance” for the sum of inert

and payload fractions, but the scale is

inconvenient. The most informative plot

is only “allowance” versus Isp in the lower right, where bands of inert fraction Winert/Wig at

zero payload fraction Wpay/Wig can be spotted upon it, as well as bands of possible Isp versus

propellant combination. That is the most

useful for bounding calculation purposes.

Figure 11 – Results for Initial SSTO Bounding Calculation

What we actually see from the lower-right plot is that an

expendable SSTO can be propelled with any of the 3 propellant combinations

investigated. However the payload

fraction potential with LOX-RP1 is essentially nil, and with LOX-LCH4 it is very small (on the

order of only 1-2%). With LOX-LH2, expendable SSTO payload fraction potential is

significant (on the order of 4-7%).

It is very unlikely that the inert fraction of a reusable

SSTO powered by LOX-LH2 could ever be as low as 10%, but if it were, the payload potential might be on the order

of 1%, and that only with the highest-possible

engine performance.

It is far more likely that the inert fraction of a reusable

LOX-LH2 SSTO would fall in the range of 15-20% (or even more, depending upon how the landing is to be done, and whether it is a lifting body or has wings), which falls above the required allowance

curve! That very clearly precludes

the possibility of successful reusable SSTO design even with LOX-LH2 propulsion,

and even at zero payload fraction! Such

a design would need something significantly better than chemical rocket

propulsion as we know it today (required Isp in the 500-1000 sec range, or more).

Details: More About Doing Engine Ballistics

The liquid rockets.xlsx spreadsheet does liquid rocket

engine chamber ballistics (from propellant and cycle information) and

expansion nozzle compressible flow analysis (to include both sizing the

expansion, and calculating resulting

performance). Results from both topics

combine to produce the engine specific impulse values.

The propellant information includes models for c* and r

versus chamber pressure Pc, where that

is at the entrance to the nozzle,

downstream all of the engine cycle features and components. The pressure feeding-in to those features from

the pumps can be, and most often

is, substantially higher! Chamber ballistics is primarily determining

the throat area and nozzle propellant flow rate to meet a thrust requirement at

a certain Pc. The throat area discharge

coefficient CD is a real-world efficiency factor that is part of the

nozzle flow determination.

There is no need to model all the details of the engine

cycle that drives the turbopumps. This

usually involves hot gas taps,

preburners, and/or stages of

combustion at off-design mixture ratios.

All we need to know to estimate engine specific impulse Isp is

the fraction of massflow dumped overboard (BF) relative to the massflow drawn

from tankage. The sum of nozzle massflow

and dumped massflow equals the massflow drawn from tankage.

The nozzle is a converging-diverging channel for which the

diverging portion usually has one conical half-angle near the throat, and another smaller one at the exit. These two angles are used to estimate rather

closely the kinetic energy efficiency ηKE of the nozzle, a real world efficiency factor that helps

determine thrust coefficient accurately.

It represents the exit area average of the cosine component factors of all

the exiting streamline velocity vectors.

The effects of fluid friction are essentially zero compared to this

streamline divergence effect, which is exactly

why propulsion nozzle expansions can be modeled quite well with isentropic

compressible flow models.

The thrust coefficient provides a very convenient way to directly

relate thrust to chamber pressure, and

to hardware size (in the form of geometric throat area). It is composed of a vacuum thrust

coefficient, less a backpressure

correction term. The vacuum

thrust coefficient depends only upon the expansion geometry Ae/At and kinetic

energy efficiency ηKE. The

backpressure correction term depends upon the expansion geometry Ae/At, the chamber pressure Pc, and the ambient atmospheric pressure Pa. It is zero,

out in vacuum where Pa = 0 by definition.

Vehicle performance depends upon the thrust, and vehicle mass depends upon the propellant

drawn from the tankage. So for the

rocket equation model to apply, the engine

specific impulse must be based upon the massflow drawn from tankage, not just the nozzle massflow, which is smaller if BF is not zero. In such cases,

specific impulse is higher if computed with the nozzle-only

massflow, something often reported for

marketing-hype purposes! But using it

leads to incorrect answers in rocket equation vehicle performance estimates!

This picture is represented conceptually in Figure 12.

Figure 12 – How Liquid Engine Ballistic and Performance

Estimates Are Done

The solid rocket has quite different engine

ballistics from the liquid, so the

liquid engines.xlsx spreadsheet is entirely inappropriate for calculating their

estimates! Only the nozzle sizing

and performance calculations are identical,

which deceives many newcomers to this field. To analyze vehicles powered by solid

rockets, you need a reliable specific

impulse value, but how you get it is

entirely different from the way you get it for a liquid.

The solid has exactly the same nozzle massflow equation for

a given chamber pressure, which in

steady operation must exactly match the massflow coming off the burning surface

of the propellant grain (a term for the propellant charge). That burning surface can vary during the

burn, sometimes drastically. But the main quandary is that the propellant

burn rate is a power function of chamber pressure (for no erosive

burning)! A lesser complicating factor

is that the chamber c* velocity used in the nozzle massflow equation is also a

weak power function of chamber pressure.

For no erosive burning,

there is a balance of the nozzle and propellant grain massflows, with chamber pressure appearing in 3

places, distributed on both sides of the

steady balance equation. (This gets to

be transcendental with erosive burning,

making the direct solution for Pc impossible.)

Solving this balance for the chamber pressure reveals an

exponential sensitivity of equilibrium pressure to variations in any of the

factors in the equation. The higher the

burn rate exponent, the more sensitive

this balance is. Also, the motor blows up anytime the sum of burn

rate exponent and c* exponent equals or exceeds 1! See Figure 13.

Figure 13 – The Ballistic Balance in a Solid Rocket Motor

The basic message here is that you need a solid rocket

analysis code or spreadsheet to properly determine the sizing and performance

of a solid motor. An introduction to

what that really looks like is given in the “exrocketman” article “Solid Rocket

Analysis”, posted 16 February 2020. (That site is http://exrocketman.blogspot.com.) One can quickly navigate to the article

using the archive tool left side of page.

Click on the year, then the

month, then the title if need be. In this case,

there is no need to click on the title,

the article was the last thing posted that month, top-of-list.

This is a very large topic and article! Note that with solids, there is no bleed fraction BF and there is no

pressure turndown ratio P-TDR;

plus, the oxidizer/fuel mixture

ratio r is meaningless.

The hybrid rocket has quite different engine

ballistics from both the liquid and the solid,

so the liquid engines.xlsx spreadsheet is entirely inappropriate for

calculating their estimates! The

regression rate for an unoxidized fuel looks like the erosive burn rate

correlations for solid propellants. For

an under-oxidized fuel, it has both the

exponential pressure dependence term, and the erosive burning term, for a two-term regression correlation in 2

different variables.

Only the nozzle sizing and performance calculations are

identical, which again deceives many

newcomers to this field. To analyze

vehicles powered by hybrid rockets, you

need a reliable specific impulse value,

but how you get it is entirely different, and is not discussed here at all. Apparently,

only numerical simulations really work at all.

Details: Analyzing and Optimizing Conventional Fixed-Bell Nozzles

Nozzle sizing and performance for rocket engines is best

done with the compressible flow model,

at no gain in entropy (“isentropic flow”), albeit with empirical corrections for the

effective throat area in terms of massflow (discharge coefficient CD), and with empirical corrections for streamline

divergence effects at the exit area (nozzle kinetic energy efficiency ηKE). That is how one obtains a reliable figure for

the actually-achieved estimated value of thrust.

For sizing, there is

(1) the expansion area ratio Ae/At and its effects upon expanded Mach number Me

and pressure ratio (Pe/Pc or Pc/Pe), and

(2) the effects of hardware size (embodied as throat geometric area At) upon

design thrust F at some design chamber pressure Pc.

Figure 14 – Calculating Sizing and Performance of Nozzles

It is possible to determine the expanded Mach number Me from

the design value of the expanded pressure ratio, in a closed-form solution, using Pc/Pe = [1 + (γ – 1) Me2/2]γ/(γ

– 1). The easiest way to do this is

to convert the pressure ratio to a temperature ratio Tc/Te = (Pc/Pe)(γ –

1)/γ = [1 + (γ – 1) Me2/2].

Then solve the temperature ratio equation for the Mach number: Me =

[2*(Tc/Te – 1)/(γ – 1)]0.5 . The

expansion area ratio can then be calculated with that Mach number from the

compressible streamtube area ratio equation:

Ae/At = (1/Me)[2*(Tc/Te)/(γ + 1)]0.5(γ + 1)/(γ – 1). These

are the standard isentropic relations.

It is not possible to determine the expanded Mach

number directly from the area ratio as a closed form solution. The compressible streamtube area ratio

equation is transcendental in Mach number,

so that solution is inherently iterative. That is where software or a spreadsheet can

be used with great labor savings. Once

that Mach number is known, it is used in

the pressure ratio equation to determine the exit expanded pressure.

“Sea level-optimized” designs are generally perfectly

expanded (Pe = Pa) at sea level, for the

design value of the chamber pressure.

That might (or might not) be the max value the engine is capable

of, but it will be close, something like 80+% of max. These designs then have the lowest area expansion

ratios Ae/At, and the least vacuum

thrust (where the exhaust is inherently underexpanded, to that least expansion ratio).

There is no such thing as a “vacuum-optimized”

nozzle design! Such a thing

would have an infinite expansion ratio (and dimensions) in order to reach a

zero expanded pressure from any finite chamber pressure! In the real world, there is some finite space at the rear of the

stage, into which some appropriate number

of “vacuum engines” must actually fit. That

fit behind the stage is what limits the area expansion ratio.

The limitations are both the stage diameter and the length

of the space into which these engines must go,

and how that fit is determined also depends on the number of engines

selected, allowing for gimballing some,

but perhaps not all, of the

engines. Ultimately, this is driven by the thrust required at

stage ignition, the stage diameter to

meet fineness ratio requirements, and

the length available between that stage’s aft tank bulkhead and the top of the

lower stage.

My point:

vehicle design requirements determine allowable vacuum engine

expansion ratio, not the engine expansion

sizing alone. “Vacuum” engines have

larger expansion ratios, and better

thrust in vacuum, at the same flow rate

and chamber pressure, than their sea

level counterparts. But in general, they cannot be fired in the open air at sea

level, due to flow separation in the

bell that is induced by too much ambient atmospheric backpressure! Such separation leads to destruction the bell

in a matter of seconds, due to localized

overheating at the location where the shockdown occurs inside the bell.

These sea level and vacuum designs are the endpoints

of a possible spectrum of designs that could serve as “ascent engines”

between sea level and vacuum (outside the sensible atmosphere). Such ascent engines could be operated at sea

level near (or at) full chamber pressure,

with near-incipient separation,

resulting in an expansion ratio intermediate between the optimized sea

level and vacuum designs. If operated at

sea level at low chamber pressure,

separation ensues! Sea level

thrust is less than that of a true sea level design, because the exhaust is overexpanded, and suffers a very large backpressure

correction term on thrust. But performance

going out into vacuum is much better than a sea level design, while not quite as good as a “real” vacuum

design.

See Figure 15 for typical results, calculated for engines all sized to the same

chamber pressure and massflow rate (different bells fitted to the same power

head and throat area). The baseline

powerhead was the sea level engine.

Thrust level for sizing was set such that the same throat diameter and

total flow rate was obtained for all 3 engine designs. The 10 metric ton-force thrust class was

simply chosen arbitrarily. Rescale it at

need. Dimensions vary with square root

of thrust. Flow rates vary with

thrust. Isp does not rescale.

Figure 15 – Comparison of Sea Level, Ascent,

and Vacuum Designs

Bear in mind that there are multiple detailed choices for

the various parameters, so that the

final answers obtained are not always the same as these initial rough estimates, although they are always rather close to what

is depicted here. I sized the sea level

and ascent designs at max chamber pressure for this study.

80% max Pc might have been a better choice, especially for a higher-technology design at

higher max Pc. It is easier to ignite

and quickly ramp up to something like 80% power, than it is to ignite and quickly ramp up all

the way to full power. Full power starts

have been a “no-no” for many decades now,

starting with the engines in Von Braun’s V-2 rockets.

Regardless, the trend

is clear regarding good ascent engines for first stages and SSTO designs: you sacrifice a little thrust and Isp at sea

level for much better thrust and Isp out in vacuum, compared to a real sea level design. The vacuum performance of the ascent engine

design is still less than the performance of the “real” vacuum design, but it is a lot closer than the sea level

design ever could be. The

ascent-averaged Isp of the ascent design is rather close to its vacuum

level, and not all that far from the Isp

of the typical fit-limited “real” vacuum design.

Case Study:

All-Expendable SSTO

The overall bounding study indicated that only the LOX-LH2

expendable SSTO looks to be competitive with an all-expendable TSTO. Accordingly,

I came up with a modest-technology LOX-LH2 ascent engine sizing to

support such a design traceably, using

the “r noz alt mod” worksheet in the “liquid rockets.xlsx” spreadsheet. See Figure 16. I then used the “launch sizing.xlsx”

spreadsheet’s “SSTO exp” and “tank sizing” worksheets to size a vehicle of the

correct fineness ratio, complete with a total

thrust specification at liftoff. See

Figure 17.

Figure 16 – Engine Sizing Report for LOX-LH2 Ascent Engines

of Modest Technology

Figure 17 – Vehicle Sizing For an Expendable LOX-LH2 SSTO

Case Study:

All-Expendable TSTO

The overall bounding study indicated that the upper stage of

an all-expendable TSTO should be powered with modest-technology vacuum LOX-LH2

engines, while the lower stage could be

powered by either modest-technology LOX-LCH4 or LOX-RP1 ascent engines. I chose RP1 to get the benefit of the higher

fuel density.

Accordingly, I came

up with a modest-technology LOX-RP1 ascent engine sizing to support such a

design traceably, using the “r noz alt

mod” worksheet in the “liquid rockets.xlsx” spreadsheet. See Figure 18. I used the same tool to size a modest

technology LOX-LH2 vacuum engine. See Figure

19. I then used the “launch

sizing.xlsx” spreadsheet’s “TSTO exp” and “tank sizing” worksheets to size a

vehicle of the correct fineness ratio,

complete with a total thrust specification at liftoff, and at second stage ignition. See Figure 20.

Figure 18 – Engine Sizing Report for Modest-Technology

LOX-RP-1 Ascent Engine

Figure 19 – Engine Sizing Report for Modest-Technology

LOX-LH2 Vacuum Engine

Figure 20 – Vehicle Sizing Report for an Expendable

LOX-RP1/LOX-LH2 TSTO

Case Study: Feasibility of Reusable SSTO?

I used the “SSTO reU” worksheet in the “launch sizing.xlsx”

spreadsheet to investigate the possibility of a reusable SSTO, as a lifting body entry craft in order to

minimize its likely inert mass fraction.

Lifting body craft will have landing speeds in the 300 mph class. True winged craft will have landing speeds in

the 200 mph class, but also higher inert

mass fractions, to support wings

extended in near-broadside hypersonic flow without them being ripped off. The

worksheet has a means to crudely estimate what those inert mass fractions might

be. Strictly speaking, it is limited to the high engine

thrust/weight ratios of chemical engines,

especially in smaller vehicle sizes.

The first configuration estimated used the same

modest-technology LOX-LH2 ascent engine sizing that was used for the expendable

SSTO. Those results show clear infeasibility, as the leftover payload fraction is

negative, as indicated in Figure 21.

The second configuration in Figure 22 is the same

lifting body, just with the

ascent-averaged Isp raised (by about 27 sec) to represent a higher-technology LOX-LH2

engine. It still shows as infeasible, and by an amount comparable to the

modest-technology option. A little more

Isp (maybe 10 s) might be available, but

that clearly will not help.

The third configuration simply raises the ascent-averaged

Isp to a value more-or-less representative of what was achieved by the old

NERVA nuclear thermal rocket engine technology,

circa 1974. This shows to be

feasible, and at an attractive payload

mass fraction, although this performance

is likely over-estimated, since the low

thrust/weight ratio of the solid core nuclear engine is not correctly

modeled in the inert mass buildup options!

See Figure 23 for the (rather unreliable) numbers. They really only indicate some level of

feasibility, but not really by how much!

Bear in mind that the NERVA exhaust was radioactive, so this kind of nuclear technology is not

something you would really want to use in a reusable SSTO! However,

the Isp modeling this, is in a

class not approachable with any available chemical rocket technologies known

today! And THAT is the real

message here!

Figure 21 – Bounding Calculation for Modest-Technology

LOX-LH2 Reusable SSTO: Infeasible

Figure 22 – Bounding Calculation for High-Technology LOX-LH2

Reusable SSTO Still Infeasible

Figure 23 – Bounding Calculation for NERVA-Based Nuclear

Reusable SSTO: Feasible

About the “Orbits+” Courses:

This document details the how-to that corresponds to certain

lessons in the “orbits+” course set,

that is available for free download via the Mars Society’s “New Mars”

forums. Those lessons on vehicle

sizing, engine performance

estimation, and launch (specifically

from Earth) correspond to what is discussed here. This document presumes the reader is already

familiar enough with orbital mechanics to know how to estimate the velocity

requirements, that are factored-up to

cover losses. If not, the first few lessons in the course set, cover that topic.

By-hand analysis techniques still have a useful role to play

in all sorts of engineering disciplines,

not just space launch as is covered here. The models are simple, they have few inputs, and they do not require that a real design

with proper drawings has already begun.

The results are less precise, but

they are good enough to tell a good idea from a bad one. See Figure 24.

What that makes possible is two-fold: (1) you can quickly and cheaply screen a lot

of brainstormed ideas up-front, enabling

you to commit the significant resources of starting a real design, to only the best one or two ideas, and (2) if you can obtain approximate by-hand

estimates, you can better recognize

garbage-in/garbage-out problems with the computer-generated results of the full-blown

design process. Those two possibilities

can save you a ton of grief and money, over the long run.

Figure 24 – Where By-Hand Estimates Fit Into the “Big

Picture”

Where most people get into this launch stuff is by asking

the question “how big a rocket do I need to get to my desired

destination?” The answer is usually

obtainable with the classical rocket equation,

but only if you know how to use it properly! It needs the correct inputs for engine

performance and velocity requirements,

and the correct weight statement inputs to represent the various stages

or vehicles. These inputs in part are

theoretical (orbital mechanics), and in

part are quite empirical (loss factors, inert

mass buildups, etc.). The different topics (among those needed)

can lead the student to entirely-different destinations in terms of

skills, as shown in Figure 25.

Figure 25 – Where Most People Start: Asking Questions About Rockets

I laid out a series of course lessons aimed at bringing the

novice up-to-speed quickly and efficiently,

based on no math more difficult than high school algebra. Classical orbital mechanics requires multiple

presentation lessons to get the basics of the physics and how things interact

across to the student, before the

student is ready to attempt solving problems with it. This is indicated in Figure 26 as

lessons 1-3 for the presentations, and

lesson 3B as the corresponding problem-solving session.

There is a spreadsheet tool that makes running the 2-body

orbit numbers far easier in the 3B problem session. The problems start with solved demo problems

to show the student exactly how to do this,

then proceed to similar assigned problems for the student to work. The solutions to the assigned problems are

provided, in order for the student to self-assess

how well he/she did.

Launch is a more empirical topic, complete with ways to estimate what are

called gravity and drag losses. Those

losses have to add to the velocity requirements that size the vehicle. This is

covered in lesson 4, with 4B as the

problem-solving session.

The problem of interplanetary transfers is covered for

min-energy Hohmann transfers in lessons 5 and 5B, and for faster transfers in lessons 5.5 and

5.5B. There are both theoretical orbital

mechanics and some empirical real-world effects that are parts of these lessons

(such as mid-course correction budgets). The lessons suffixed with B’s are the

problem sessions.

Lessons 6 and 6B cover the basics of the entry, descent,

and landing problem, to include

some very empirical real-world items necessary for doing any of this. The more detailed ability of estimating entry

dynamics and heating is covered in lessons 7 and 7B, supported by a spreadsheet adaptation of the

old by-hand estimates made in the mid-1950’s for warhead entry, updated.

Lessons 8 and 8B cover the basics of doing custom

spreadsheets to link multiple rocket equation burn analyses and weight

statements together, in order to

determine estimated vehicle performance (the topic of this article. There is an oversimplified spreadsheet tool

available for bounding calculations, but

the student will, by this time, need to do his own custom spreadsheets, with multiple rocket equation analyses linked

together and done in correct order.

Lessons 9 and 9B cover how to create reliable estimates of

liquid rocket engine performance from few inputs. The engine “cycle” that drives the turbopumps

is not addressed, except that its dumped

gas bleed fraction is needed to get a reliable specific impulse figure. Scope is limited to fixed expansion

bells, and some appropriate empirical

factors are included.

Figure 26 – What Are The “Orbits+” Course Offerings

All the course topic areas are covered in the same way, as indicated in Figure 27. There is one or more “present the basics”

lessons that resemble lectures, followed

by one (or more) problem-solving sessions.

These include working a demo for the students, followed by assigning similar problems to the

students. Solutions to the student

problems are provided for self-check on how well the student did. Each lesson

has a course text document, and an

associated slide set for teaching it to others,

plus supporting spreadsheets and user manuals as needed. As indicated in

Figure 28, the course materials

can be obtained via links posted on the Mars Society’s New Mars forums. Direct links to the supporting spreadsheets

are located just ahead of Figure 9 above.

Figure 27 – How the Courses Are Structured

Figure 28 – Where Most of the Course Materials Can Be

Downloaded For Free

Final Comments

I first did this kind of rocket equation thing for a living,

as a graduate student while taking a

summer off, to work at what was then LTV

Aerospace’s Marshall Street Facility,

working in the “Scout” launcher group.

I sized 1-off configurations and advanced launcher designs, plus I helped with orbital analysis for

customer satellite launches. I did

exactly these kinds of hand calculations in order to set up design models of what

I wanted to “fly” with LTV’s “NEMAR” launch trajectory code.

This sort of by-hand analysis to set up real design efforts

was exactly what I did working for Rocketdyne/Hercules in McGregor, Texas,

once I left graduate school. I

did this for both rockets and ramjets,

particularly the booster rockets for the ramjets. Once again,

this sort of thing sets up the actual design efforts, the exploratory testing, and the planning of what to pursue next.

I did some of this same by-hand work at what was then Tracor

Aerospace in Austin, Texas, between two tours at the McGregor rocket

plant. I did this kind of thing for both propulsive decoy items, and for towed decoy items (a different subject

not involving the rocket equation).

Again, it helped screen candidate

ideas in a cost-effective fashion, it

helped set up real design efforts, it

helped determine exploratory testing,

and it helped guide the planning.

I (and all the colleagues around me) started out doing this

sort of thing pencil-and-paper, running

numbers with a slide rule, most of the

time. Only occasionally, when there was no other way, we would run a software code model on the

computer, which in those days was an

enormous power-consumptive mainframe, which

you communicated with by batch runs of punch cards in a steel tray, and waited hours before your results ever came

back.

We quickly converted to scientific calculators, but it was still literally pencil-and-paper

work. Desktop computers were still years

in the future, and spreadsheet software

years after that. But since those

times, I have maintained my abilities to

do by-hand engineering design analysis,

assisted now by both calculators and modern spreadsheet software. The spreadsheets offer a fast way to iterate

solutions, and to plot your data.

To see what the old style tools once were, see Figure 29. Some of you may not know what a slide rule

is! It did what today’s calculators

do, for about 300 years before there was

any such thing as a calculator.

Other than that, I

would invite interested persons to visit the New Mars forums site for more than

just the free downloads of the stuff I have put together on this rocket vehicle

sizing subject. Poke around, and see all the various things forums

participants have discussed. Such might

be of considerable interest to you.

Consider also becoming a member and participating. To do so,

contact newmarsmember@gmail.com.

Figure 29 – Old Style Engineering Tools, Circa 1960’s and 1970’s

No comments:

Post a Comment